Friction fixing anchor rod

A fixed bolt technology, which is applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problems affecting the installation of waterproof boards, the leakage of grouting fluid, and the exposed end of bolts is too long, so as to achieve reliable working principle , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

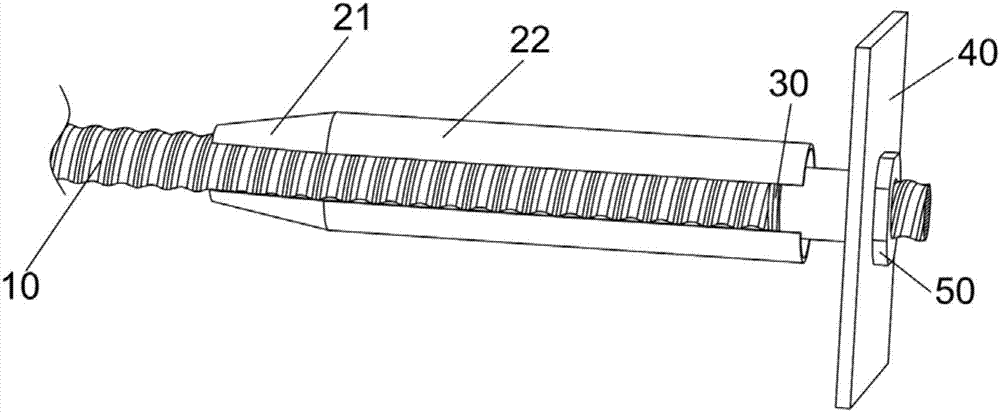

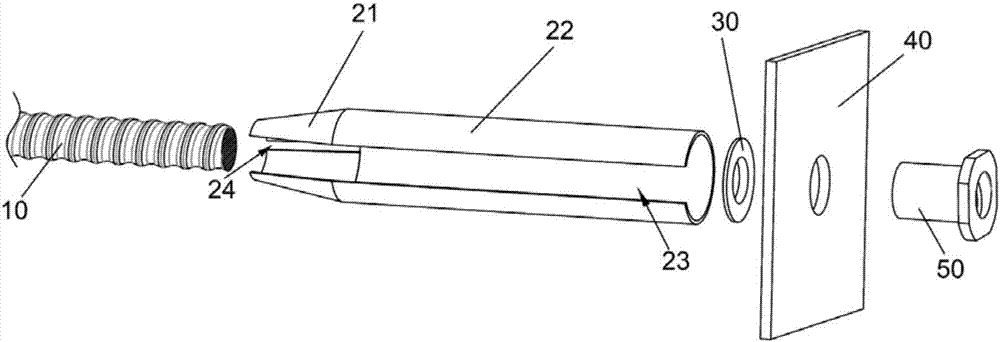

[0029] This embodiment provides a friction-fixed bolt, as attached figure 1 , attached figure 2 And attached Figure 5 As shown, countersunk nuts are selected in this embodiment, and the friction-fixed bolt includes a bolt body 10, and the outer surface of the bolt body 10 is set as a full thread, which is characterized in that it also includes a friction fixing sleeve and a sealing ring 30 , backing plate 40 and nut 50;

[0030] The friction fixing sleeve is set as a pipe body provided with a press-fit opening 23 along the length direction of the friction fixing sleeve. The friction fixing sleeve includes an integrally formed front tapered diameter reducing section 21 and a rear end straight pipe section 22. The tapered diameter reducing section A fastening port 24 is provided, and the anchor rod body 10 is arranged in the friction fixing sleeve. When the friction fixing sleeve is pushed into the anchor hole, the opening pipe body is compressed from large to small, and a l...

Embodiment 2

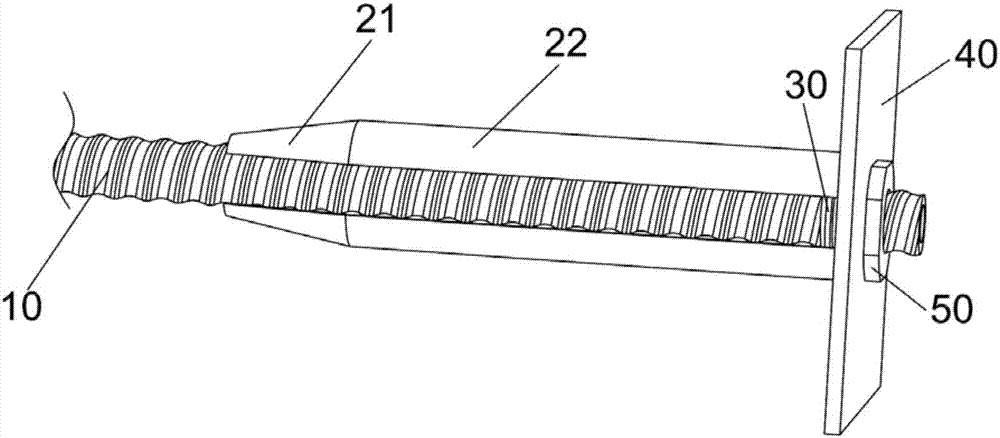

[0041] This embodiment provides a friction-fixed bolt, as attached image 3 , attached Figure 4 And attached Figure 5 As shown, in this embodiment, a hexagonal nut is selected. The friction-fixed bolt includes a bolt body 10, and the outer surface of the bolt body 10 is set to be fully threaded. It is characterized in that it also includes a friction fixing sleeve, a sealing ring 30, Backing plate 40 and nut 50;

[0042] The friction fixing sleeve is set as a pipe body provided with a press-fit port 23 along the length direction of the friction fixing sleeve. The friction fixing sleeve includes an integrally formed front tapered diameter reducing section 21 and a rear end straight pipe section 22. The tapered diameter reducing section A fastening port 24 is provided, and the anchor rod body 10 is arranged in the friction fixing sleeve. When the friction fixing sleeve is pushed into the anchor hole, the opening pipe body is compressed from large to small, and a large fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com