Patents

Literature

46results about How to "Improve unearthed efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

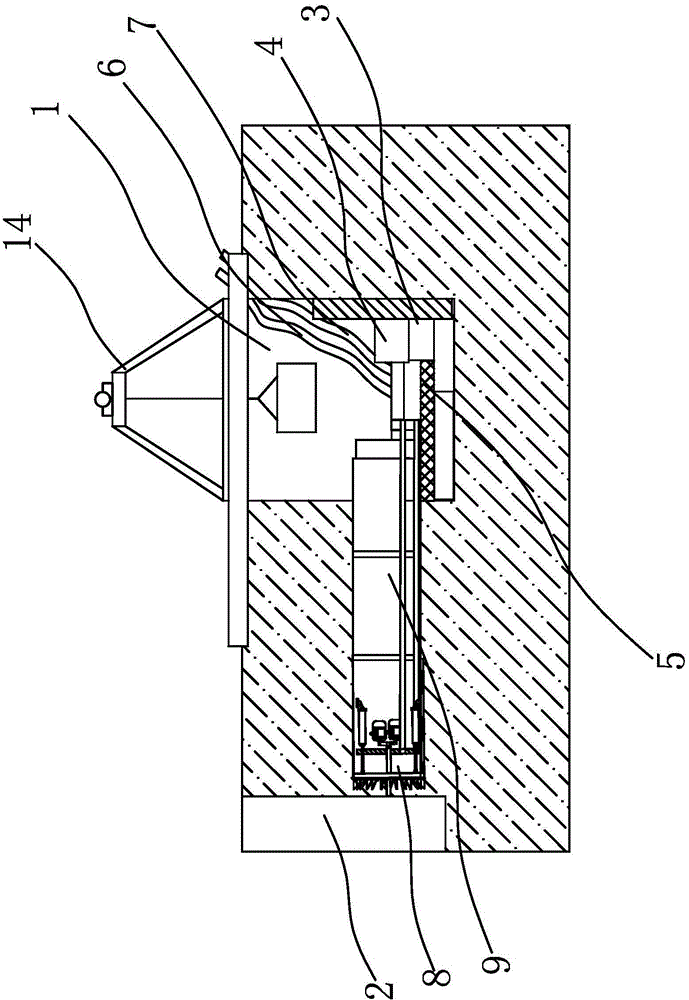

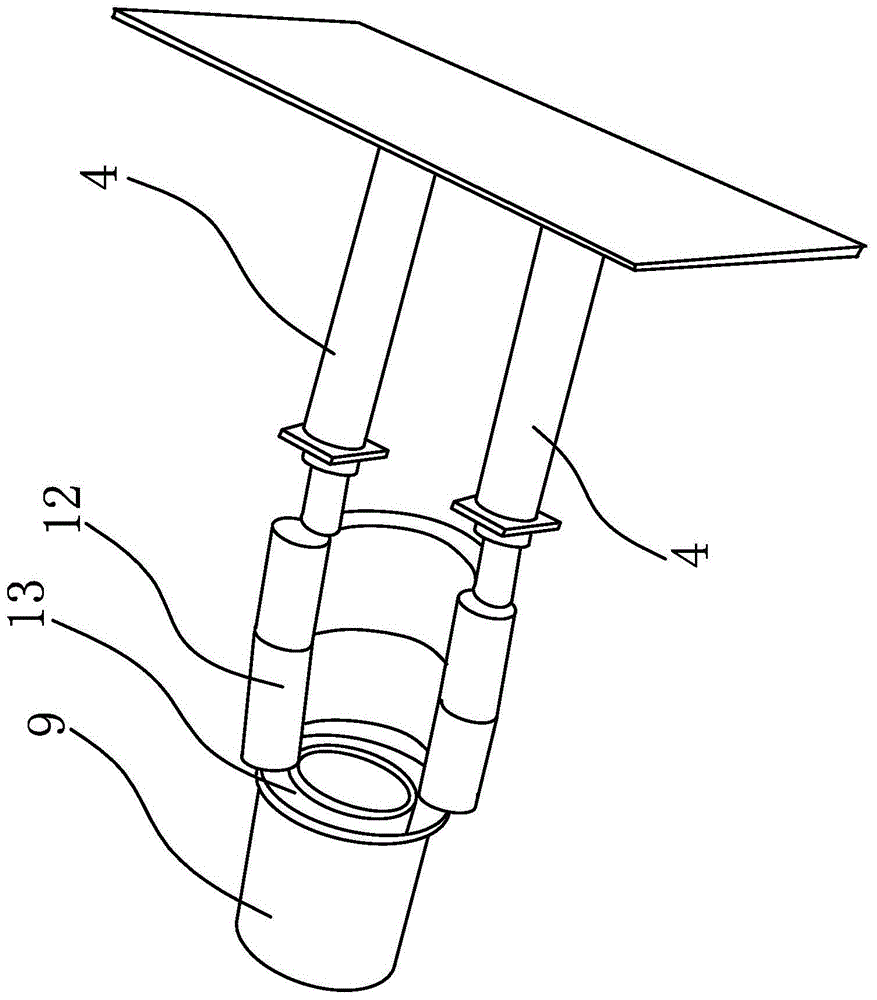

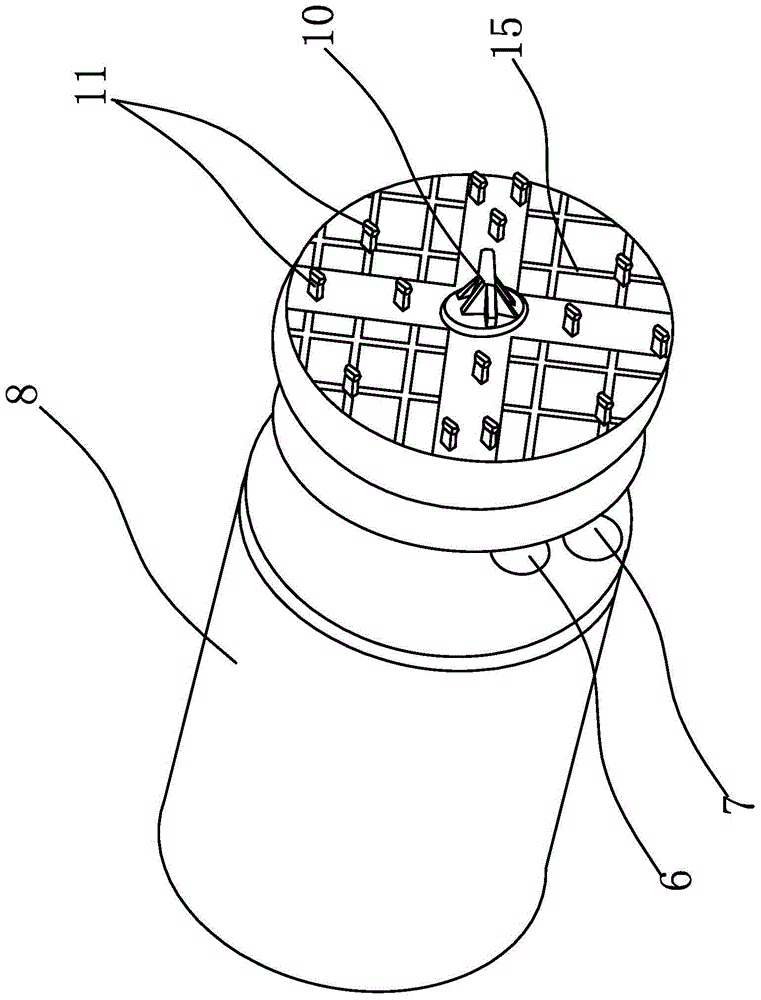

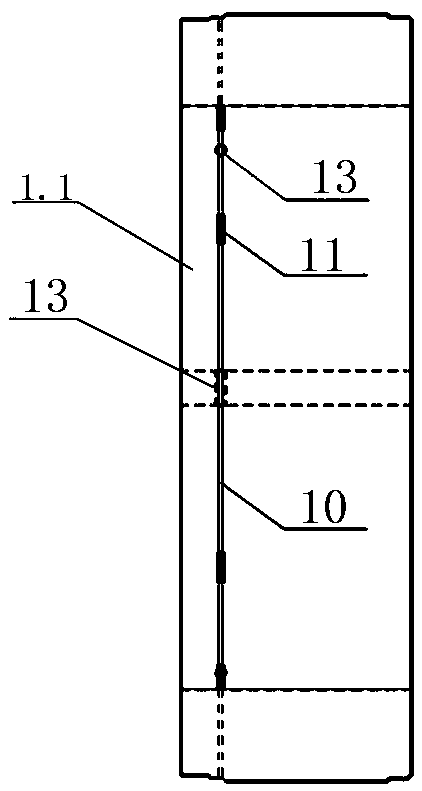

Push pipe construction method and push pipe device

ActiveCN104358927ASave human effortImprove unearthed efficiencyPipe laying and repairDischarge efficiencyWater flow

The invention provides a push pipe construction method and a push pipe device, and belongs to the technical field of architectural engineering equipment. The technical problems such as low construction efficiency of the conventional push pipe construction method are solved. The construction method comprises the following steps: a, digging a well; b, mounting equipment; c, jacking a drill head of the push pipe; d, jacking a pipeline; e, pumping mud; f, taking out a machine head, and the like. The push pipe device comprises jacks, a jack bracket, a sliding rail and a push pipe drill head, wherein the jacks are arranged on the jack bracket; the push pipe drill head is arranged on the sliding rail; telescopic rods of the jacks are towards the push pipe drill head; a circular back is arranged between the jacks and the push pipe drill head, and the circular back is attached to the end part of the push pipe drill head; the front end of the push pipe drill head is connected with a water inlet pipe and a mud outlet pipe, and hoisting equipment is also arranged above the sliding rail. According to the invention, in the process of jacking, water can be injected into the front end of the push pipe drill head through the water inlet pipe, excavated soil is changed into slurry by water currents, the slurry is discharged out of the mud outlet pipe, and the soil discharging efficiency is improved.

Owner:GUOQIANG CONSTR GRP

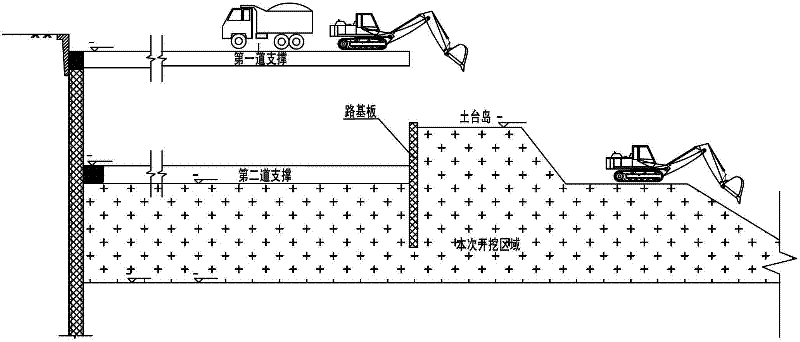

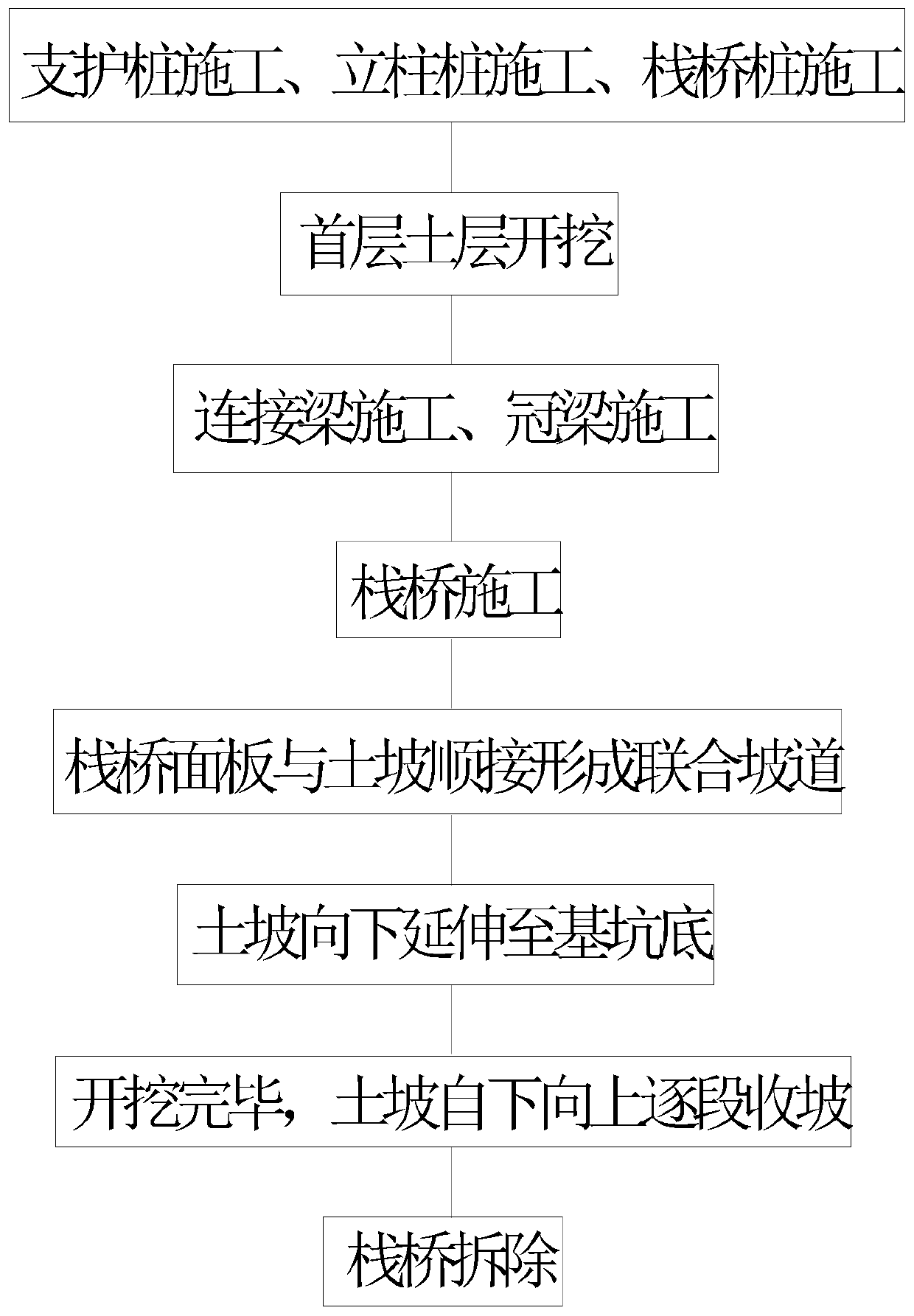

Construction method of foundation pit earthwork

ActiveCN102691300AImprove unearthed efficiencyShorten the construction periodExcavationsDeep excavationBuilding construction

The invention relates to a construction method of foundation pit earthwork. When a construction site is small, steel lattice column support posts under intermediate trestle area support beams are intensive, the foundation pit has deep excavation, a vehicle ramp does not have enough horizontal length, an earthmoving vehicle can not go down to the pit bottom, and earthwork excavation construction is substantially difficult, excavation is carried out by heaping a soil island in the process of excavating a third layer and a fourth layer of the earthwork, a subgrade plate is inserted in both sides of center supports to retain earth, the soil island is heaped, the earthwork is excavated by way of the soil island by a long arm digging machine docked on a trestle. The method of the invention has the advantages of greatly improved excavation efficiency, shortened construction period, and obvious actual effect. The method is a preferred construction method of carrying out earthwork construction in an intensive support area of deep foundation pit steel lattice column.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Side-discharging construction method for subway station shared underground wall

InactiveCN101250883AReduce exposure timeExtension of timeArtificial islandsProtective foundationFloor slabSubway station

The invention relates to a side discharging construction method of a common diaphragm wall of a subway station, which comprises the following steps: V1ing, soil reinforcement: the soil reinforcement is done near the outer side of the common diaphragm wall of a subway station in a new underground structure foundation pit, thereby strengthening the stability of an enclosure protection system of a station. V2ing, reverse construction: the new structure of the outer side of the common diaphragm wall uses the reverse construction. Through using the reverse construction, a structure floor slab which is completed by the reverse construction is capable of forming an effective supporting function for the common diaphragm wall, thereby reducing the exposure time of the common diaphragm wall, fully using the time-space effect, increasing the unearthed efficiency, increasing the time of foundation pit excavation and the support construction time, and the support is done along with digging. The construction method of the invention is capable of effectively controlling the deformation of the side direction of the common diaphragm wall of the subway station after unloading.

