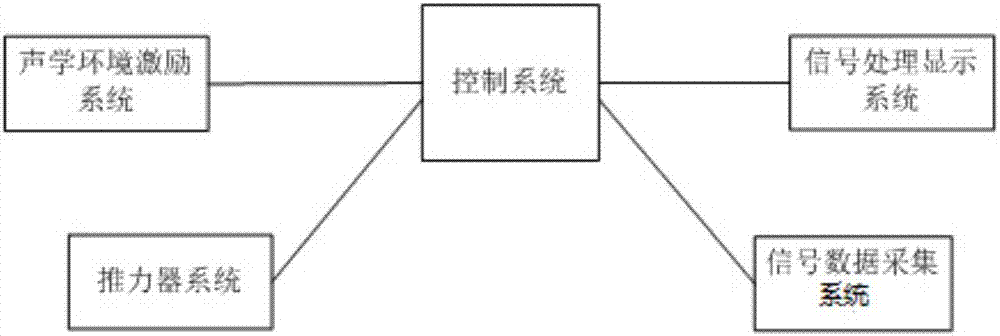

Acoustic elasticity technology-based electric propulsion field micro-thrust transient measurement system

A measurement system, acoustic elasticity technology, applied in the direction of force/torque/power measuring instrument, measuring device, instrument, etc., can solve the problems of thruster electromagnetic interference, unable to measure the thruster's transient thrust value, etc., to solve the zero point drift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

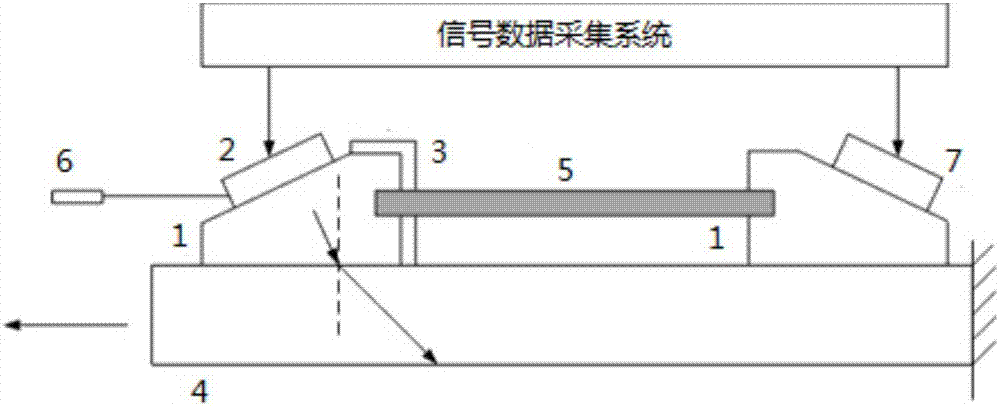

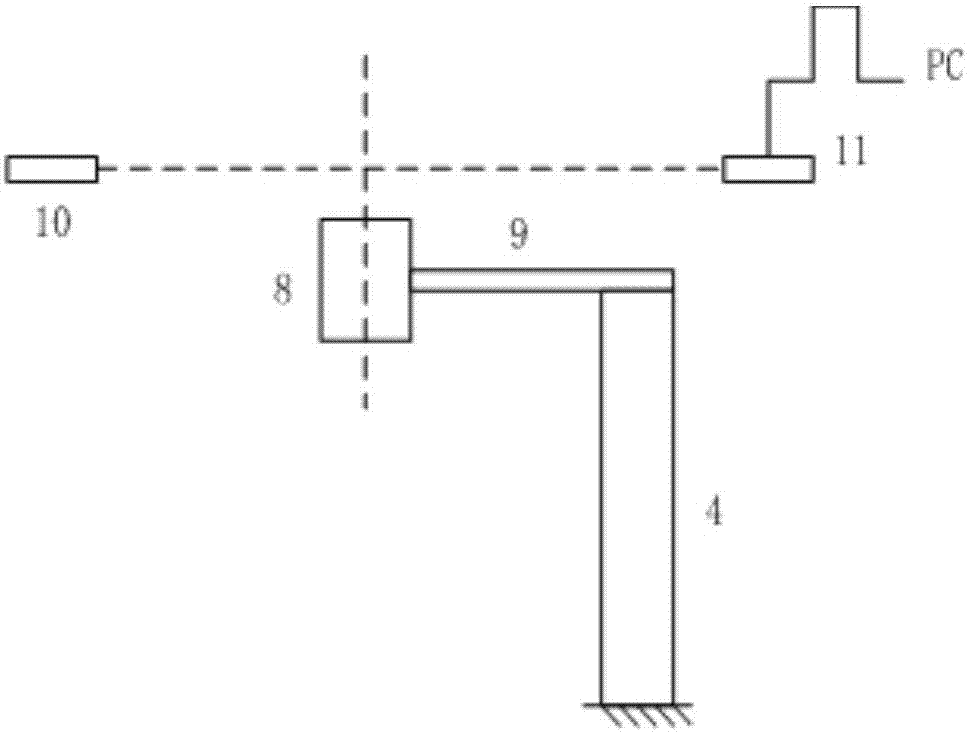

[0041] A measuring instantaneous thrust system based on the acoustoelastic method, through measuring the acoustic time change caused by the force, showing the magnitude and distribution of the force. At the same time, when the high-precision measuring chip is used to record the sound, it approximately reflects the real-time changes of the thruster. The present invention is a non-contact measurement method, which is also a non-destructive measurement method. It does not need to directly install sensors or other measuring devices on the structure, and can reduce the interference of mechanical vibration and power supply cables on thrust measurement. There are problems such as zero point drift, unstable balance position, difficult calibration and low precision in the impulse measuring device. The invention applies the acoustoelastic method to the measurement field of thruster transient thrust, and has the advantages of simple structure, easy operation and high reliability, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com