Device for bridge construction

A bridge and rotating shaft technology, applied in the field of bridge construction devices, can solve the problems of difficult maintenance, complex internal structure, and inability to pour out in batches, so as to improve work efficiency, facilitate operation, and improve automation control rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

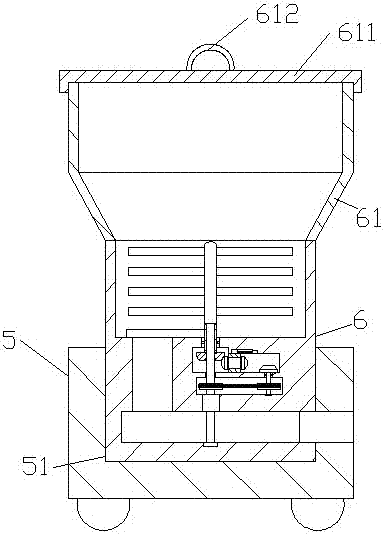

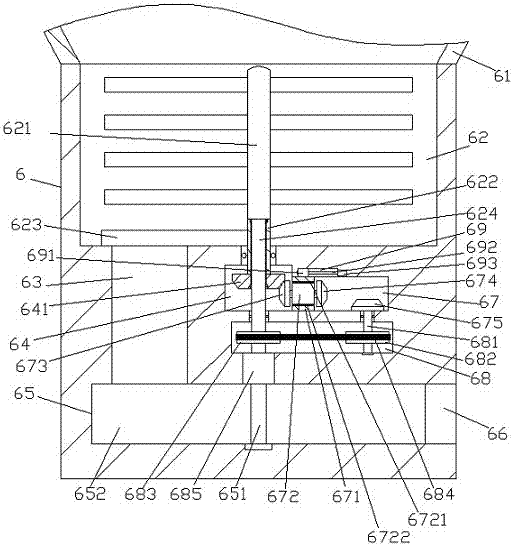

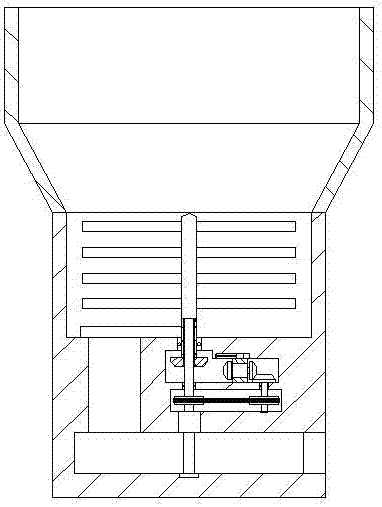

[0018] like Figure 1-Figure 4 As shown, a bridge construction device of the present invention comprises a base 5 and a concrete box 6, the top tail end of the right side of the base 5 is provided with a box groove 51, and the concrete box 6 is installed in the box groove 51 And fixedly connected, the top of the concrete box 6 is provided with a funnel 61, the concrete box 6 below the bottom of the funnel 61 is provided with a stirring chamber 62, and the inner bottom wall on the left side of the stirring chamber 62 is provided with a downward The excavation opening 63 that is extended, the bottom of the excavation opening 63 is extended and the tail end is connected with a batch chamber 65 that is extended to the right, and the concrete box 6 below the center of the mixing chamber 62 is provided with a first The conduction chamber 64, the rotation sleeve 622 extending up and down in the concrete box 6 between the first conduction chamber 64 and the mixing chamber 62 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com