Owner:SHANGHAI CONSTR NO 1 GRP

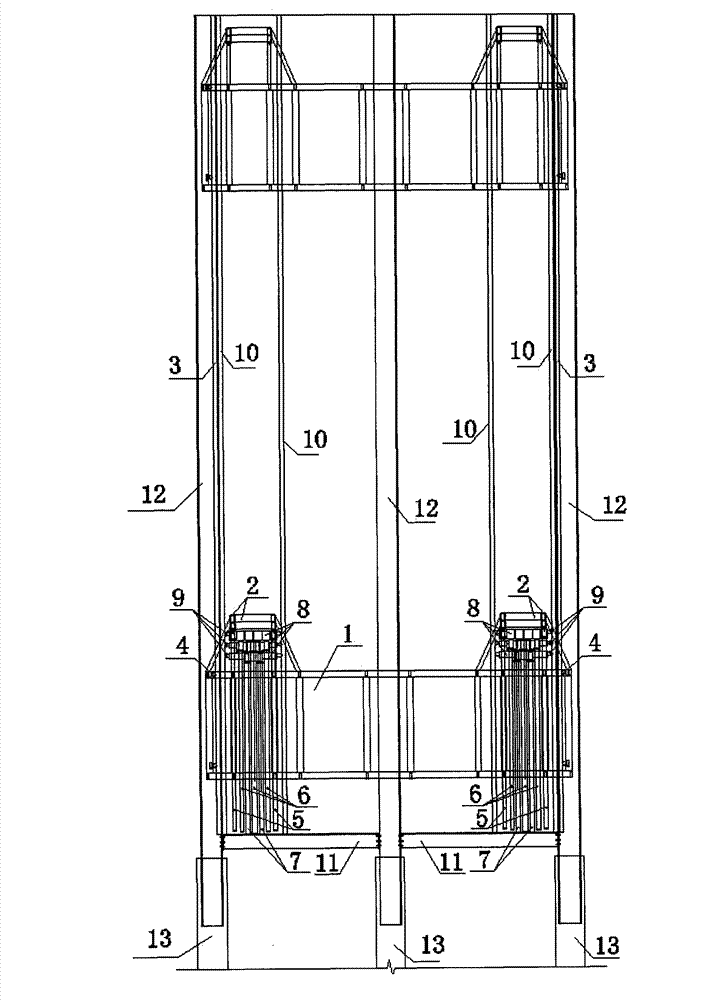

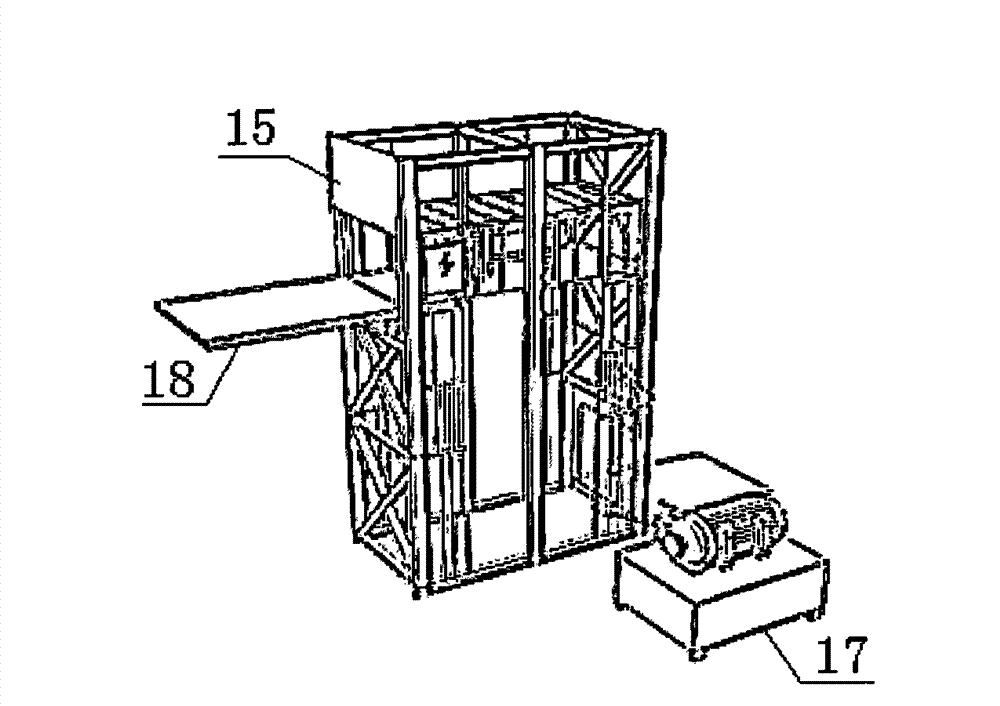

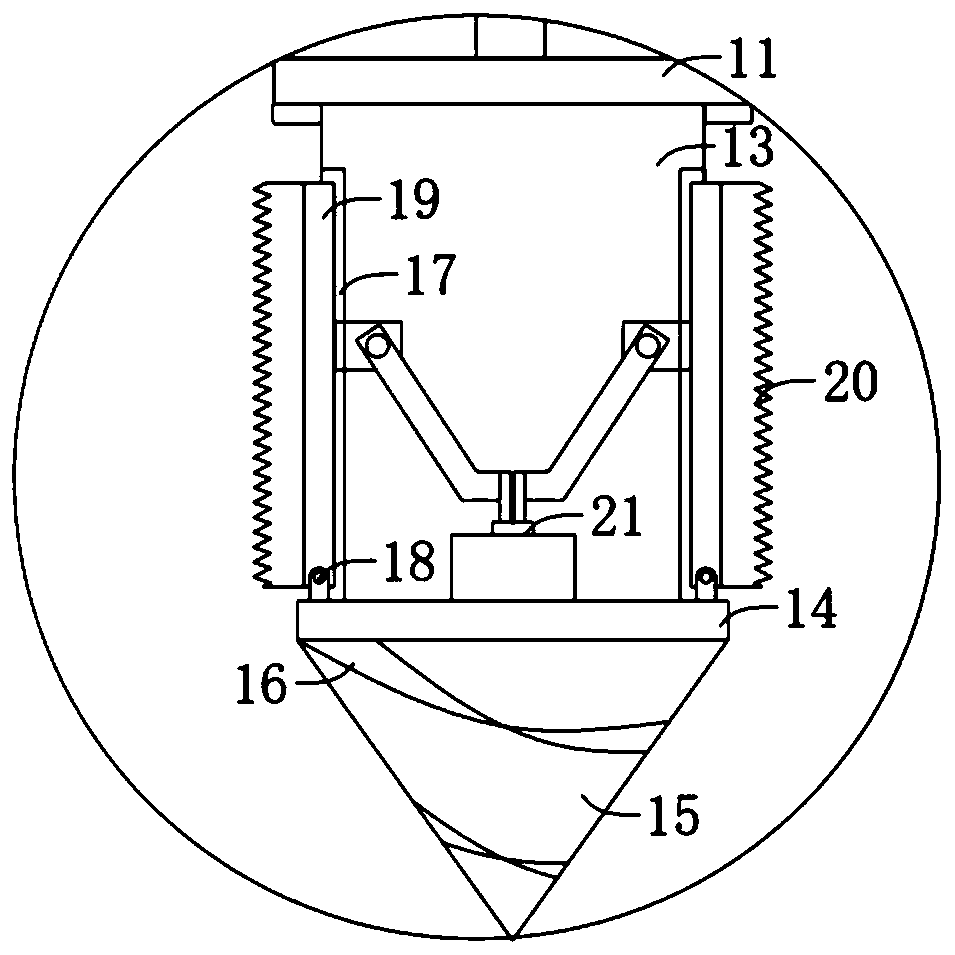

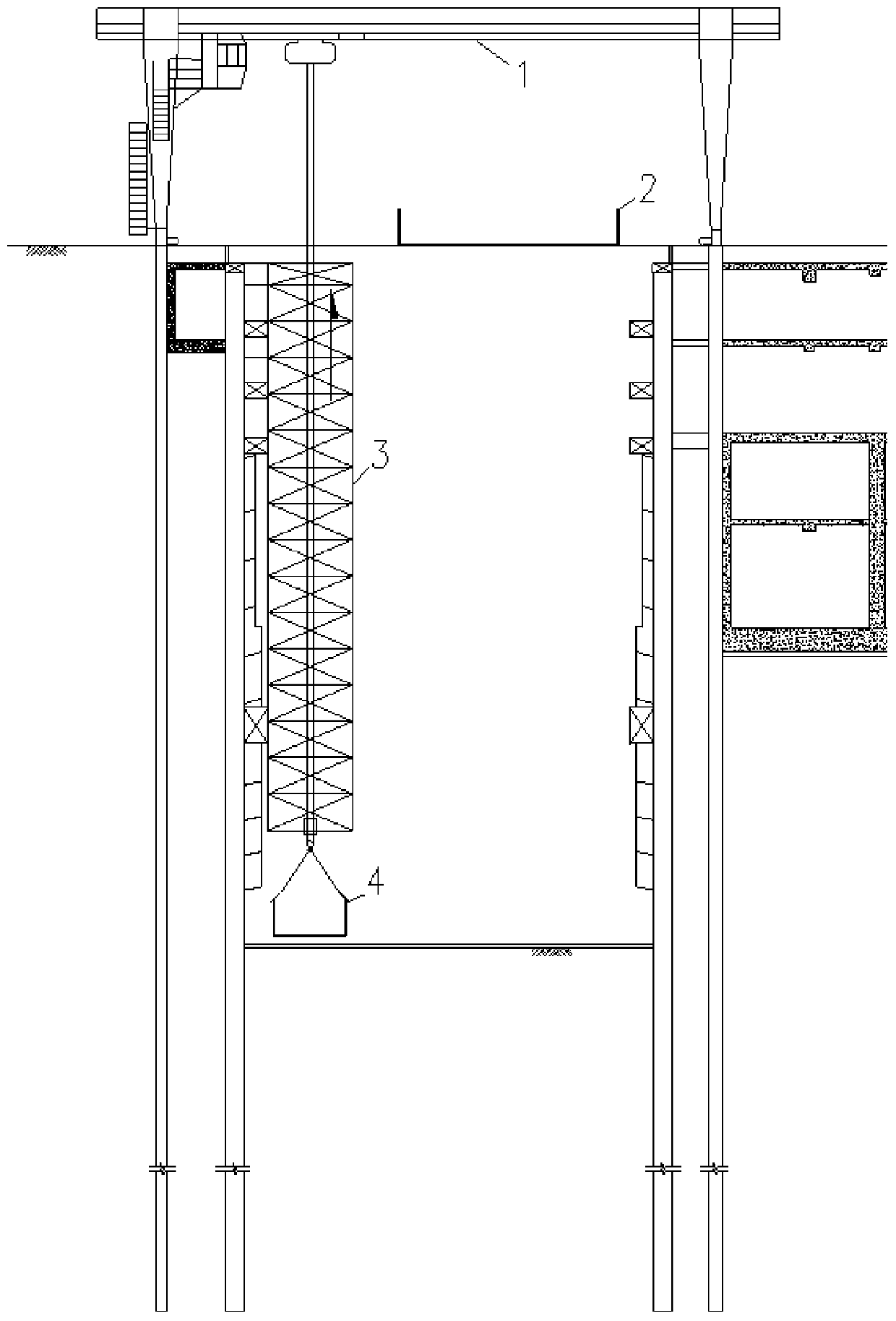

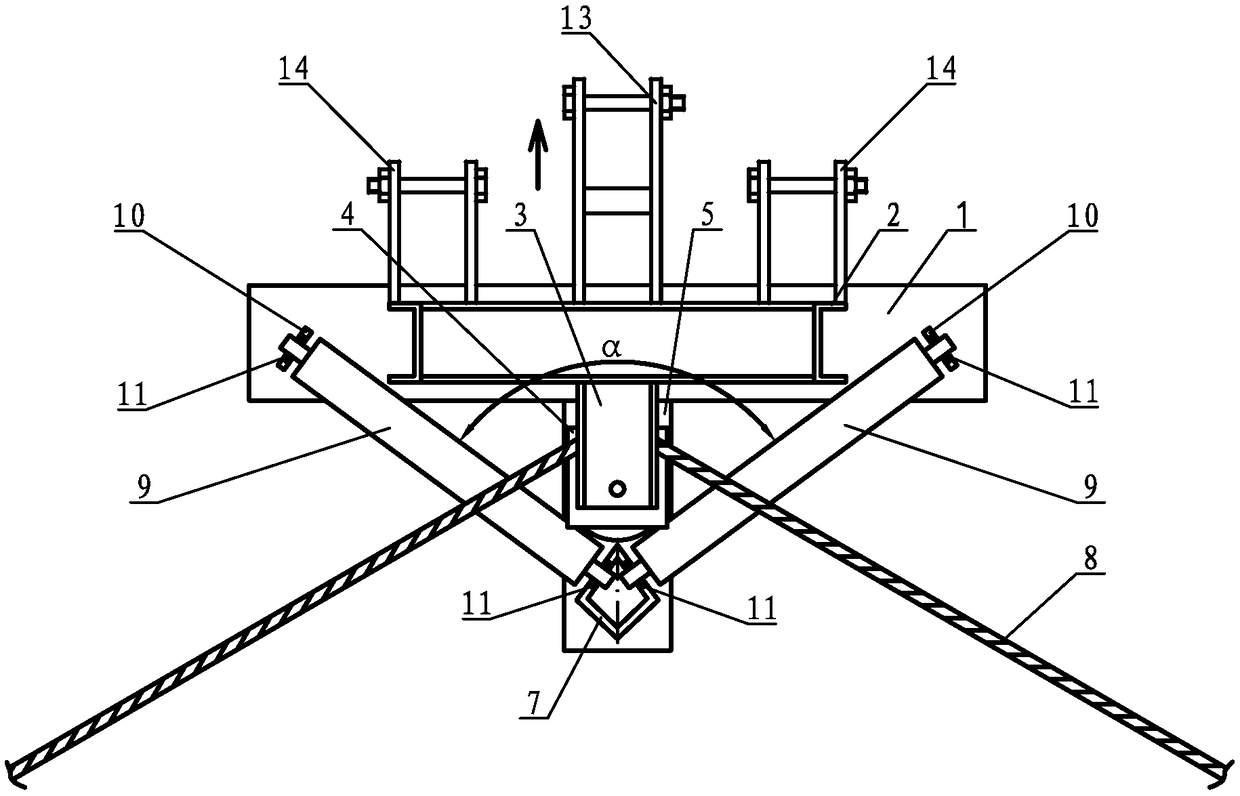

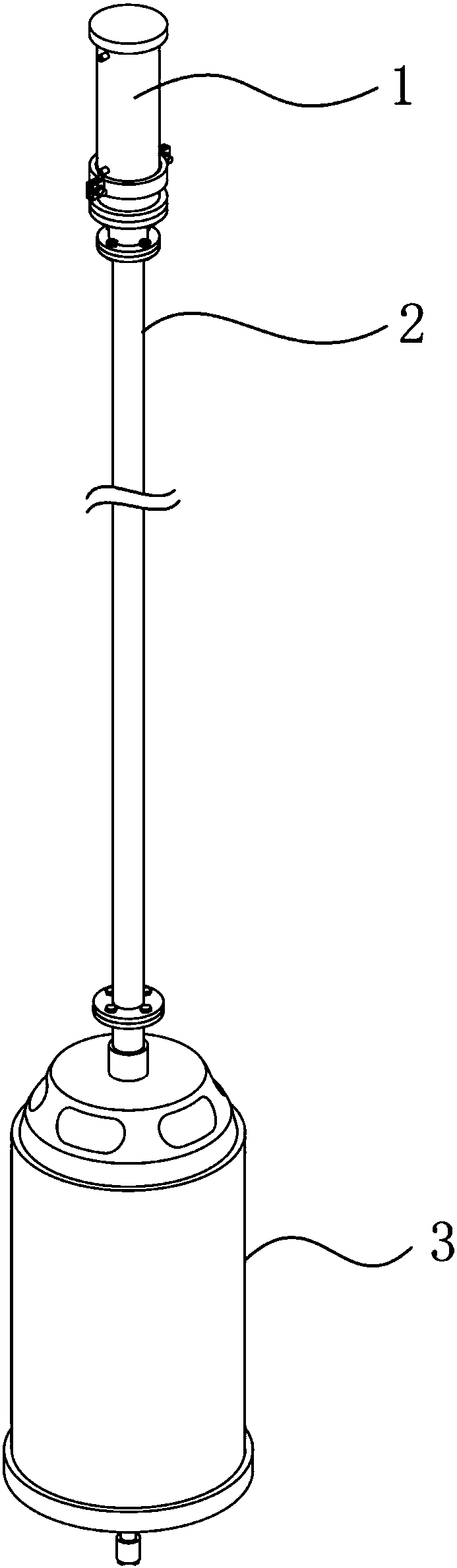

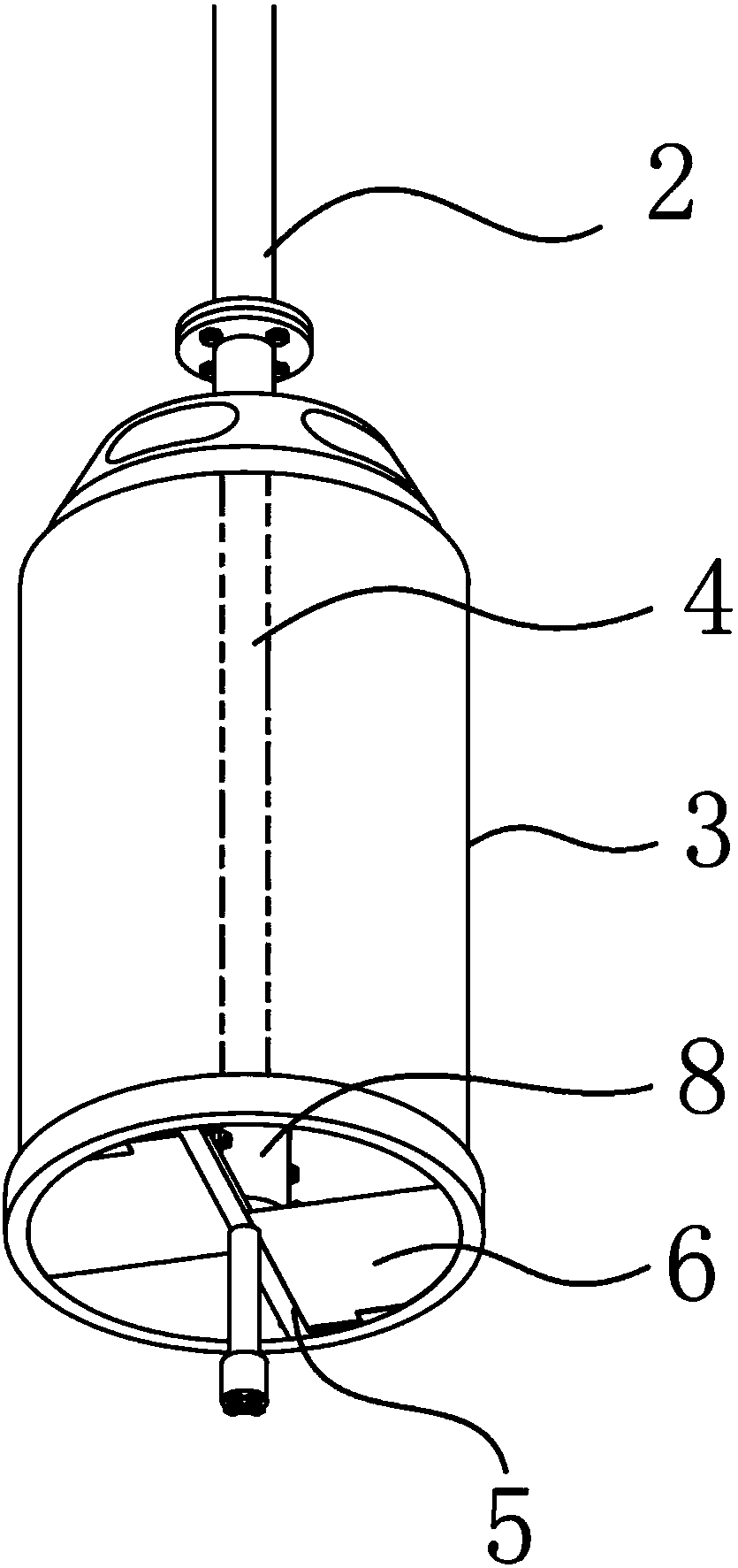

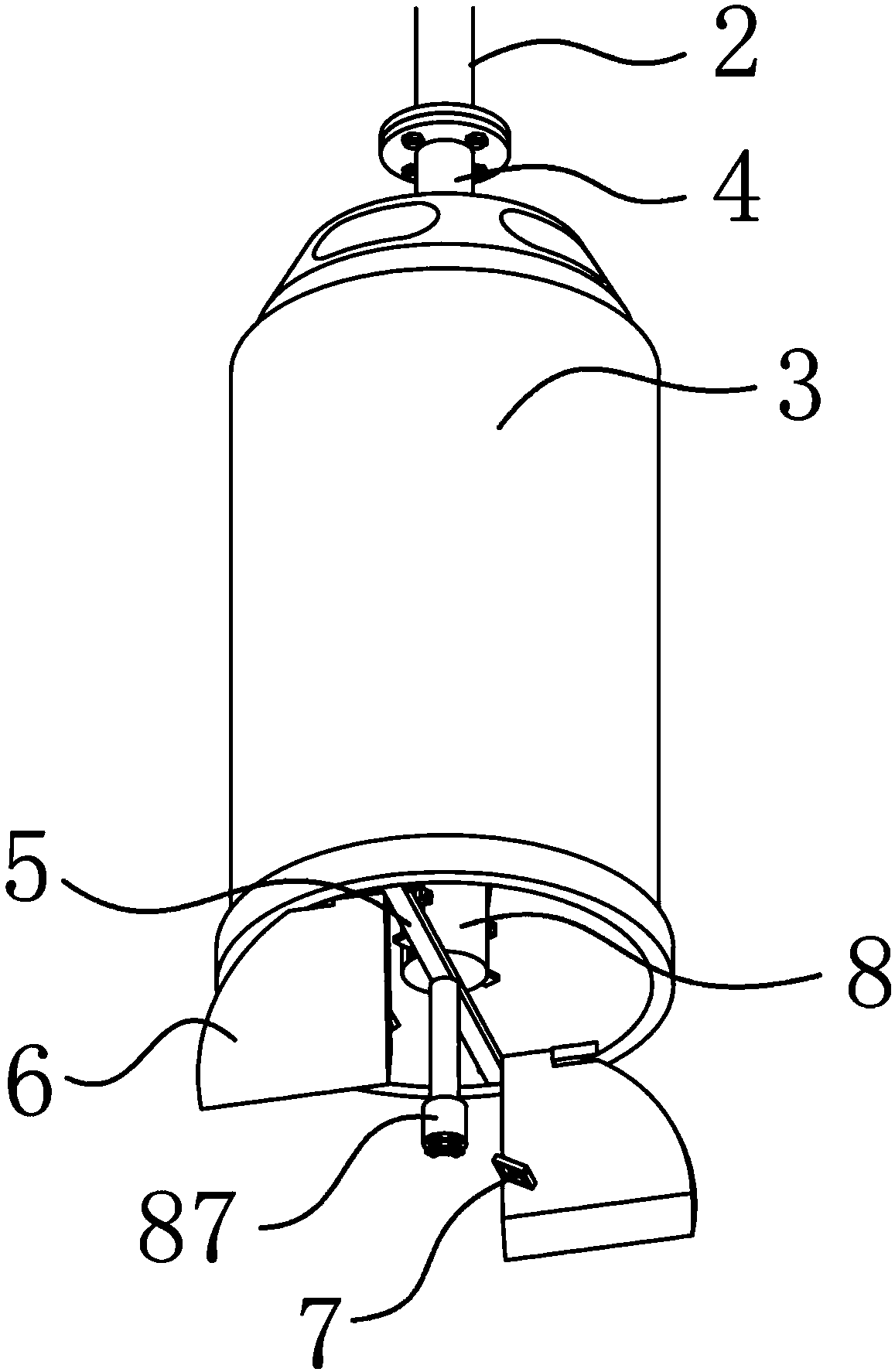

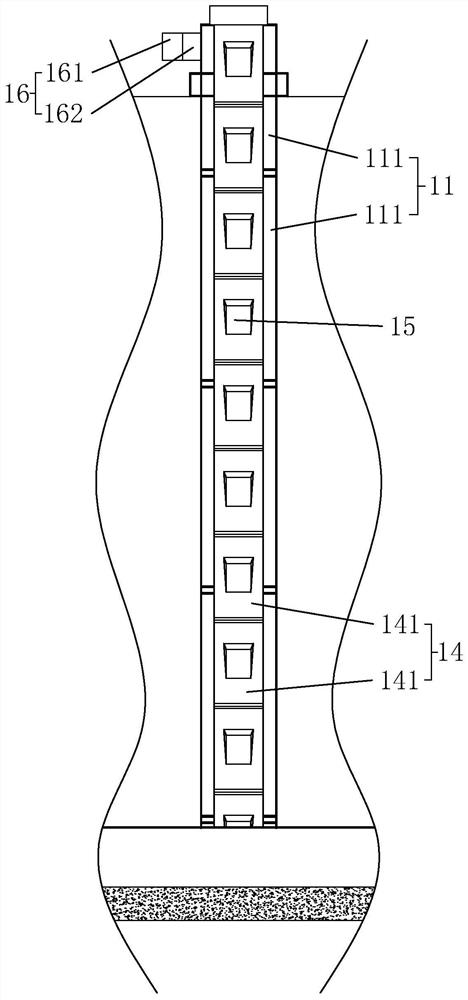

Large-scale lifting device based on deep foundation pit vertical earthmoving

ActiveCN102826430ASmall footprintQuick assembly and disassemblyElevatorsBuilding liftsHydraulic motorIntelligent control system

The invention discloses a large-scale lifting device based on deep foundation pit vertical earthmoving. The large-scale lifting device comprises a power system composed of an electric motor and a hydraulic motor, and is characterized by further comprising a cage system, an oil cylinder system, a support column system, a protective system and an intelligent control system, wherein the cage system is connected above the oil cylinder system and is driven by the same to be in vertical up-and-down movement, the oil cylinder system is positioned above the support column system, the protective system is arranged outside the cage system, and the intelligent control system is used for controlling linkage of the oil cylinder system with the protective system. The large-scale lifting device based on deep foundation pit vertical earthmoving can be used for deep foundation pits in various support forms, is small in occupied space, fast to mount and demount, capable of improving unearthing efficiency and shortening construction periods, reusable and cost-reducing.

