Linear motor traction system cogging force reduction method

A traction system, linear motor technology, applied in control systems, AC motor control, motor speed or torque control, etc., to achieve the effects of easy production, improved thrust fluctuation performance, and improved train running quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing;

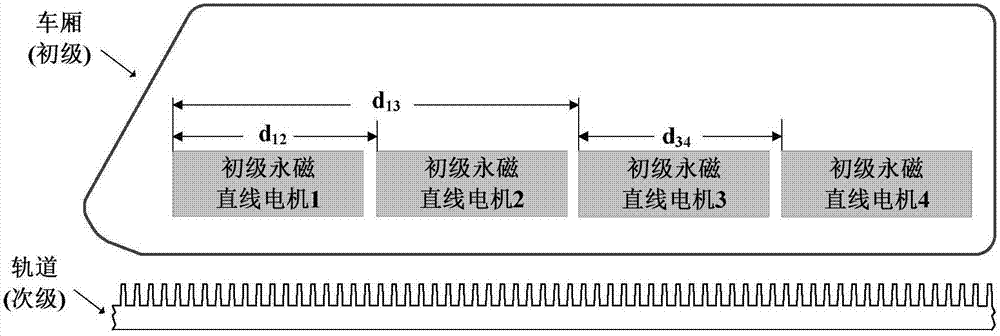

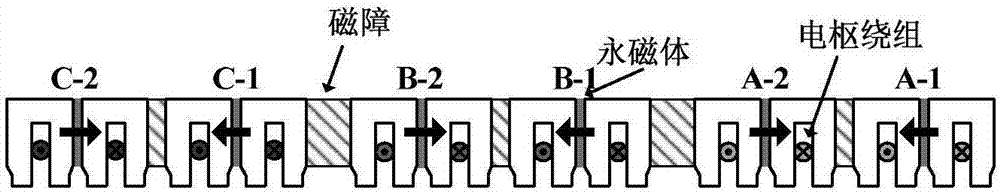

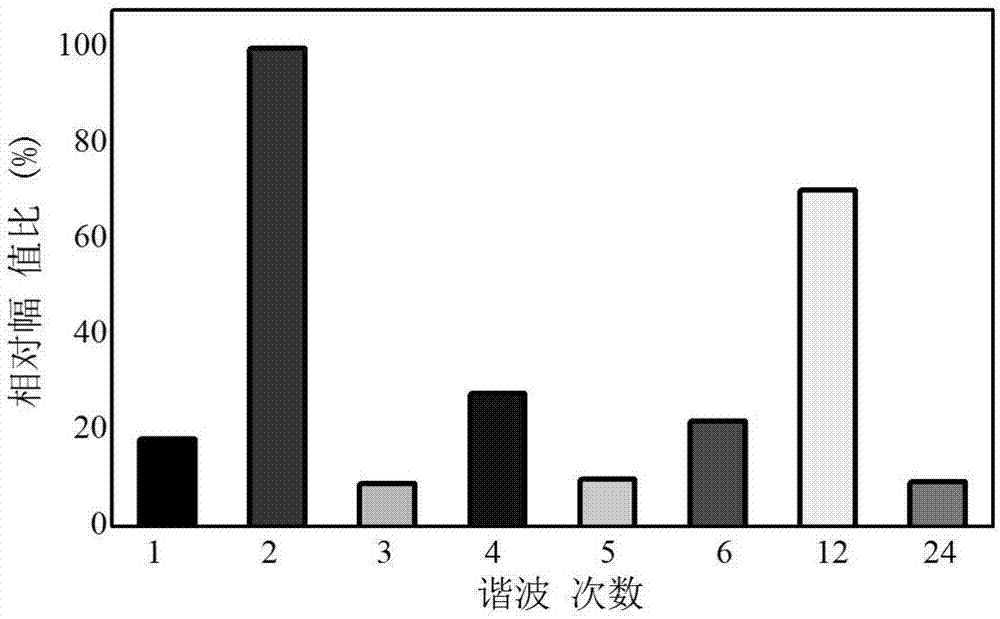

[0023] as attached figure 1 As shown, a method for reducing positioning force of a linear motor traction system disclosed in an embodiment of the present invention, the traction system includes four identical three-phase primary permanent magnet linear motors; the first primary permanent magnet linear motor 1 and the second primary permanent magnet linear motor The spatial distance of the linear motor 2 (the distance between the two starting ends) is d 12 , the space distance between the first primary permanent magnet linear motor 1 and the third primary permanent magnet linear motor 3 is d 13 , the spatial distance between the third primary permanent magnet linear motor 3 and the fourth primary permanent magnet linear motor 4 is d 34 . as attached figure 2 As shown, each primary permanent magnet linear motor includes three-phase modules, each phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com