Empty boiling prevention heating pot

A technology of anti-dry heating and heating device, which is applied to water boiling utensils, cooking utensil lids, cooking utensils and other directions, can solve problems such as danger and dry heating of heating pots, and achieves increased production cost, easy debugging and installation, and good practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

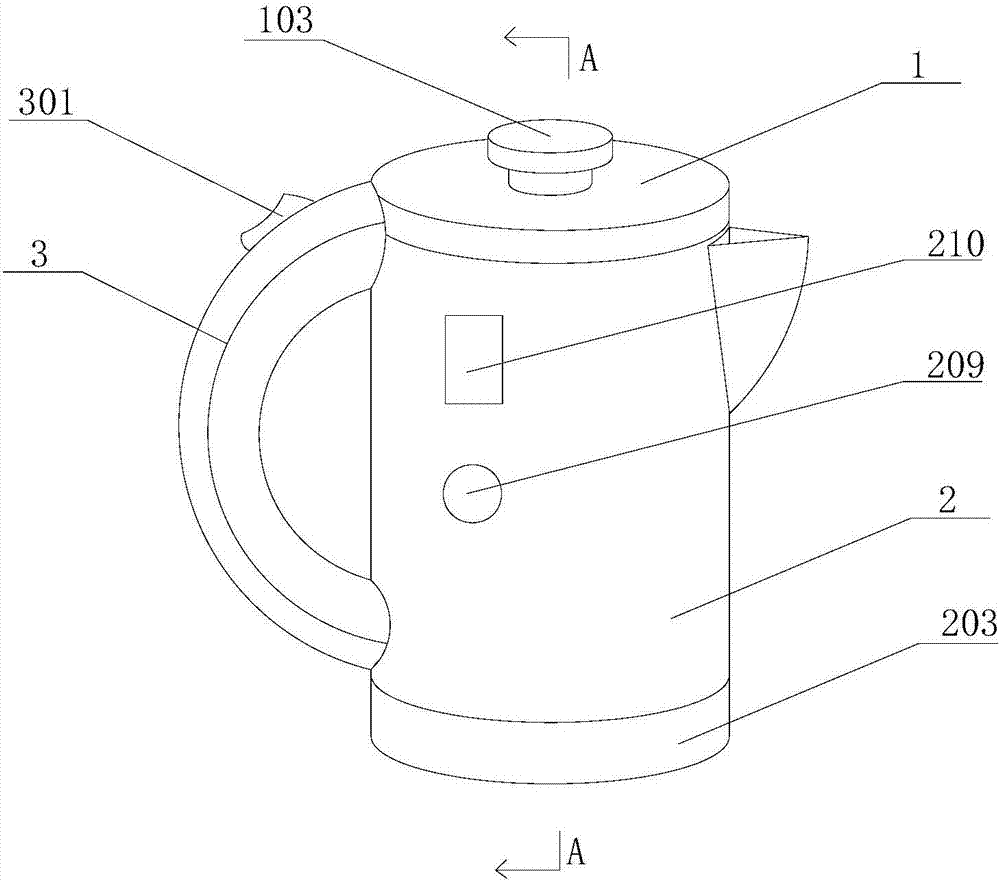

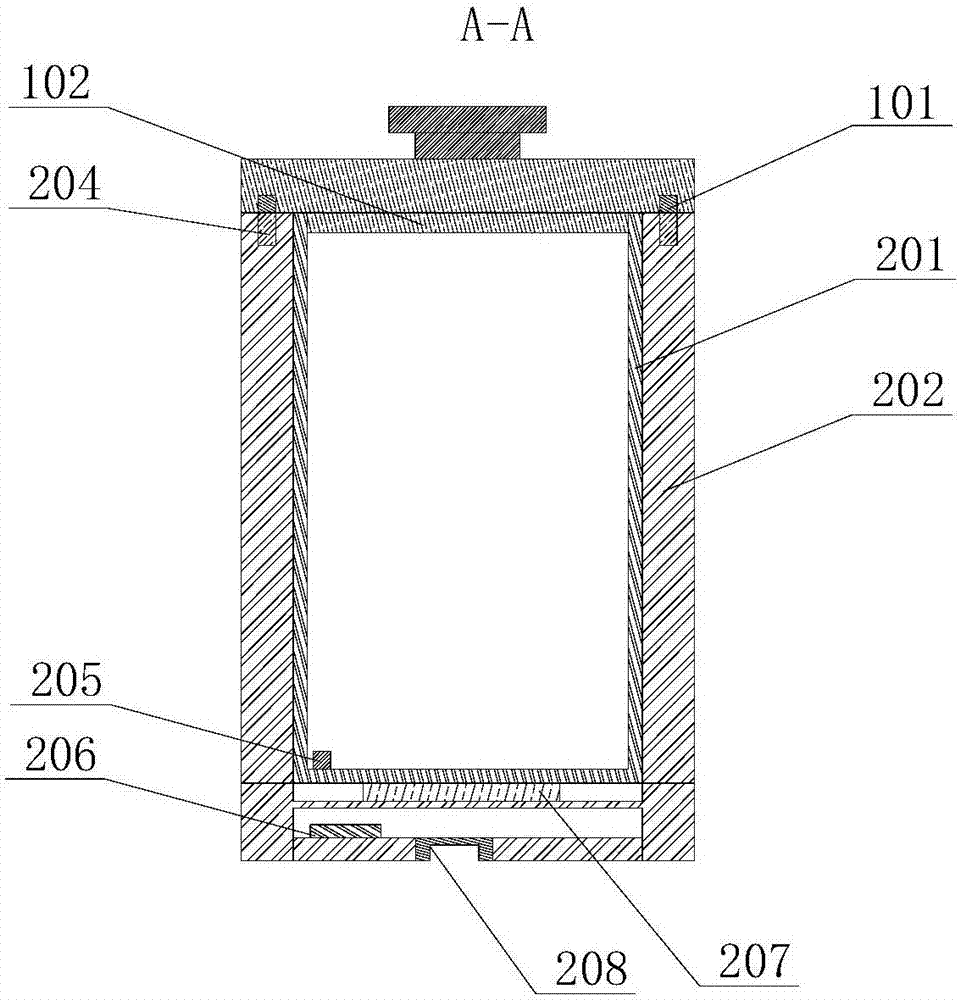

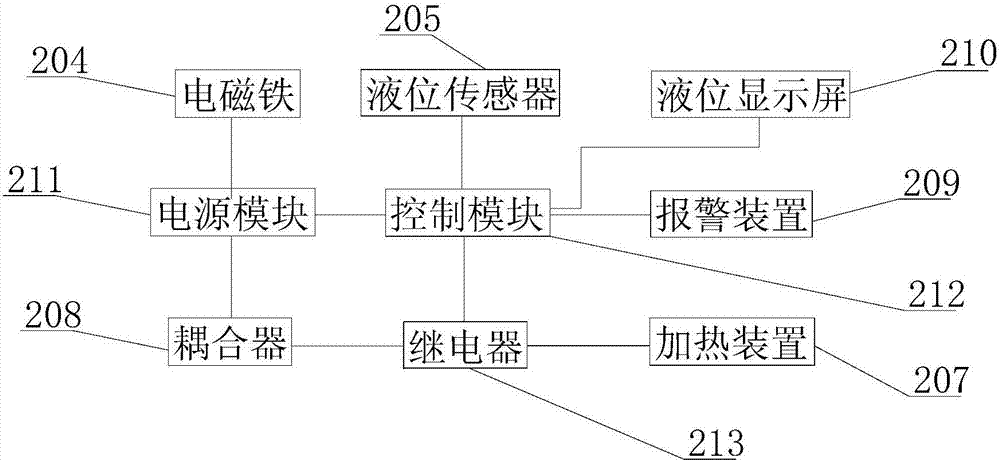

[0028] Such as figure 1 , 2 As shown, an anti-dry heating pot includes a pot body 2 and a pot cover 1 , and the pot body 2 includes an inner pot body 201 and an outer shell body 202 . A liquid level sensor 205 is arranged on the inside of the bottom of the inner jug body 201 . The outer casing 202 is installed on the outside of the inner kettle body 201 , a handle 3 is arranged on the outer peripheral surface of the outer casing 202 , and a steam switch 301 is arranged on the handle 3 . The outer peripheral surface of the outer shell 202 is provided with a liquid level display screen 210. The setting of the liquid level display screen 210 enables the user to clearly understand the internal water level of the inner jug body 201, so that the user can add or subtract water according to the demand. An alarm device 209 is also provided on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com