Owner:中建三局集团(深圳)有限公司

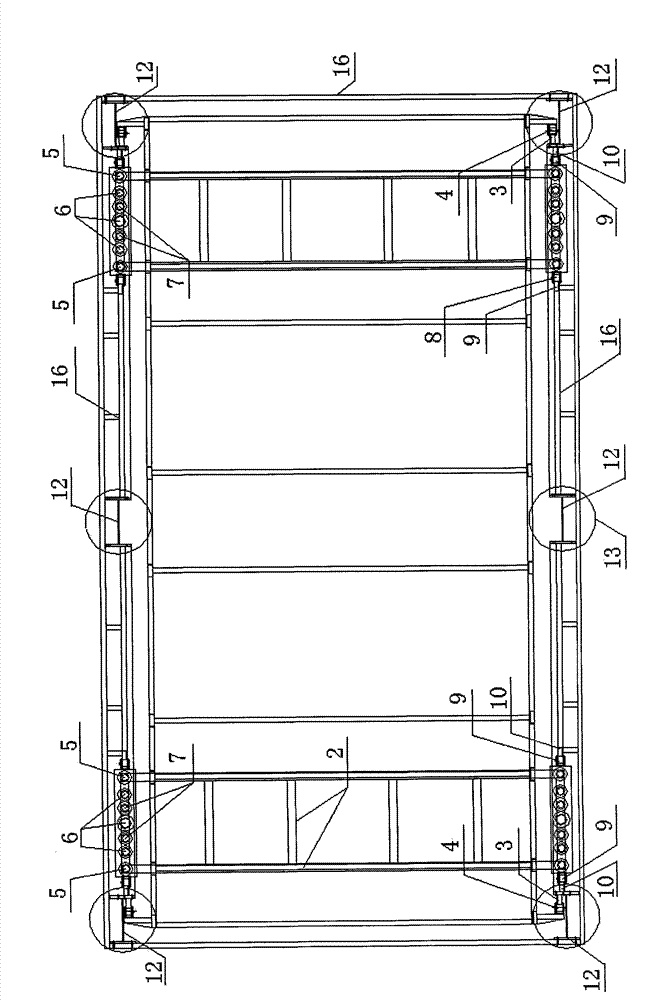

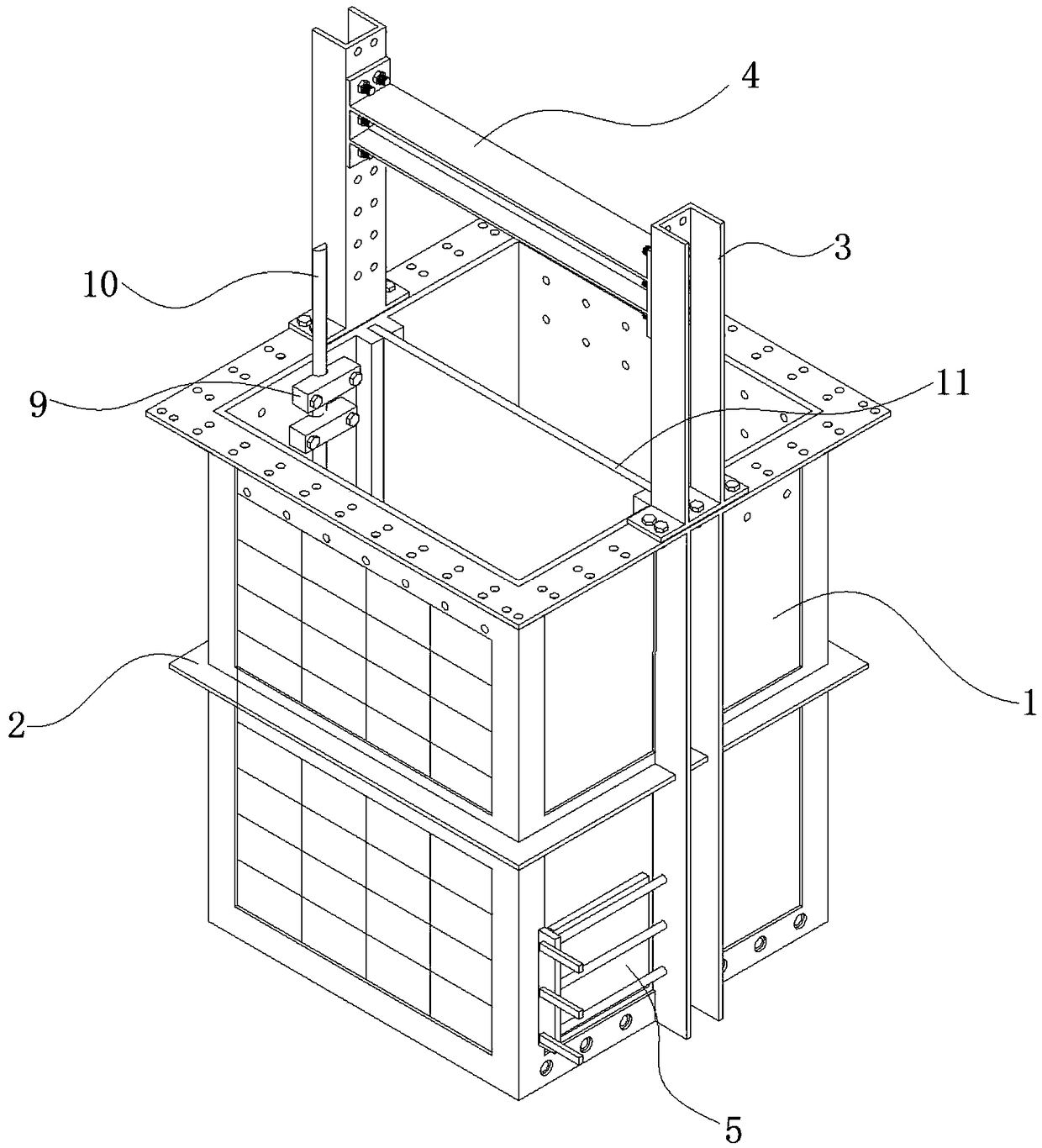

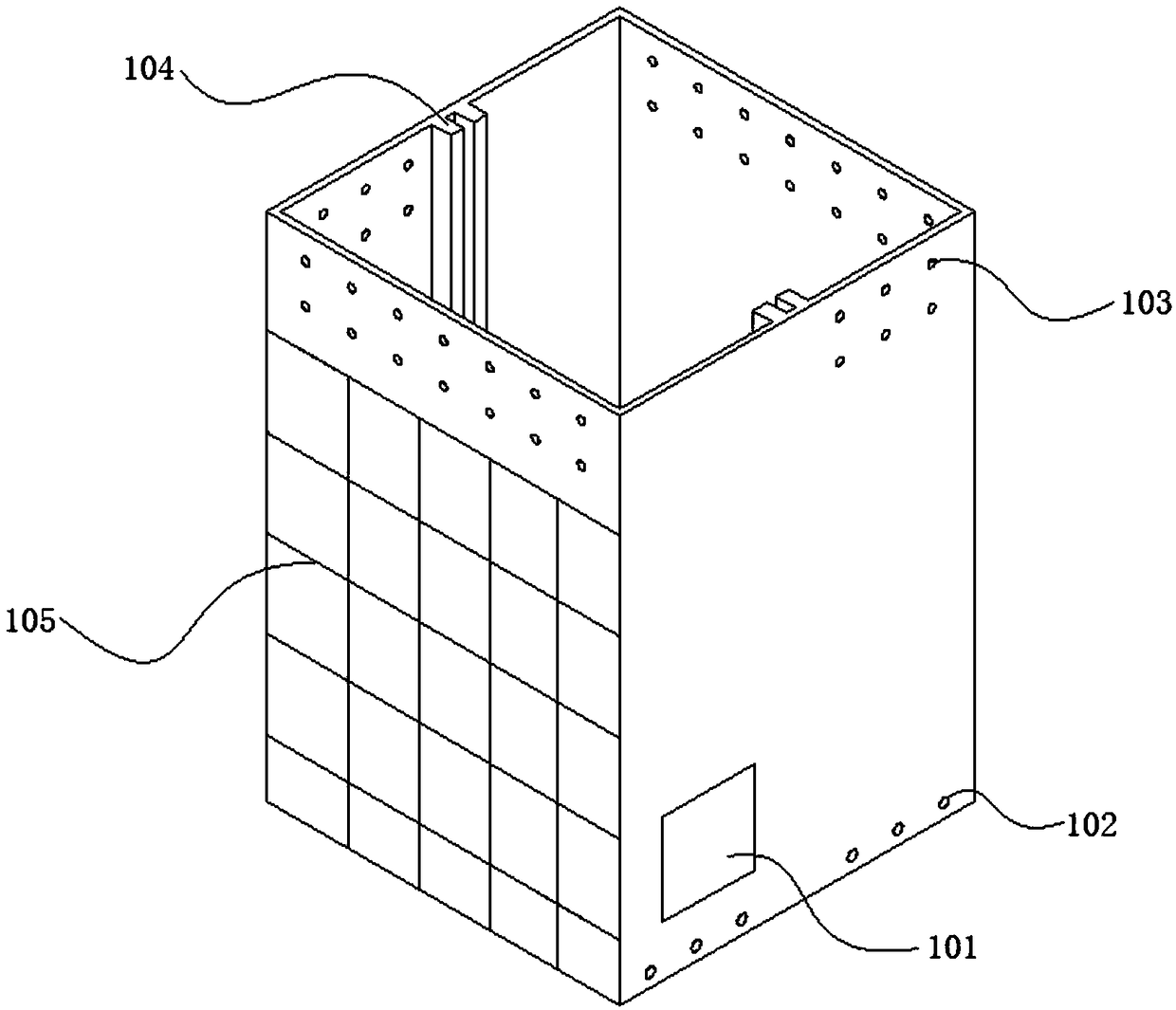

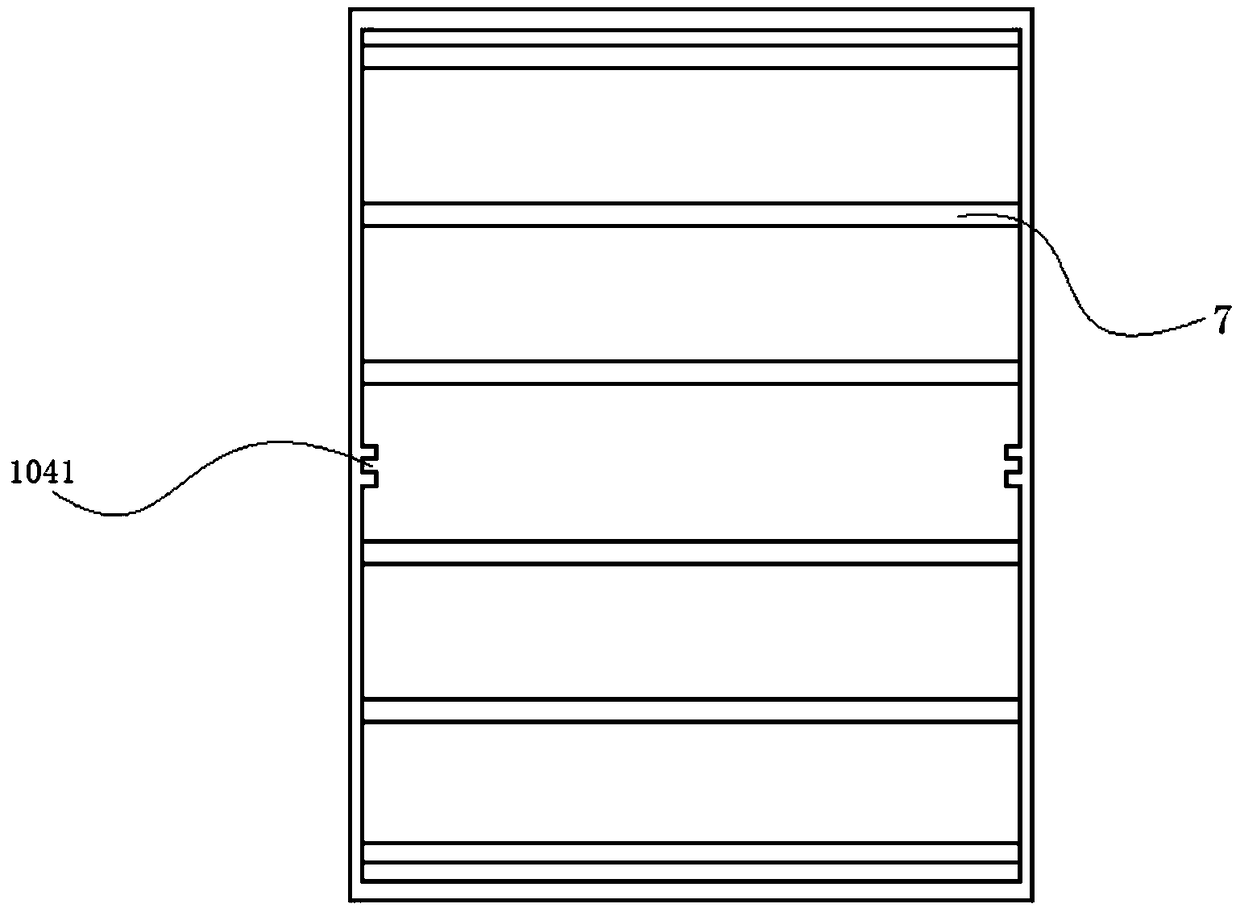

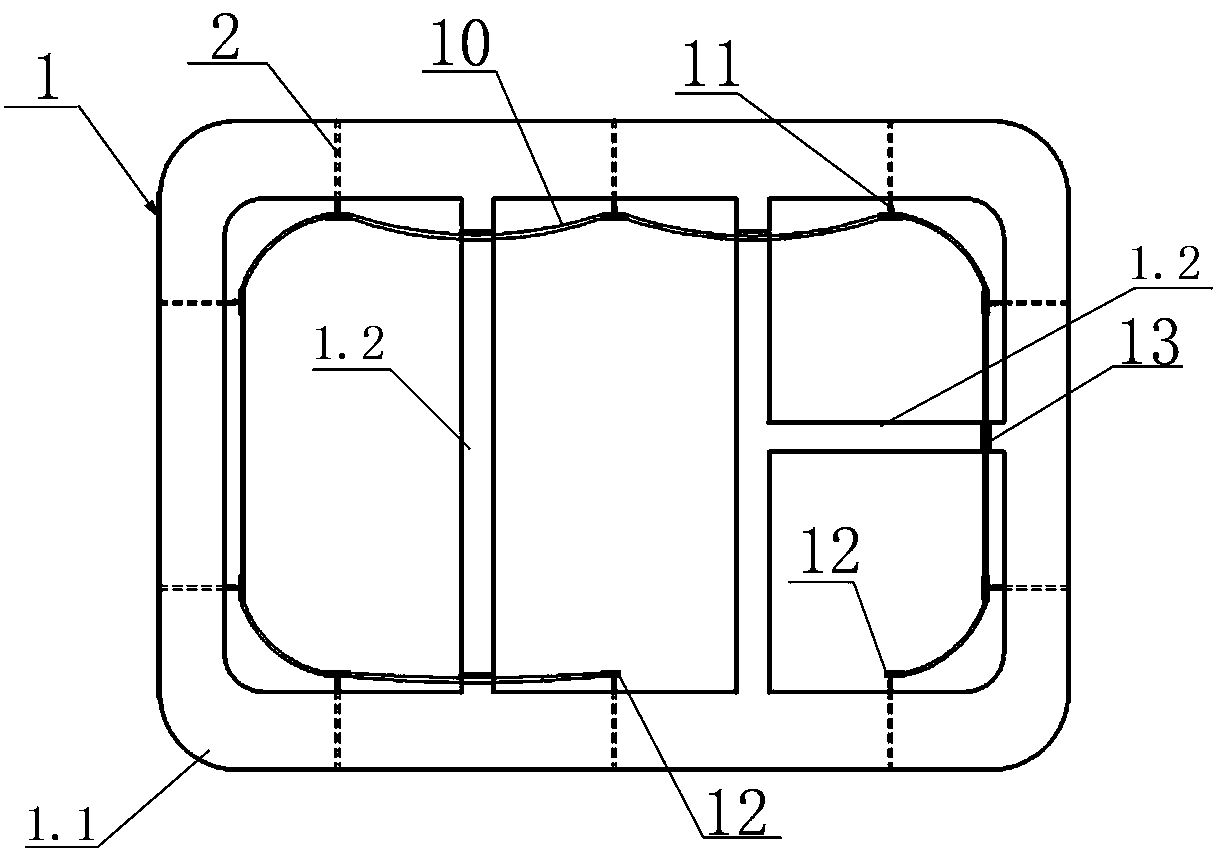

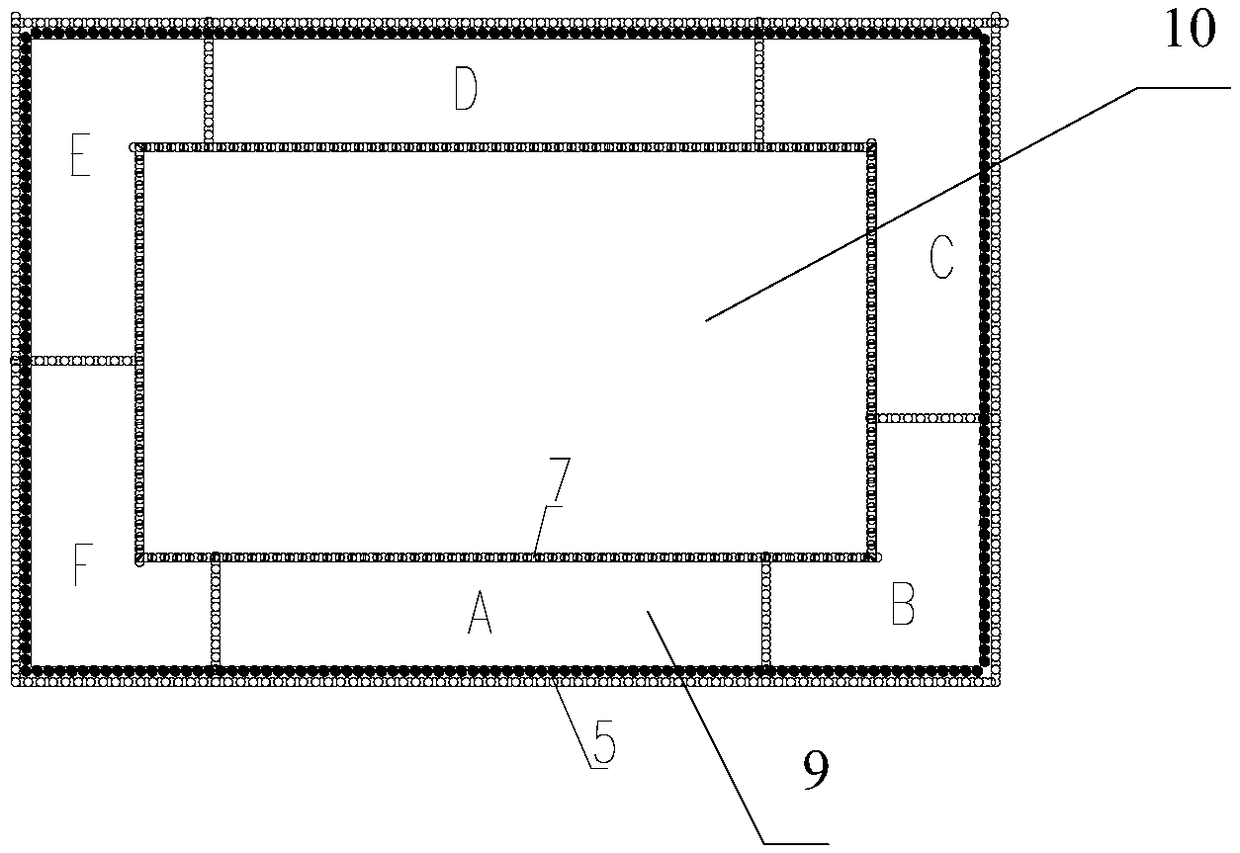

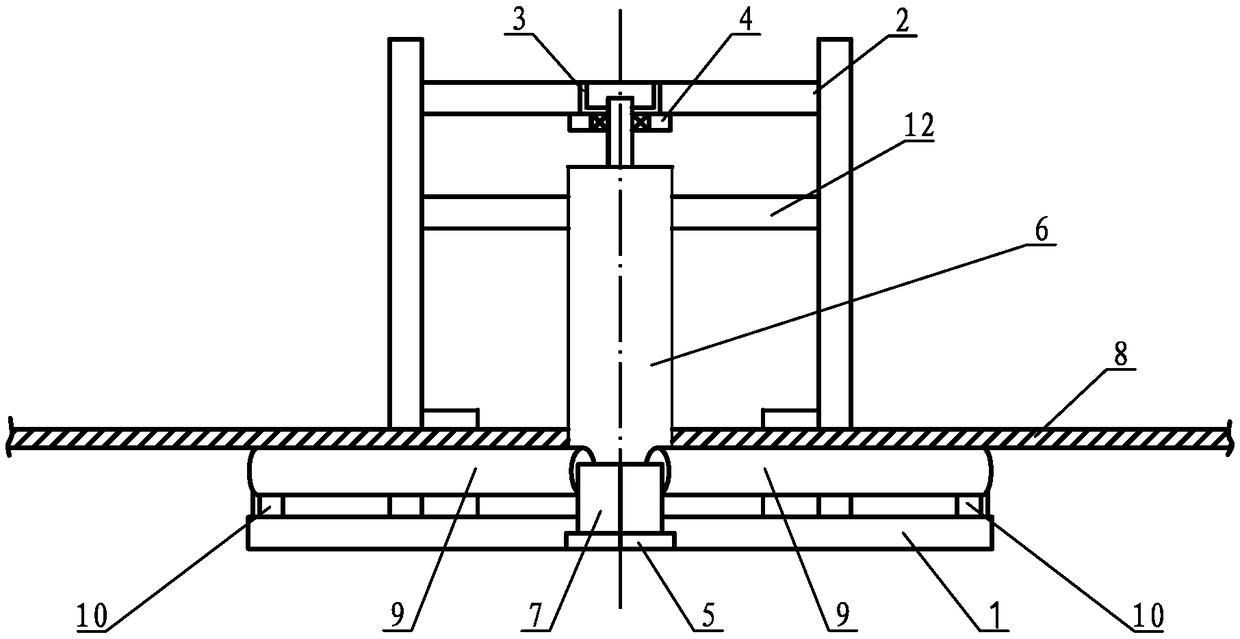

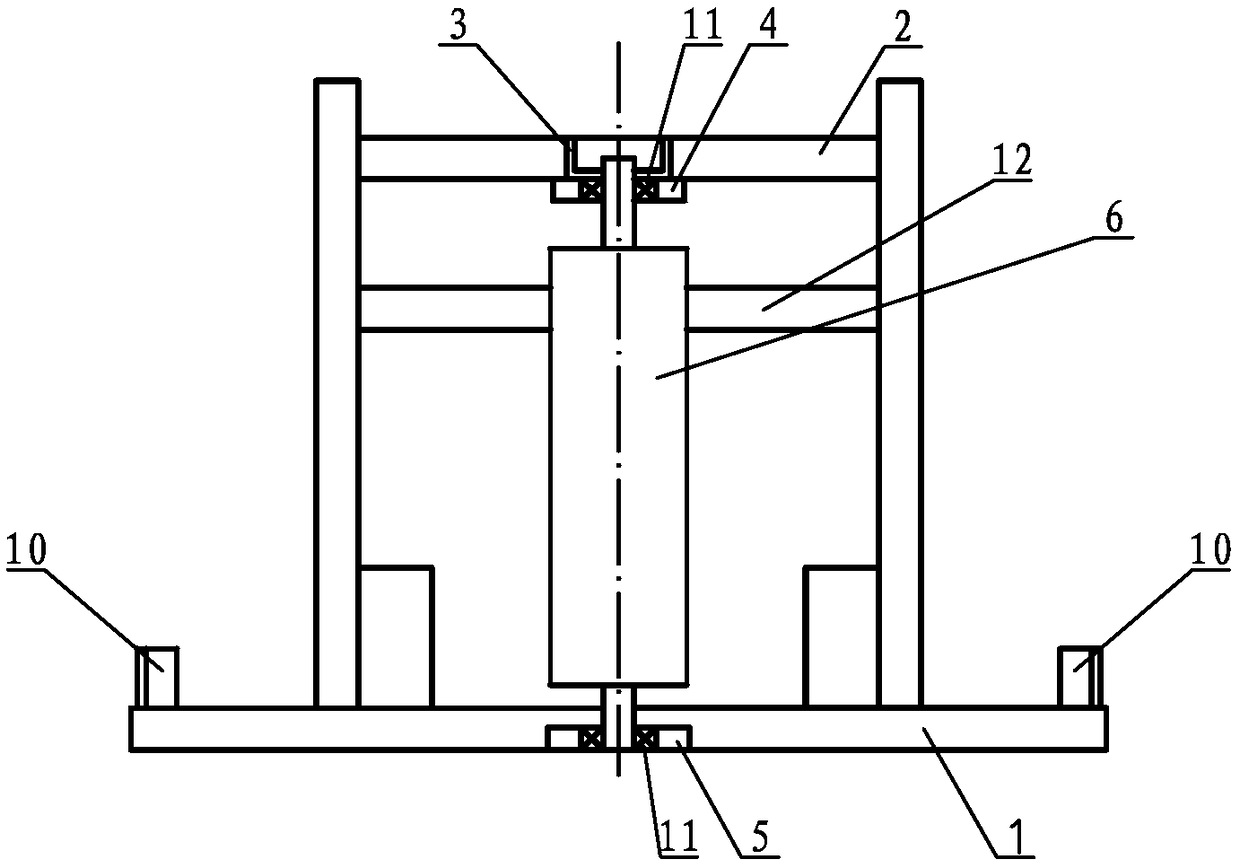

