Cabinet system

A cabinet and backplane technology, used in cooling/ventilation/heating renovation, electrical components, electrical equipment structural components, etc., can solve the problems of limited heat dissipation openings, low heat dissipation efficiency, etc. Solve the effect of low heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

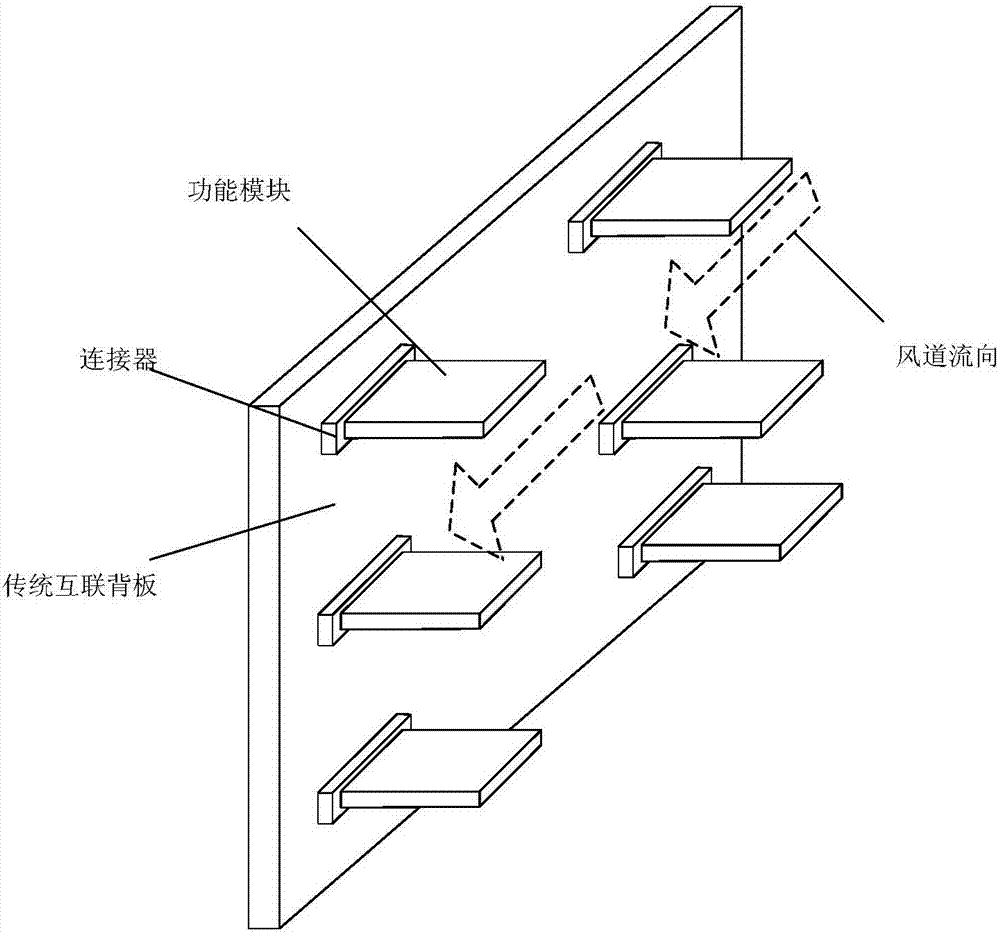

[0033] Figure 4a is a schematic front view of a cabinet system according to an embodiment of the present invention, Figure 4b is a top view of a cabinet system according to an embodiment of the present invention, such as Figure 4a and Figure 4b As shown, the cabinet system 1 includes: a backplane device 1-1 composed of 2N+1 sub-backplanes, a function board 1-2, and a fan 1-3;

[0034] Wherein, the sub-backplane includes: a first interconnection backplane 1-1-1 and a second interconnection backplane 1-1-2; every two first interconnection backplanes 1-1-1 are provided with a second interconnection Backplane 1-1-2;

[0035] The functional board 1-2 is horizontally arranged between the first interconnected backplane 1-1-1 and the second interconnected backplane 1-1-2, and is connected to the first interconnected backplane 1-1-1 and the second interconnected backplane respectively. Backplane 1-1-2 horizontal orthogonal connection;

[0036] The fans 1-3 are arranged between...

