Industrial control system detection method and device

A technology of industrial control system and detection method, which is applied in the direction of transmission system, electrical components, etc., can solve the problems of long-term cycle, blind scanning of the host computer, long scanning time, etc., and achieve high precision, shortened overall time, scanning time and overall efficiency and the effect of improving the fault tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to understand the characteristics and technical contents of the embodiments of the present invention in more detail, the implementation of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The attached drawings are only for reference and description, and are not intended to limit the embodiments of the present invention.

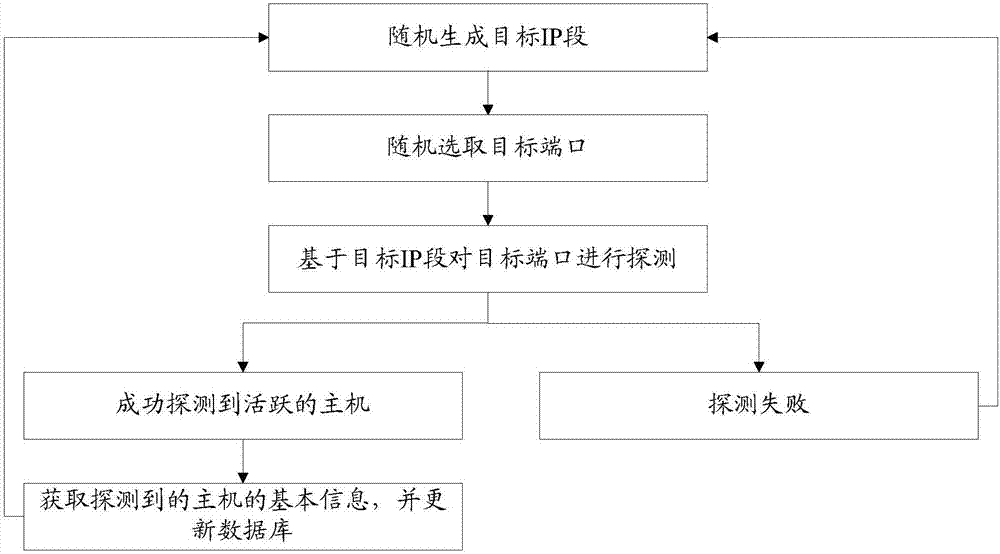

[0049] The technical scheme of the embodiment of the present invention is divided into two steps as a whole, specifically as follows:

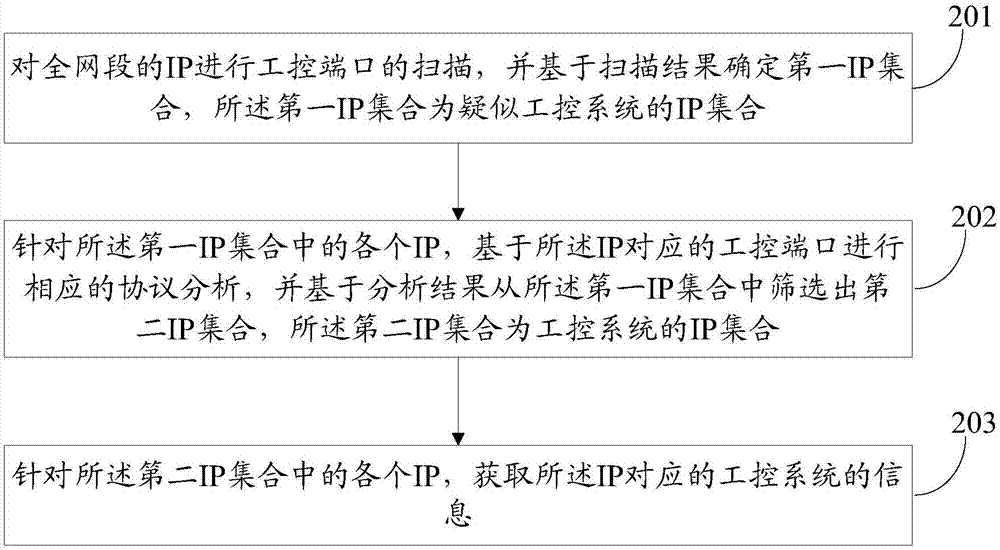

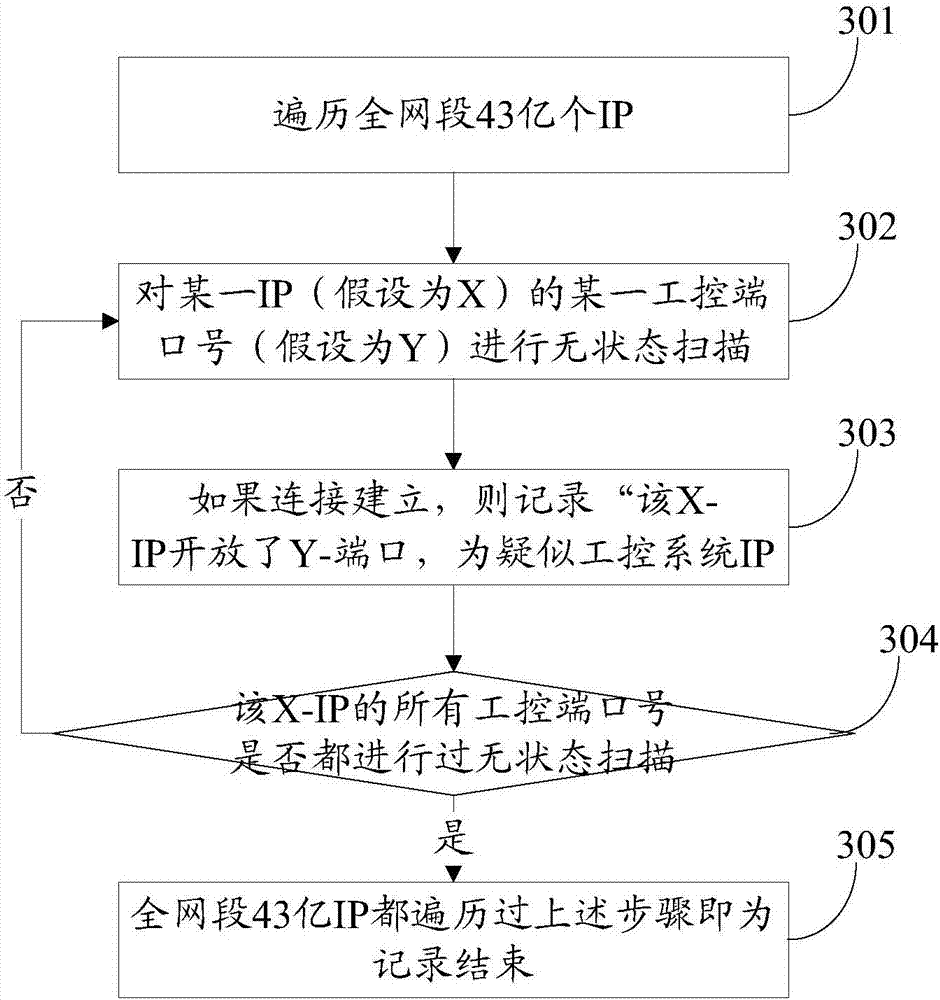

[0050] Step 1: Because industrial control systems have open IPs and ports, through extremely fast scanning, detect the openness of industrial control ports of nearly 4.3 billion IPs in the entire network, and obtain the IP collection of suspected industrial control systems.

[0051] Step 2: In the obtained IP collection of suspected industrial control systems, analyze the port protocol according to the open industrial control ports. If it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com