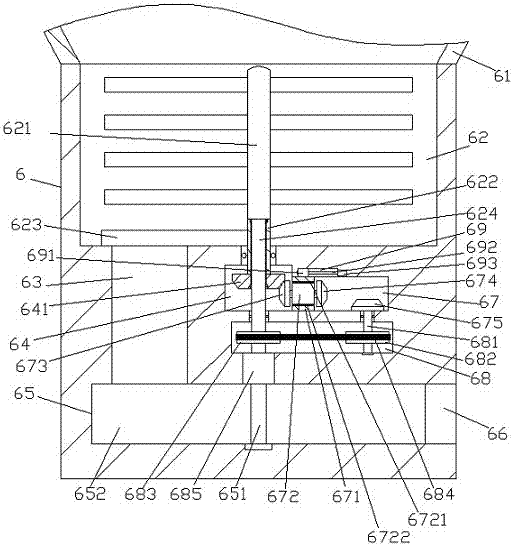

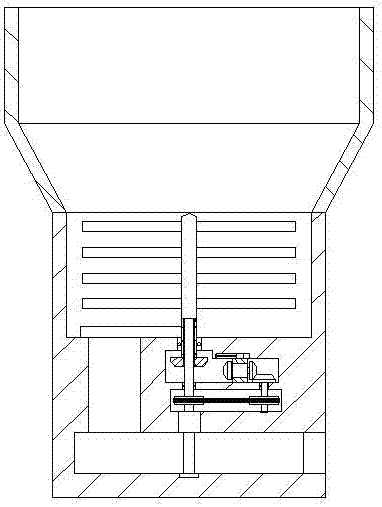

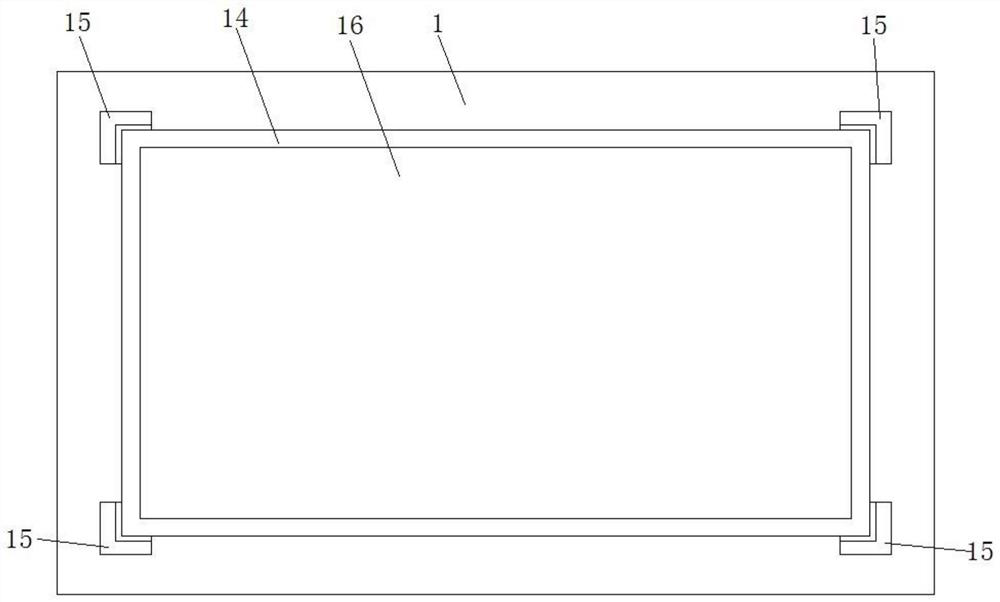

Multi-functional pile foundation model test box device and using method thereof

ActiveCN108951717AGood disassembly effectReduce weightFoundation testingMaterial strength using tensile/compressive forcesTest efficiencySheet steel

