Heating type water storage structure for humidifier and humidifier comprising same

A humidifier and heating technology, used in heating methods, air humidification systems, lighting and heating equipment, etc., can solve the problems of large influence of heating elements, dry heating of the heating plate, and increase the cost of the whole machine, so as to avoid dry heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described below based on examples, but the present invention is not limited to these examples. Those of ordinary skill in the art should understand that the drawings provided herein are for illustrative purposes, and the drawings are not necessarily drawn to scale.

[0031] Unless the context clearly requires, the words "including", "including" and other similar words in the entire specification and claims should be interpreted as inclusive rather than exclusive or exhaustive meanings; in other words, "including but not limited to" Meaning.

[0032] In the description of the present invention, it should be understood that the terms "first", "second", etc. are only used for descriptive purposes and cannot be understood as indicating or implying relative importance. In addition, in the description of the present invention, unless otherwise specified, "plurality" means two or more.

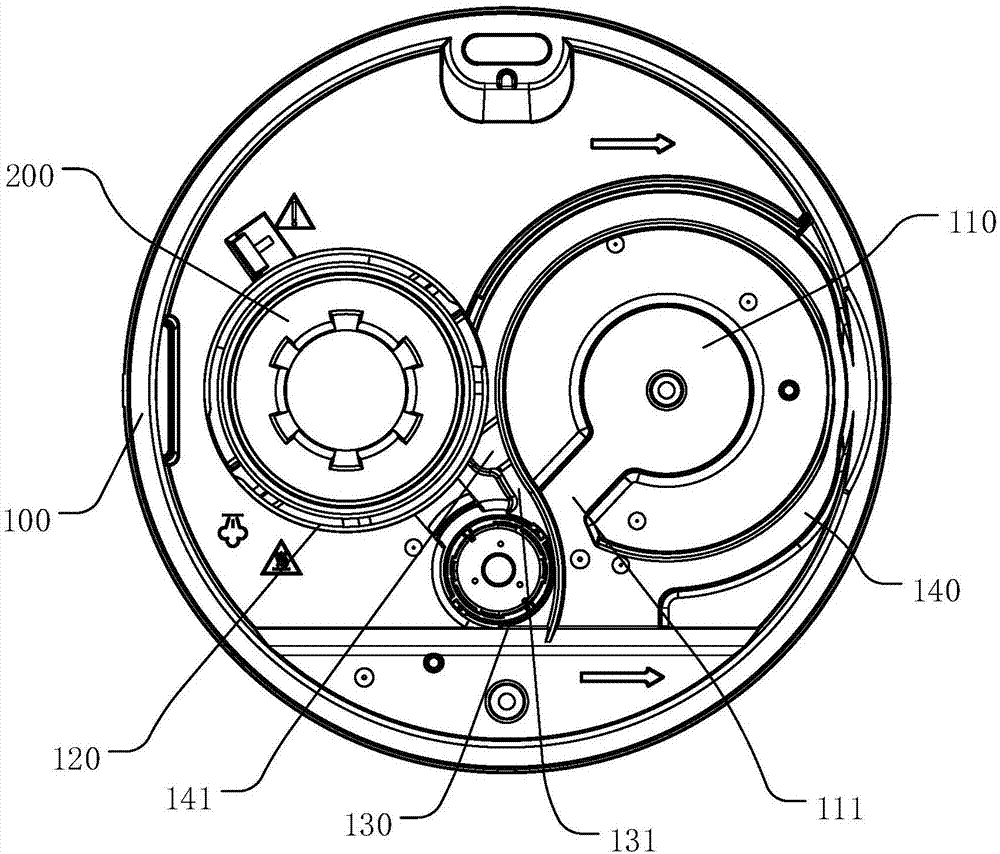

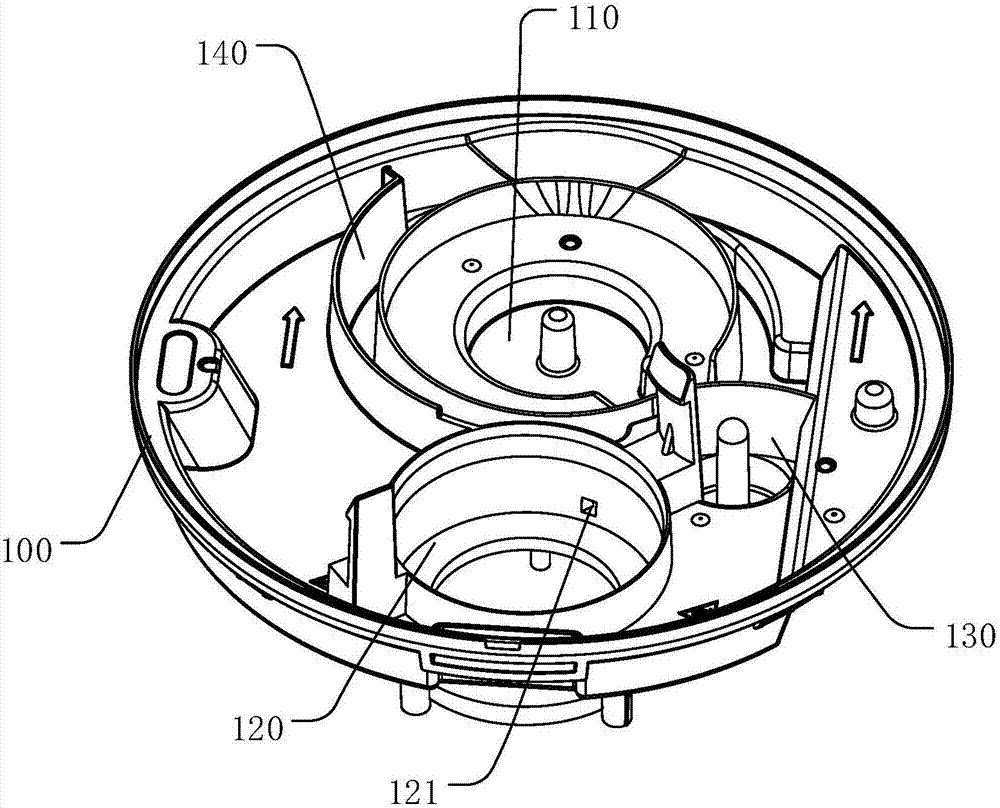

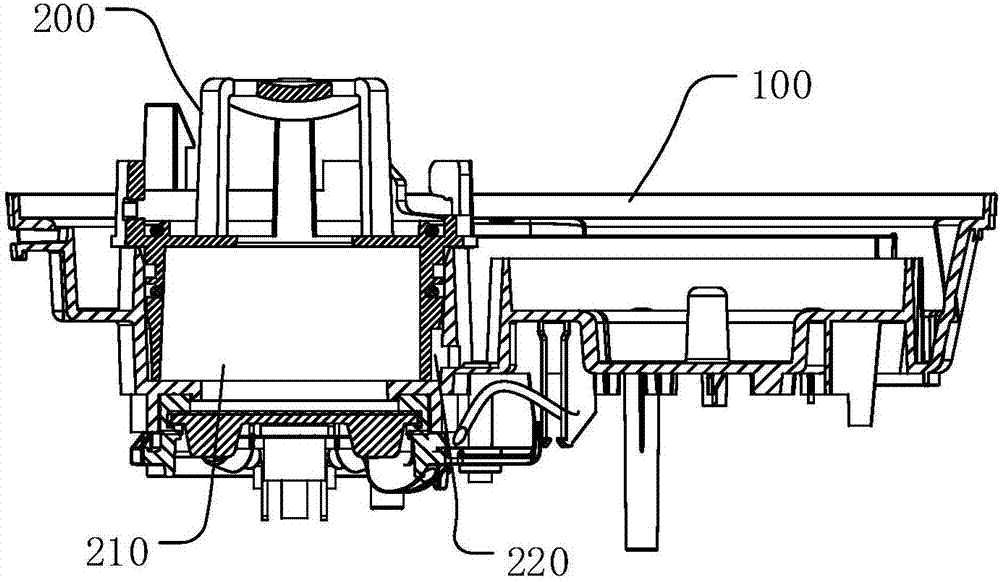

[0033] The water storage structure of the heating type humidifier prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com