Embodiment 2

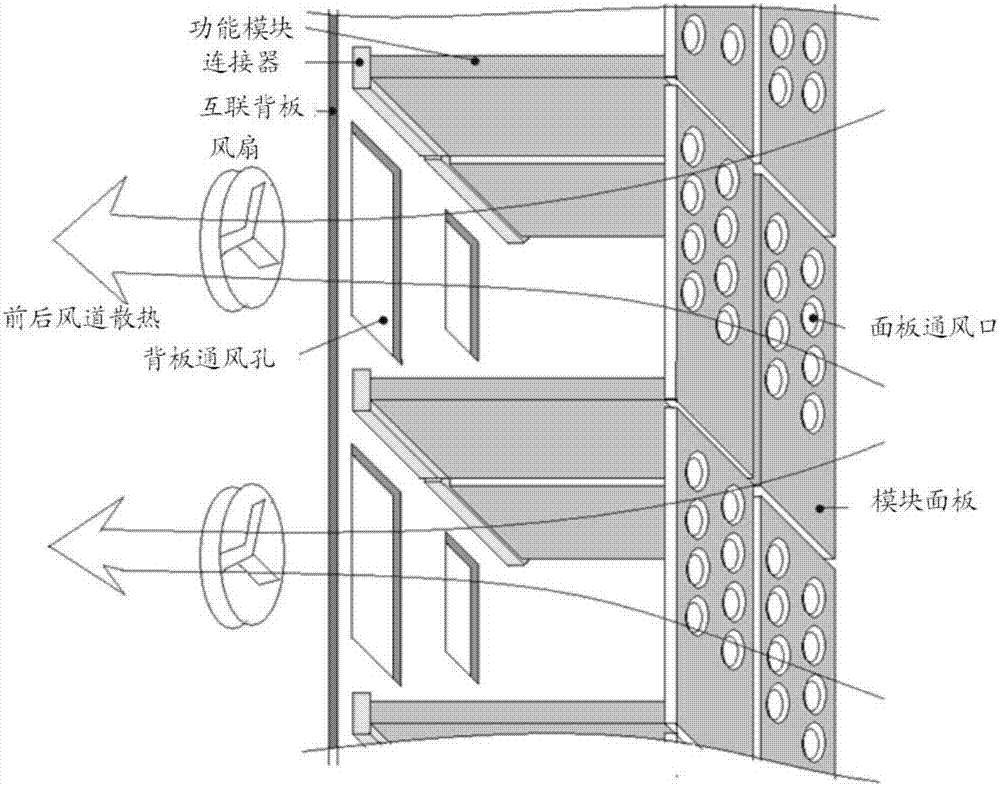

[0043] The cabinet system 1 involved in this embodiment also includes connectors 1-4, such as Figure 5a and Figure 5b as shown, Figure 5a~5b is a schematic structural diagram of a cabinet system including a connector according to an embodiment of the present invention;

[0044] Among them, the connector 1-4 includes: a first connector 1-4-1 arranged on the same side of the first interconnected backplane as the second interconnected backplane; a second connector arranged on both sides of the second interconnected backplane 1-4-2; the third connector 1-4-3 arranged on the function board and connected orthogonally to the first connector 1-4-1; arranged on the function board and connected to the second connector 1-4 - 2 fourth connectors 1-4-4 of orthogonal connection; the third connector 1-4-3 is in conduction with the fourth connector 1-4-4.

[0045] It should be noted that the third connector 1-4-3 and the fourth connector 1-4-4 involved in this embodiment can be disposed...

Embodiment 3

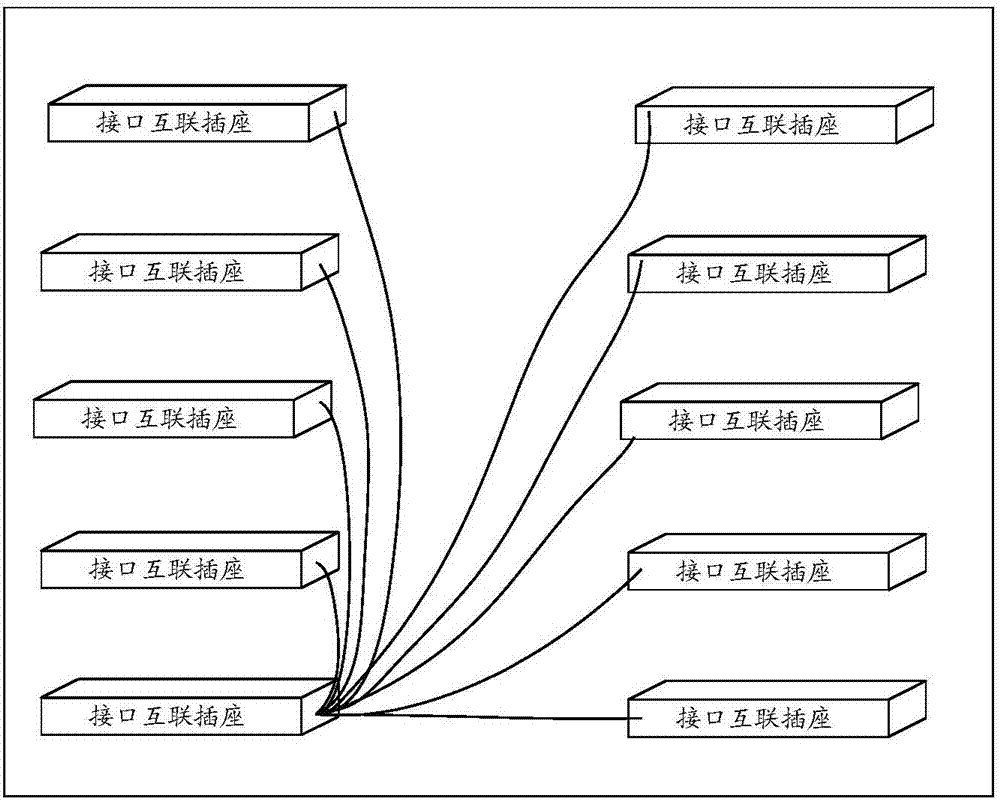

[0048] This embodiment is the implementation of the above-mentioned Embodiment 1 and Embodiment 2 in a specific application scenario. This embodiment uses a cabinet as an example to illustrate the present invention. The full Mesh positive interactive online cabinet system, such as Figure 6 as shown, Figure 6 It is a schematic structural diagram of a cabinet system including a backplane device according to an embodiment of the present invention Figure 1 ;

[0049] The cabinet system includes: a backplane device, wherein the backplane device includes three sub-backplanes: an upper and lower interconnected backplane 1 (corresponding to the first interconnected backplane in the above-mentioned embodiment), and an upper and lower interconnected backplane 2 (corresponding to the above-mentioned The first interconnection backplane in the embodiment), the horizontal interconnection backplane (corresponding to the second interconnection backplane in the above embodiment), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com