The invention provides a multi-functional pile foundation model test box device and a using method thereof. The test box device comprises an organic glass box body, a box body supporting steel frame,movable supporting seats and a movable counter force beam. The organic glass box body is put in the box body supporting steel frame, the lower portion of the box body supporting steel frame is provided with plug pin fixing holes so that a discharging door can be fixed, the movable supporting seats are arranged on an upper steel plate reinforcing hoop of the supporting steel frame, and the movablecounter force beam is arranged between the two movable supporting seats. The using method of the test box device comprises the steps of debugging preparation, sensor arrangement, pile burying, box interior position round column pile vertical loading, box wall semi-pile pile sinking soil squeezing testing and the like. The test box device is low in weight, good in part detachable performance, easyto carry and high in space availability, multiple working conditions can be simulated, and the test efficiency is improved.

Owner:CHONGQING UNIV

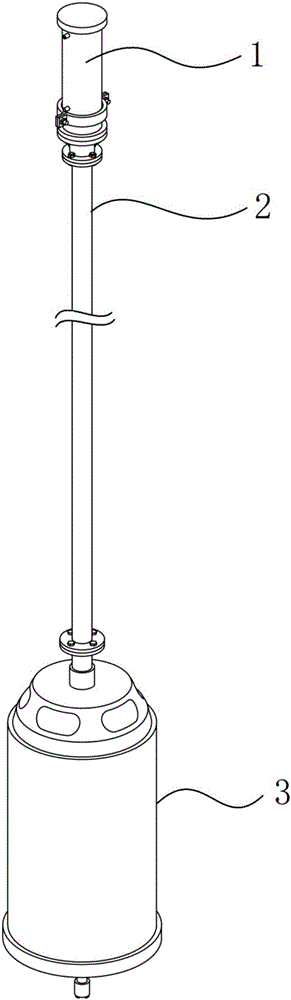

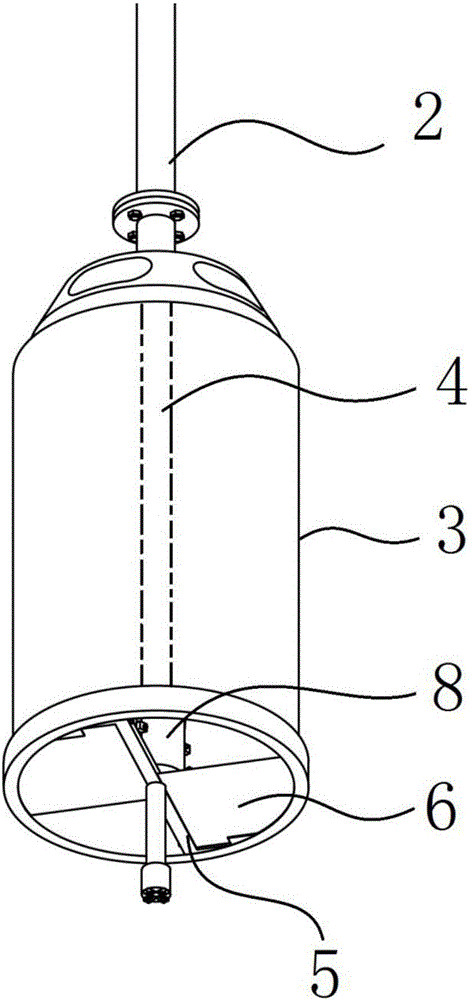

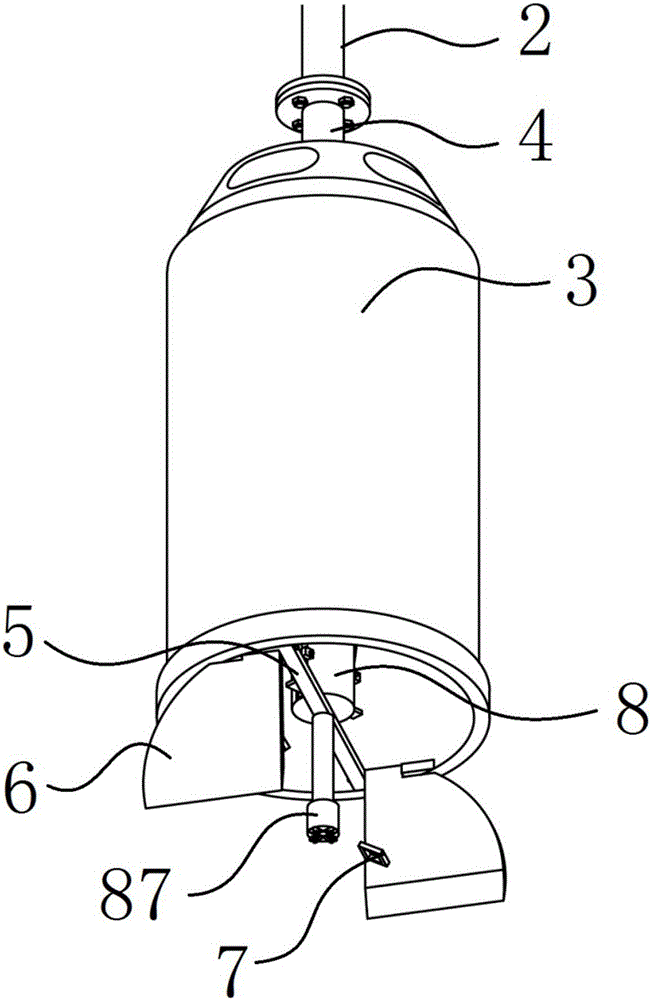

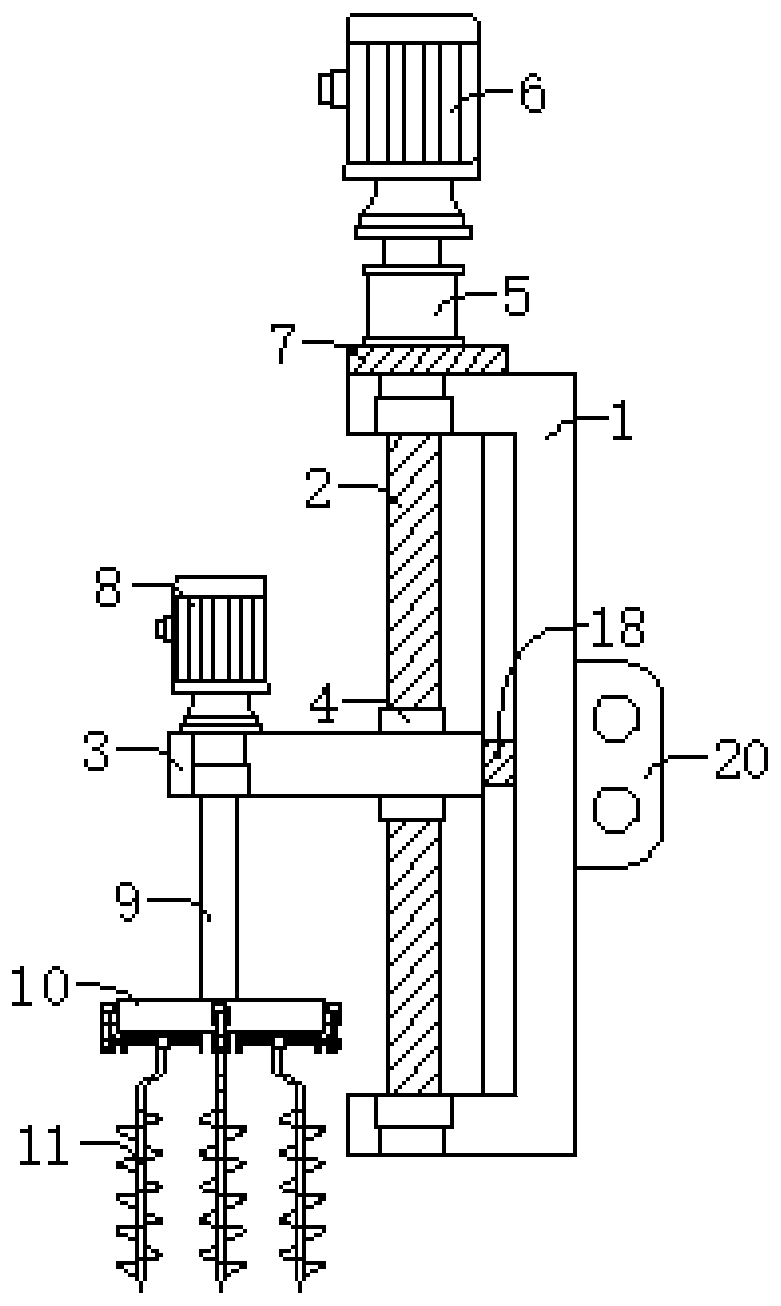

Drilling bucket type pile digging device

ActiveCN106089081AFix and stabilize the cylinder shellSimple and fast operationRotary drillingBorehole/well accessoriesGeotechnical engineeringDrill pipe

The invention relates to pile digging equipment, in particular to a drilling bucket type pile digging device. A rotating motor is connected with a vertically-downward rotating rod through an internally-arranged rotary oil cylinder, the lower end of the rotating rod is connected with a drilling bucket, a drill pipe which vertically penetrates through the drilling bucket is arranged in the drilling bucket, the upper end of the drill pipe is connected with the lower end of the rotating rod, the lower end of the drill pipe extends to the bottom of the drilling bucket, the lower end of the drill pipe is fixed to the inner wall of the drilling bucket through a fixing cross rod, the edge of the lower end of the inner wall of the drilling bucket is connected with two soil drilling blades in a hinged mode, the side edge of each soil drilling blade is provided with a clamping hole, and the lower end of the drill pipe is provided with a clamping control mechanism matched with the clamping holes. According to the drilling bucket type pile digging device, through scientific and reasonable structural connection, opening and closing of a drilling bucket opening can be easily and conveniently controlled through hydraulic control, therefore, the piling and soil digging efficiency is high, and the effect is good; in addition, the device can be controlled by a single person without needing cooperative work of many persons, the construction cost is reduced while the efficiency is improved, and a wide market prospect and the popularization significance are achieved.

Owner:李润

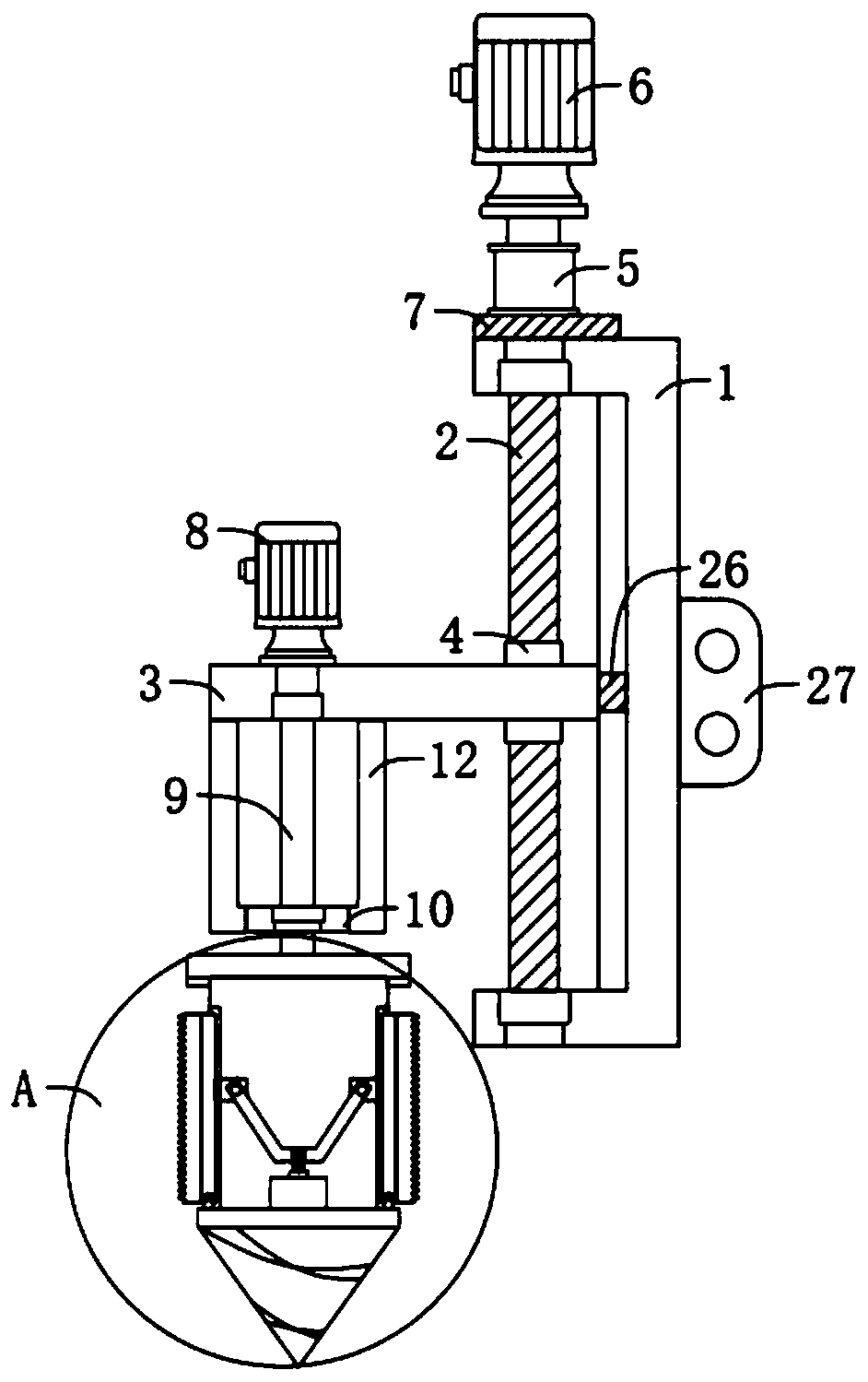

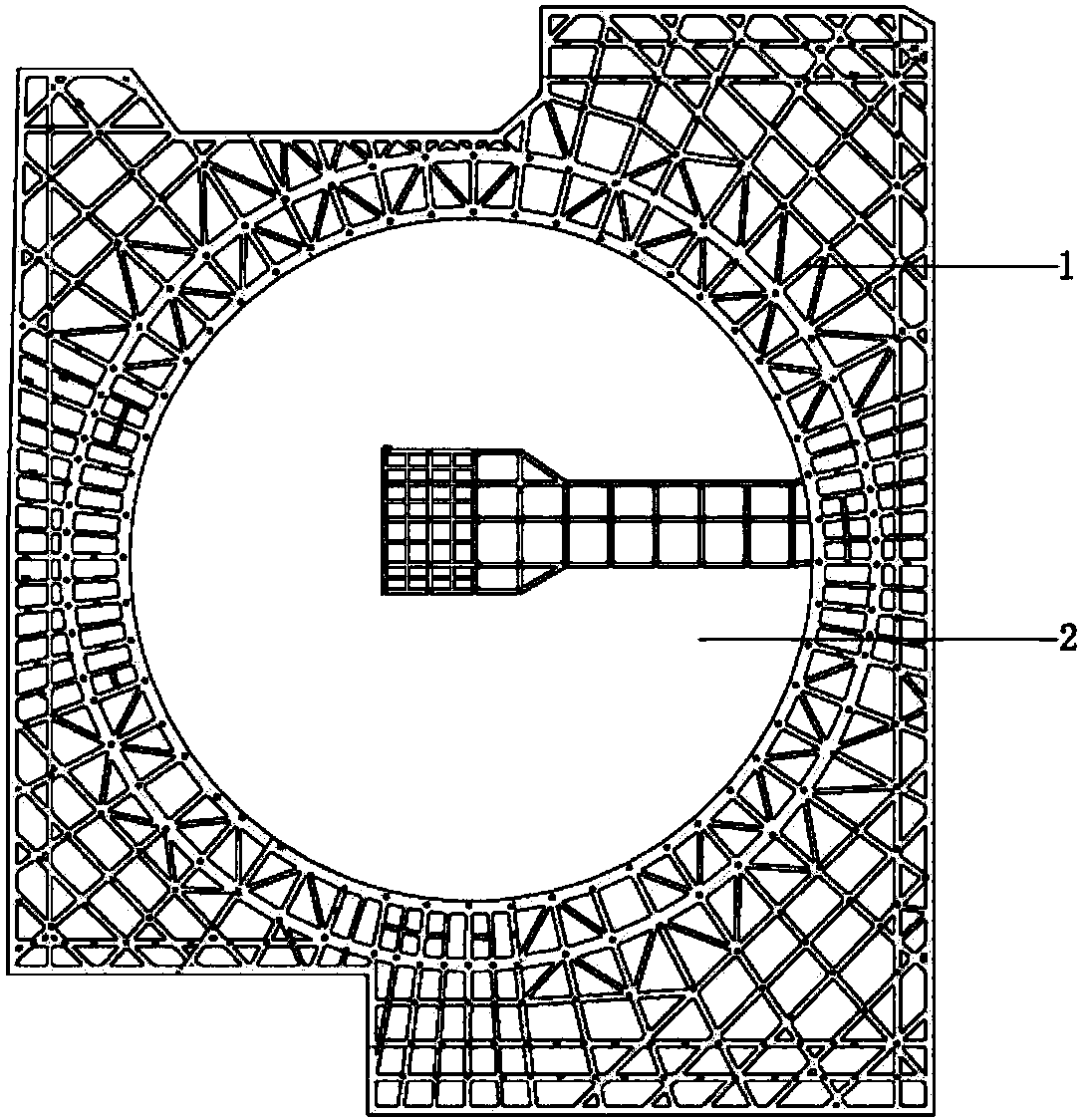

Variable-diameter drill bit device and hole digging device

The invention discloses a variable-diameter drill bit device. The variable-diameter drill bit device comprises a support, a conical base, a linear driving element and multiple hole digging tool modules, the support comprises a bottom cover, the bottom face of the conical base is arranged on the bottom face of the bottom cover, the bottom face of a linear driving element body is arranged on the topface of the bottom cover, the motion direction of the output end of the linear driving element is the vertical direction, each hole digging tool module in the hole digging tool modules comprises a hole digging tool, a tool frame and a push rod, one ends of the push rods are hinged to the inner sides of the tool frames, the other ends of the push rods are hinged to the output end of the linear driving element, the bottom of the tool frames are hinged to the bottom cover, and the hole digging tools are arranged on the outer sides of the tool frames. The variable-diameter drill bit device has the advantages of being high in mucking earth rate, variable in diameter and the like, and has the good practicability, and in addition, the invention further provides a hole digging device.

Owner:GUIGANG POWER SUPPLY BUREAU OF GUANGXI POWER GRID CO LTD

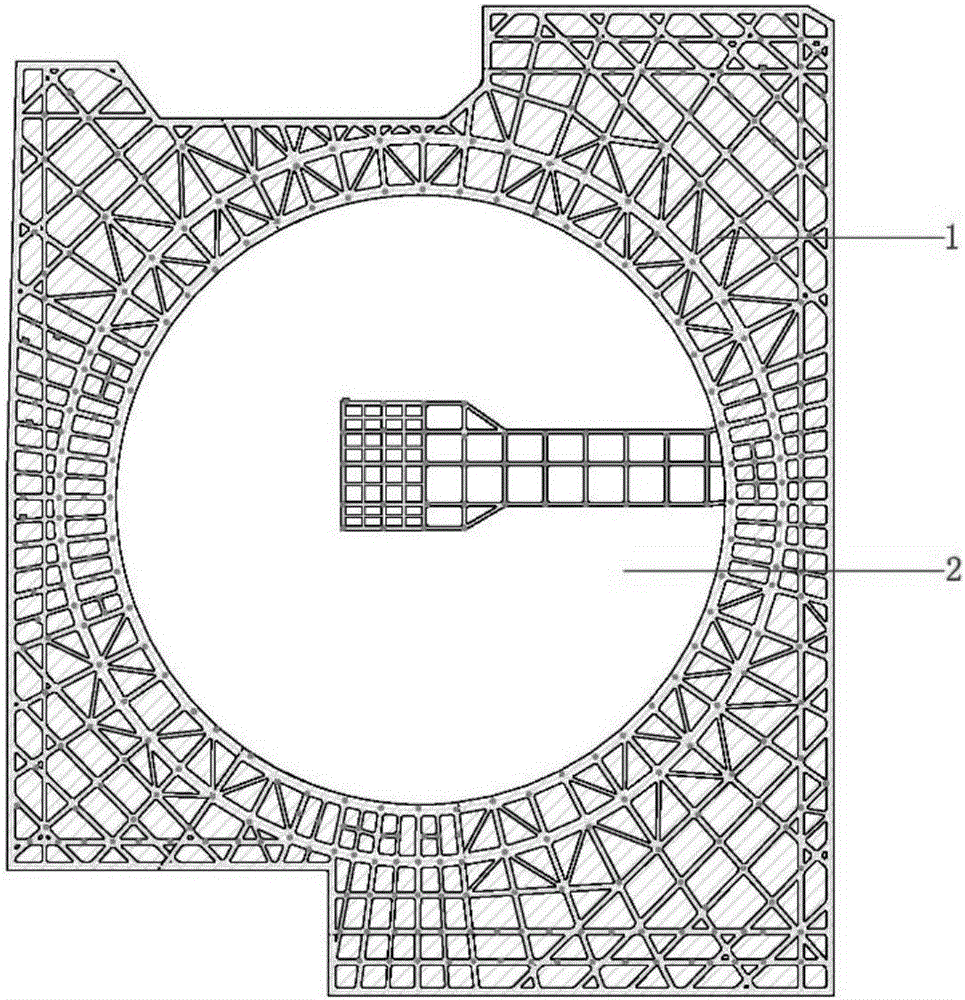

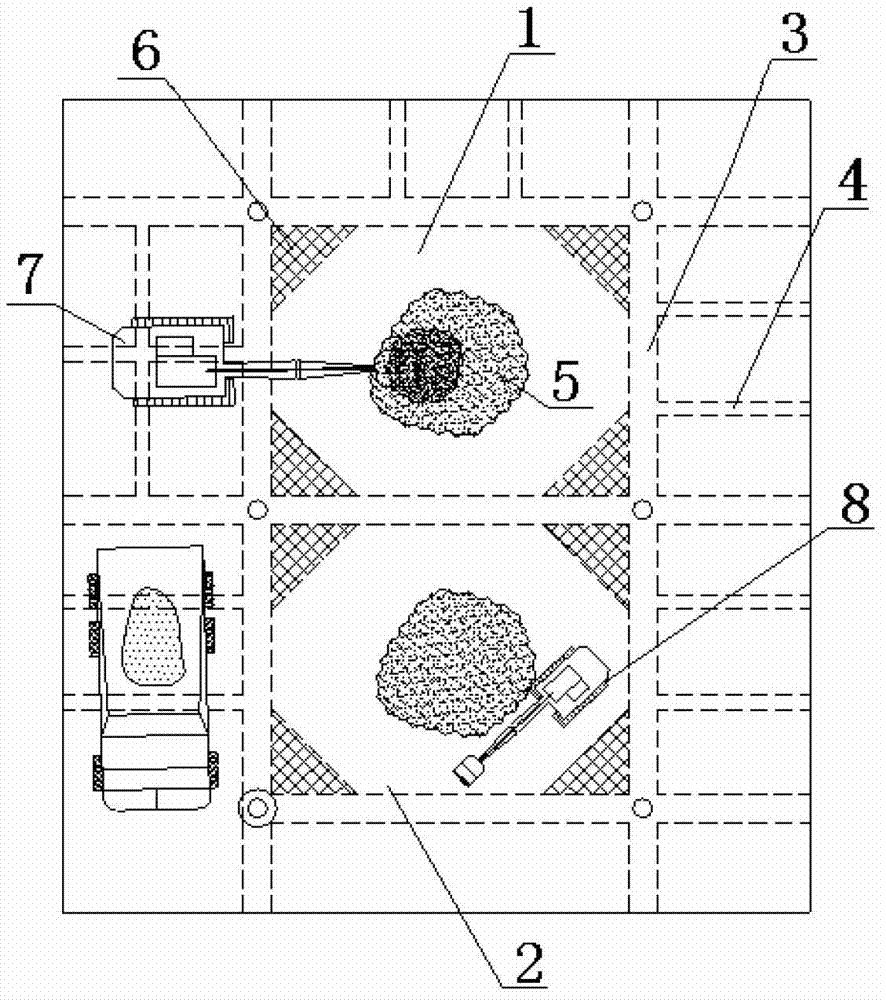

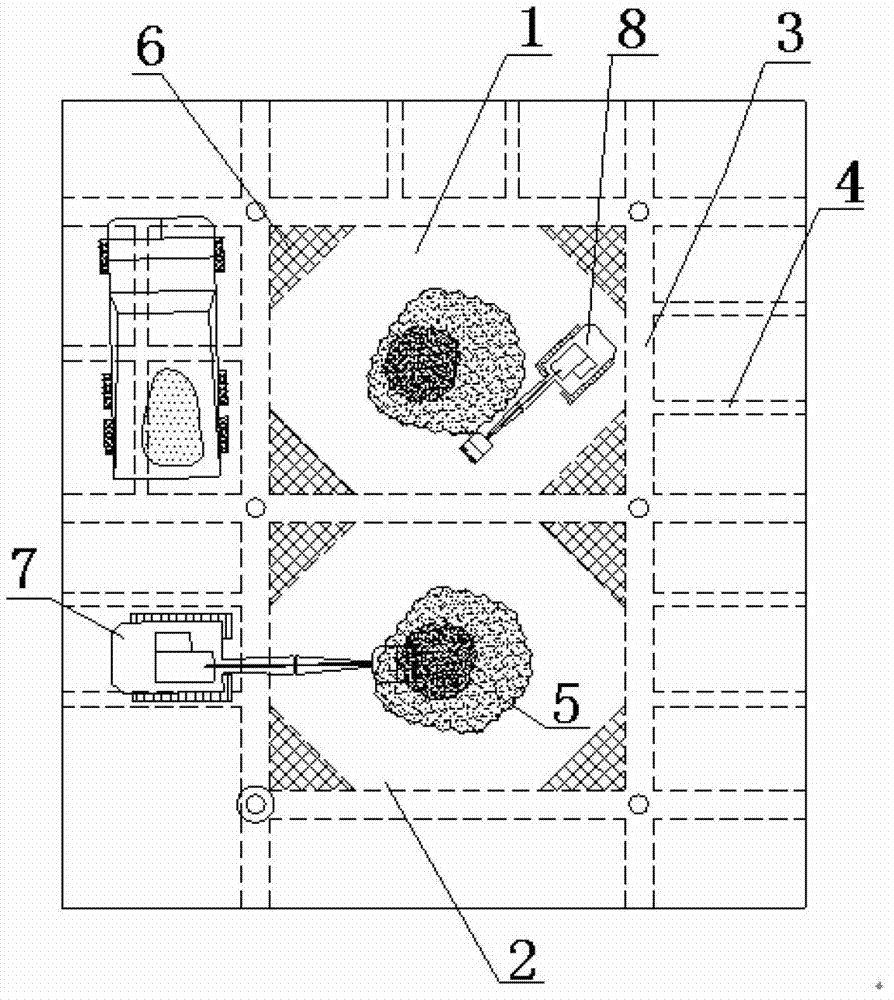

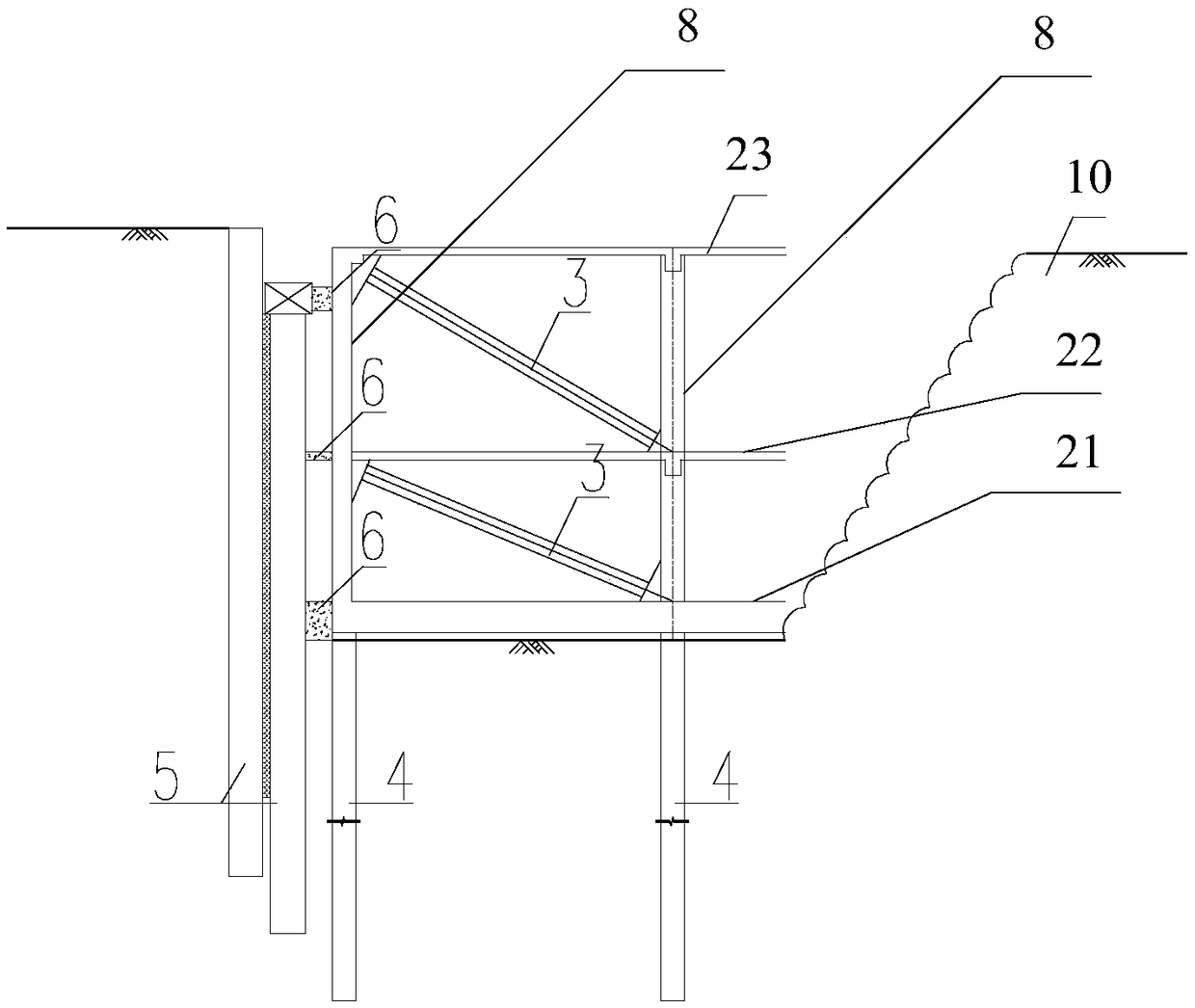

Combined supporting system for foundation pit central island basin type excavation and construction method thereof

The invention provides a combined supporting system for a foundation pit central island basin type excavation and a construction method thereof. A grid type double-shaft cement-soil mixing pile gravity type enclosure wall is added to replace a soil body to slope, steel inclined struts are arranged after overall pouring of a tower bottom plate is completed, and follow-up construction work is carried out. The double-shaft cement-soil mixing pile gravity type enclosure wall is used for replacing the soil body slope, so that the length of the steel inclined struts can be properly shortened, and the influence of the steel inclined struts on foundation pit deformation is reduced; a foundation bottom plate of a tower extends to the position, close to the edge side of a foundation pit, of part ofa foundation bottom plate of a basement to be constructed, the problem of tower bottom plate cutting caused by central island basin type earth excavation is solved, the foundation bottom plate of thetower can be integrally poured, integrity and continuity of the tower structure are guaranteed, and other quality problems such as water leakage caused by improper later construction joint treatment are avoided.

Owner:SHANGHAI CONSTRUCTION GROUP

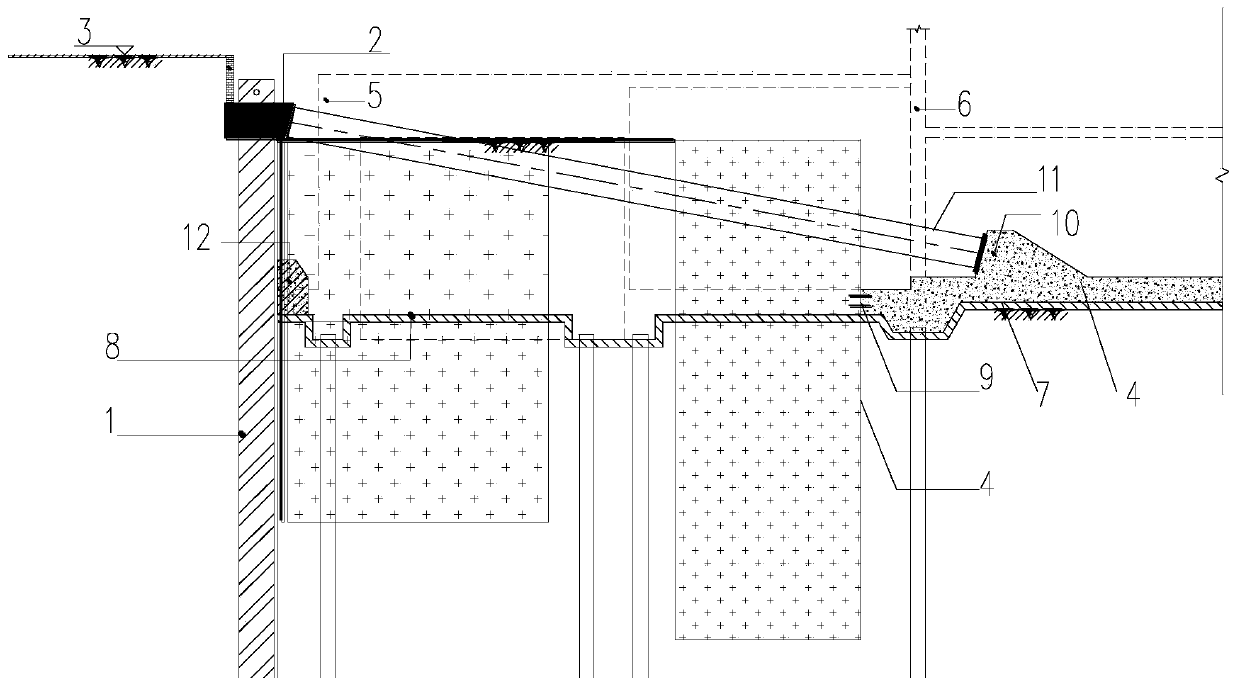

Annular deep foundation pit excavation construction method

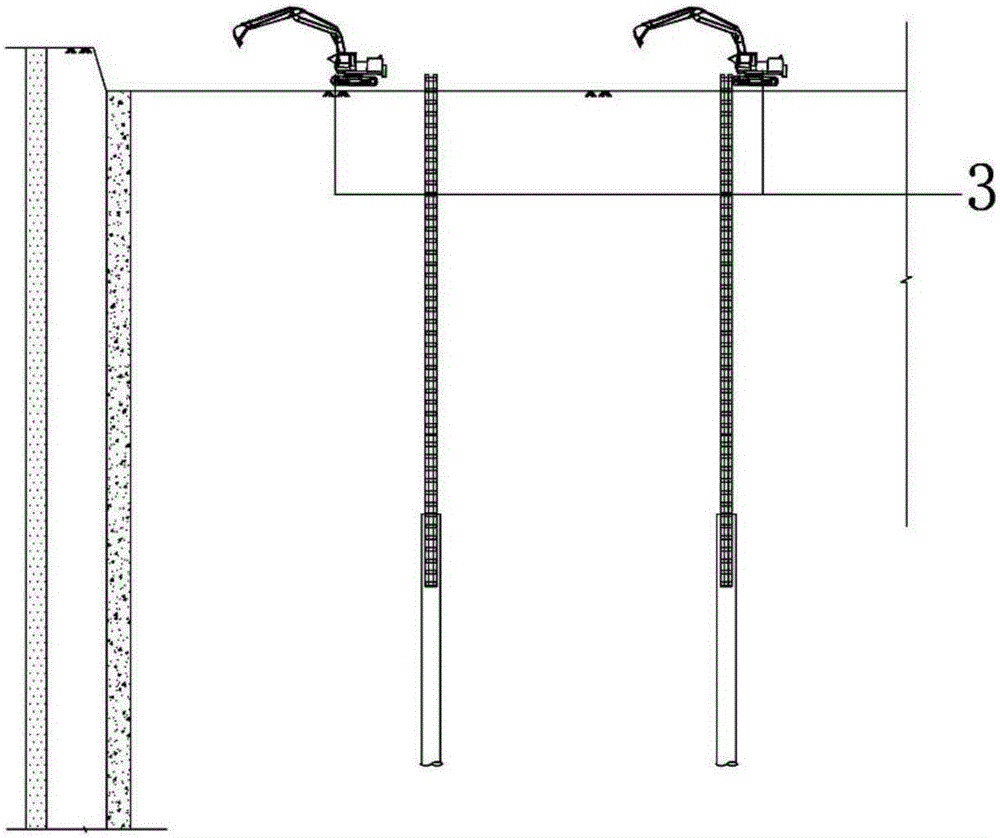

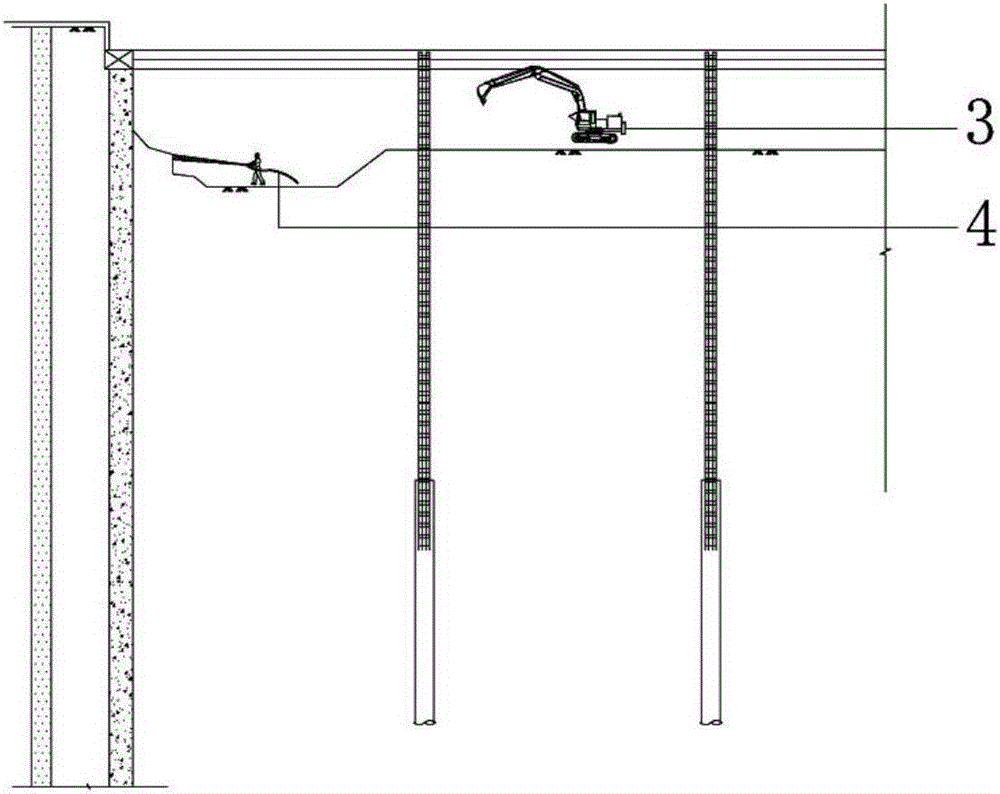

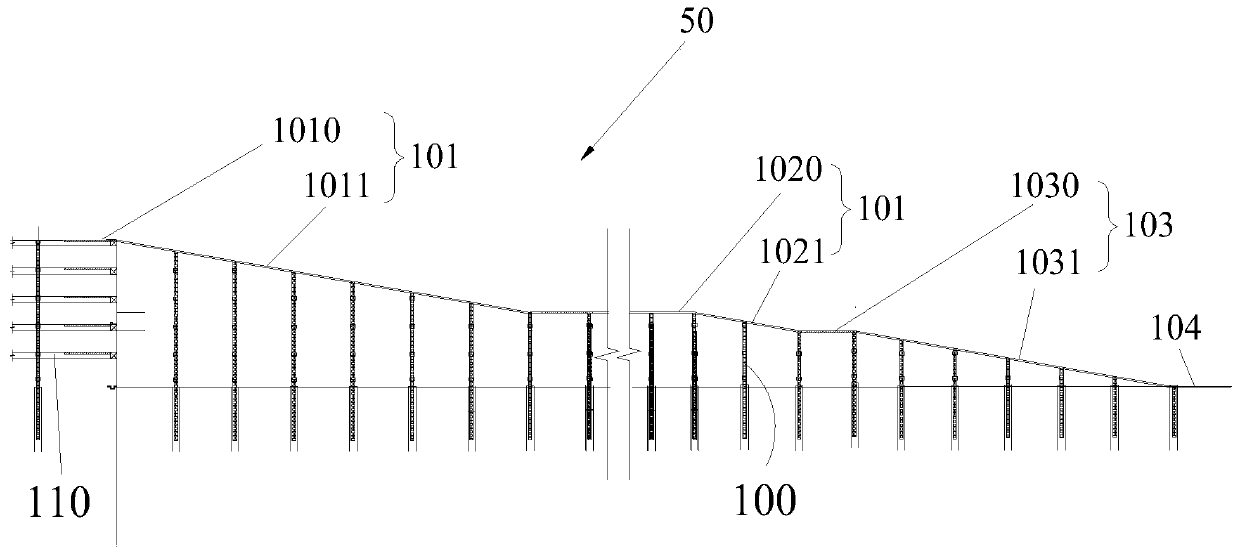

PendingCN110206034AAffect stabilityShorten the lengthExcavationsBridge materialsStructural engineeringBuilding construction

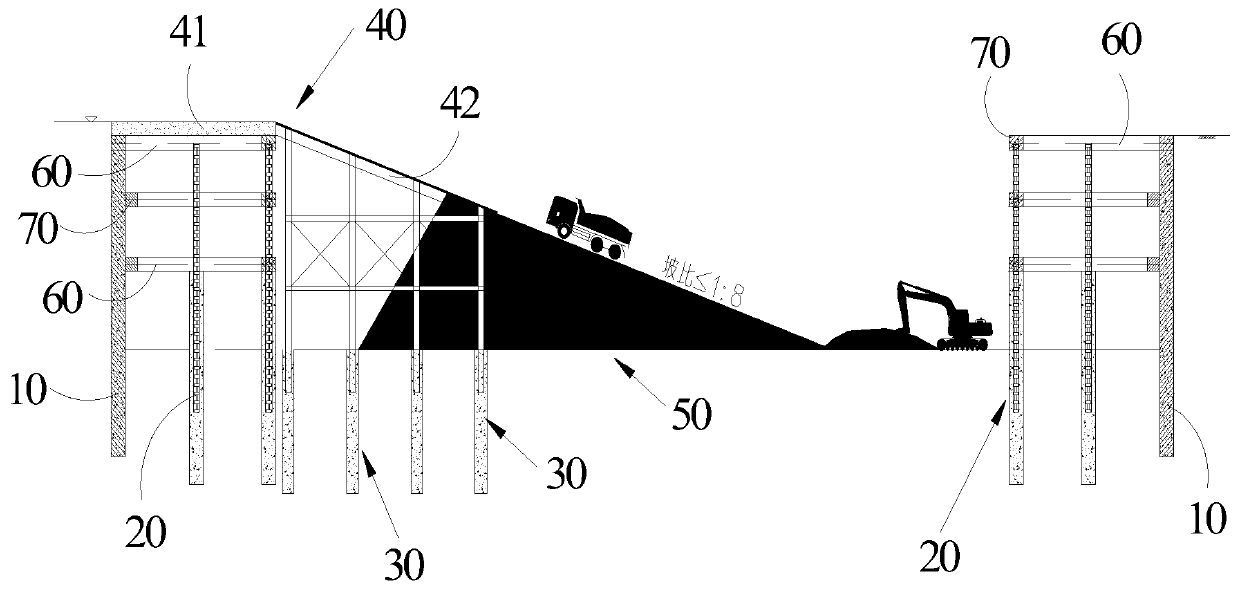

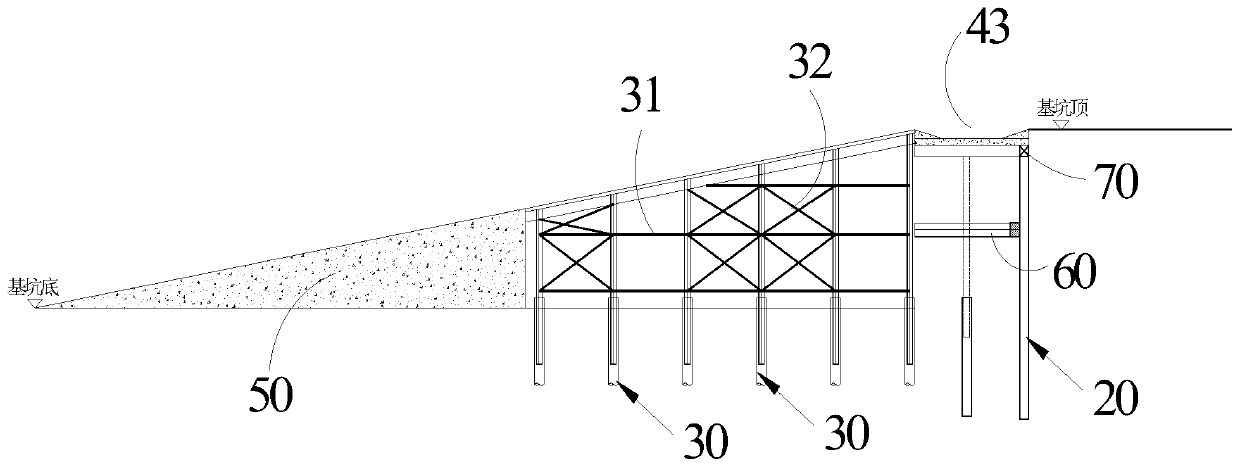

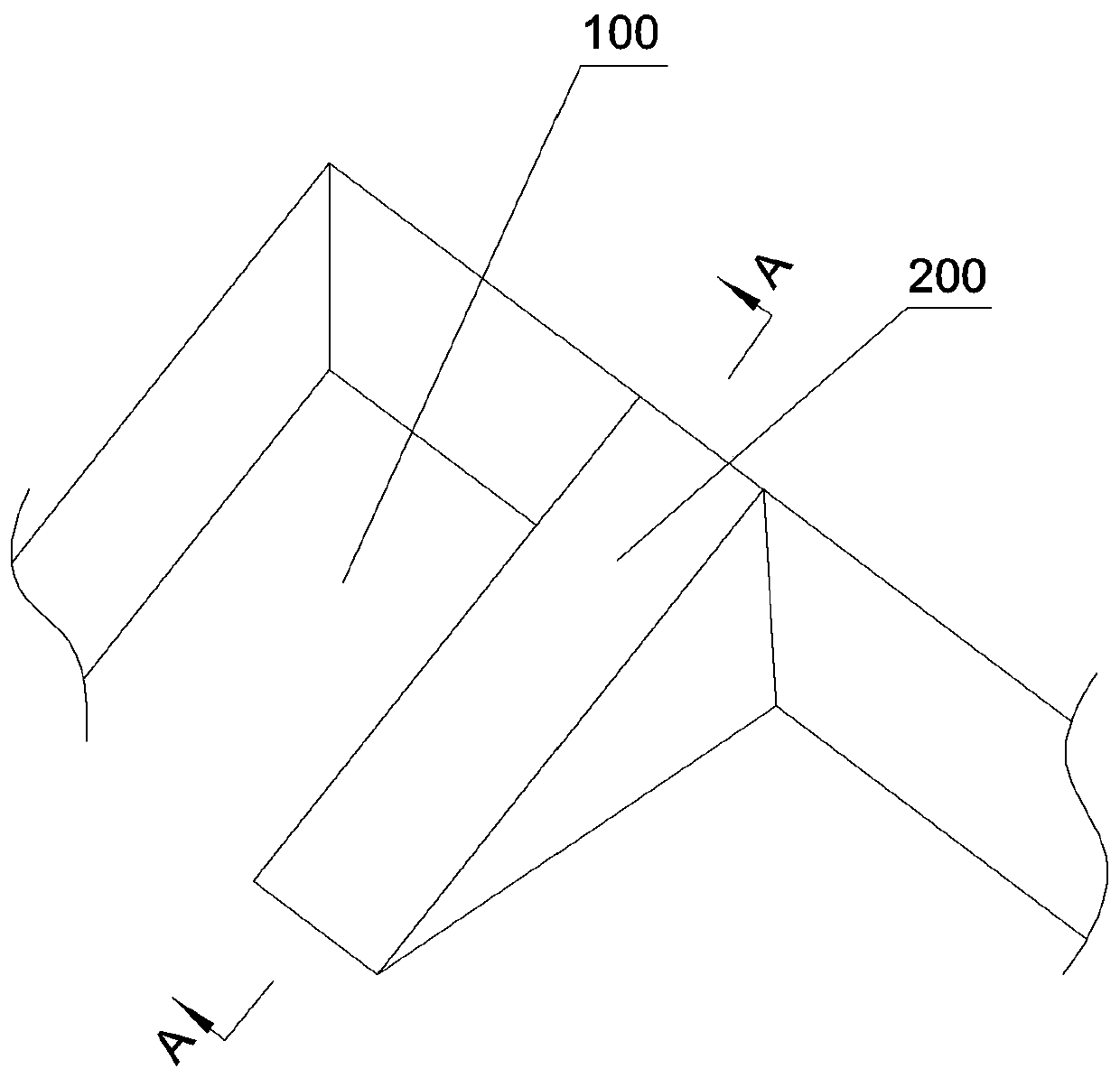

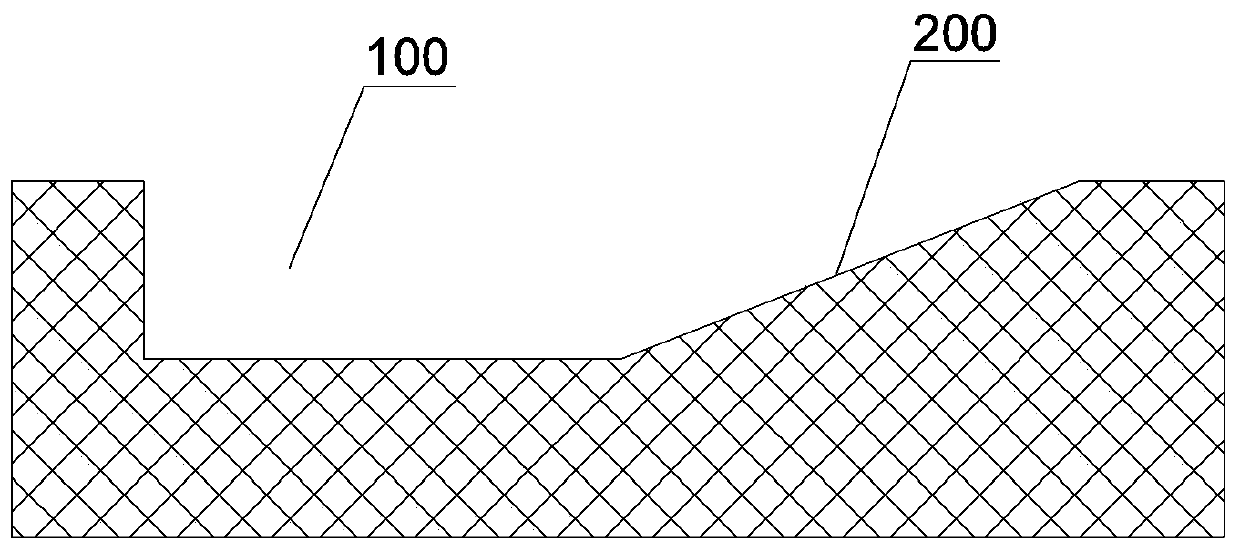

The invention relates to the technical field of deep foundation pit excavation construction, and discloses an annular deep foundation pit excavation construction method.The annular deep foundation pitexcavation construction method comprises the following steps that (1) a support pile,a plurality ofcolumn piles, and a plurality of trestle piles are separately constructed; (2) connecting beams areconstructed, and crown beams are constructed; (3), a trestle is constructed,a trestle deck is formed through pouring, the support pile, each of the trestle piles, and each of the column piles supportthe trestle deck respectively; (4), a reserved soil slope is excavated on a lower layer, the soil slope forms a slope surface, and the slope surface and the trestle deck are connected to form a jointramp; (5) the soil slope extends downward until earthwork is excavated to the bottom of a foundation pit; (6) the earthwork in the foundation pit is excavated and transported outward, the soil slope is gradually collected from bottom to top; and (7) the trestle is demolished. The soil slope earthwork can be formed by slope finishing,the soil slope is part of the excavation of the foundation pit, and the project cost is greatly saved; the earthwork excavation of the foundation pit is avoided, the excavation ramp is repeatedly built for multiple times, the unearthing efficiency is greatly improved, and the construction period is shortened.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

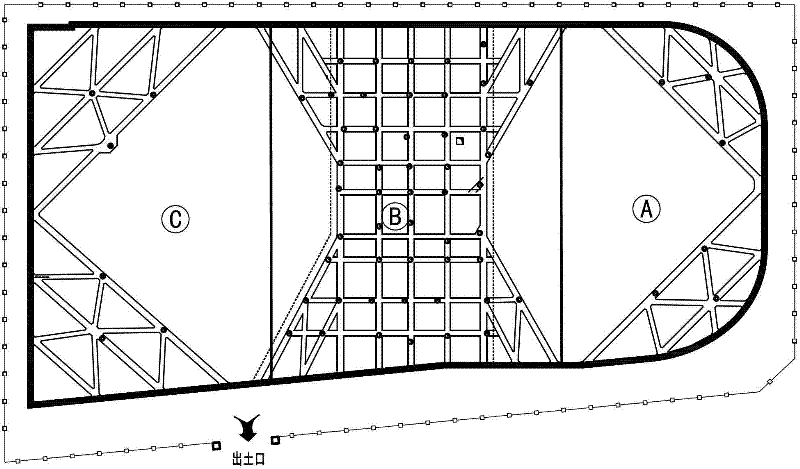

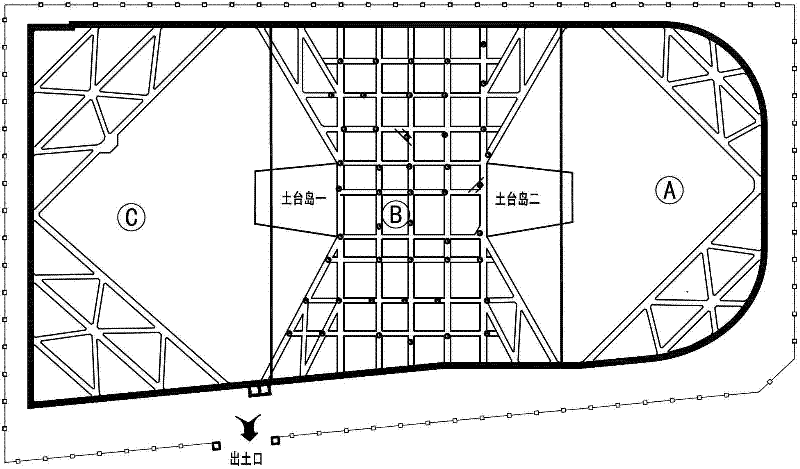

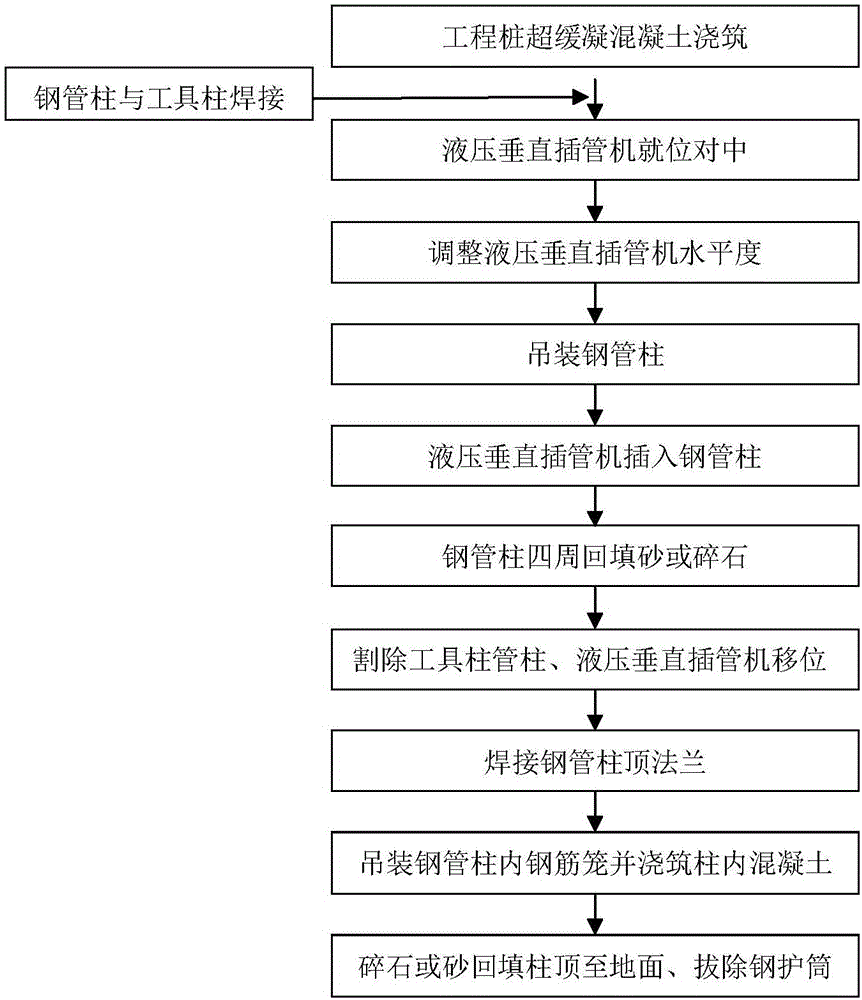

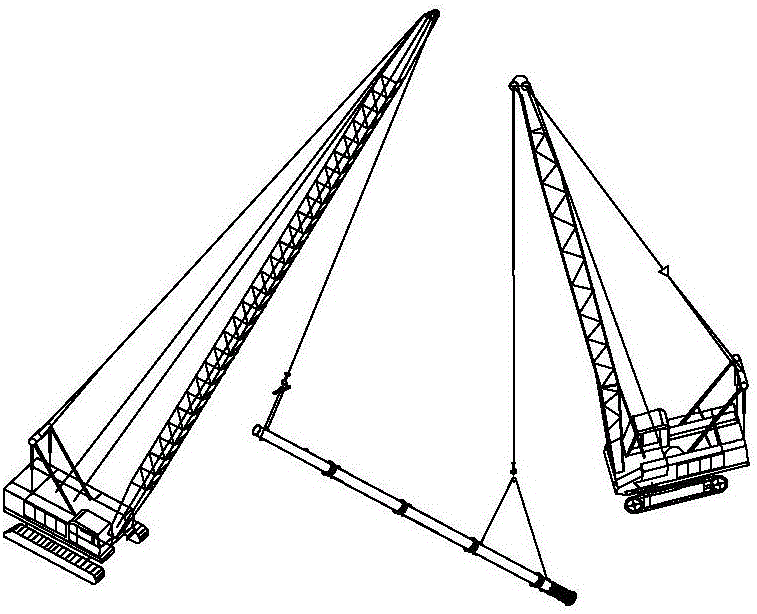

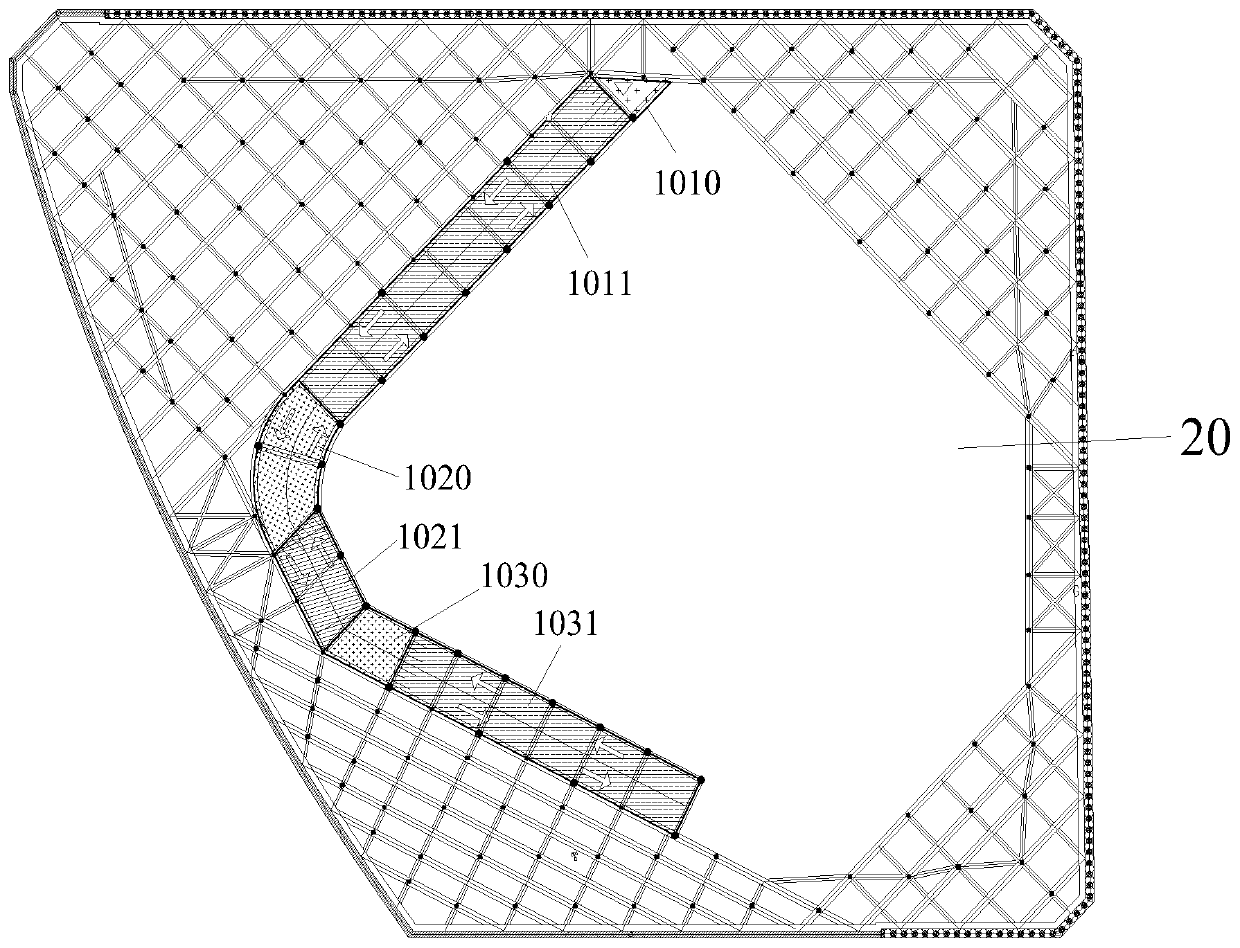

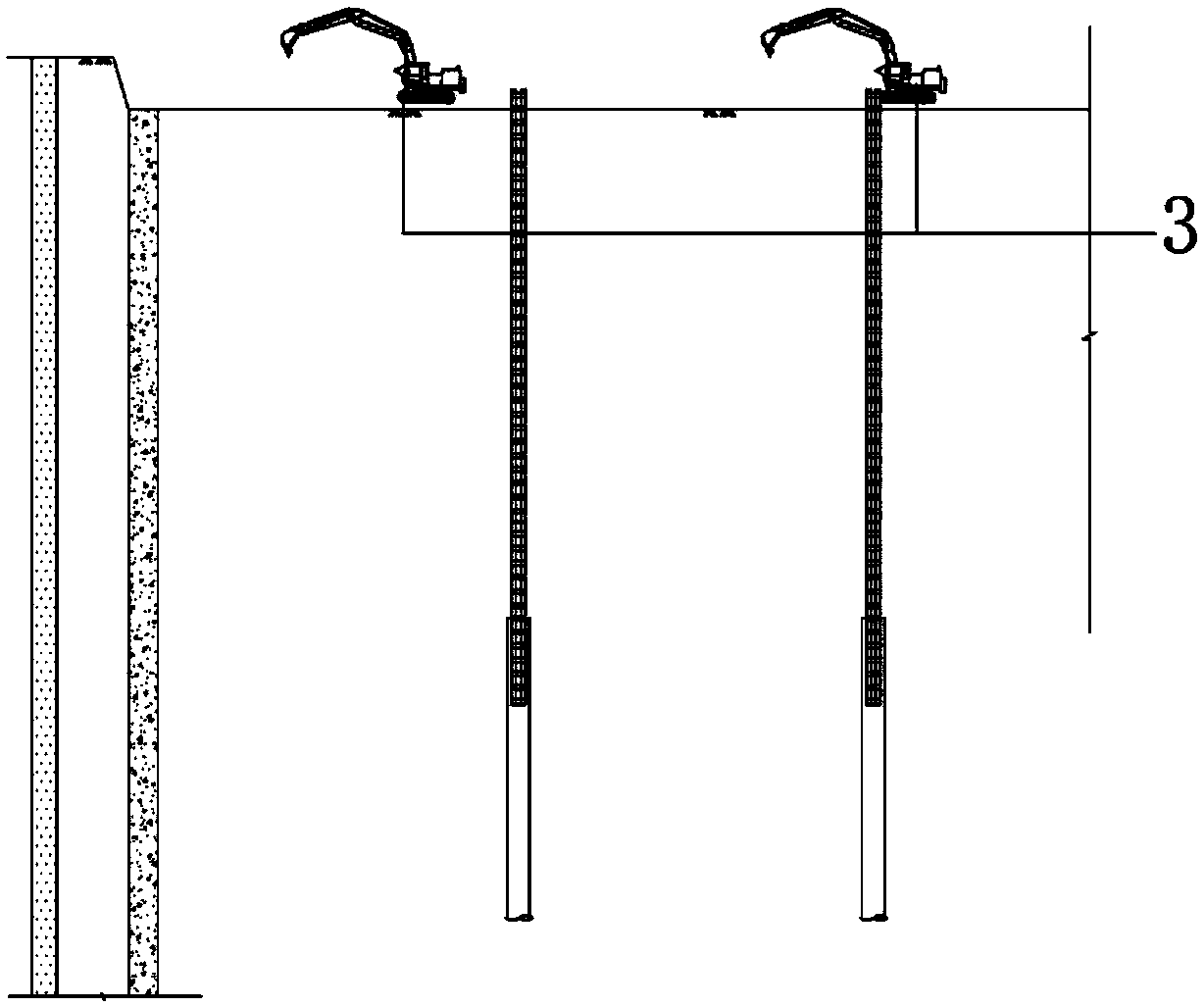

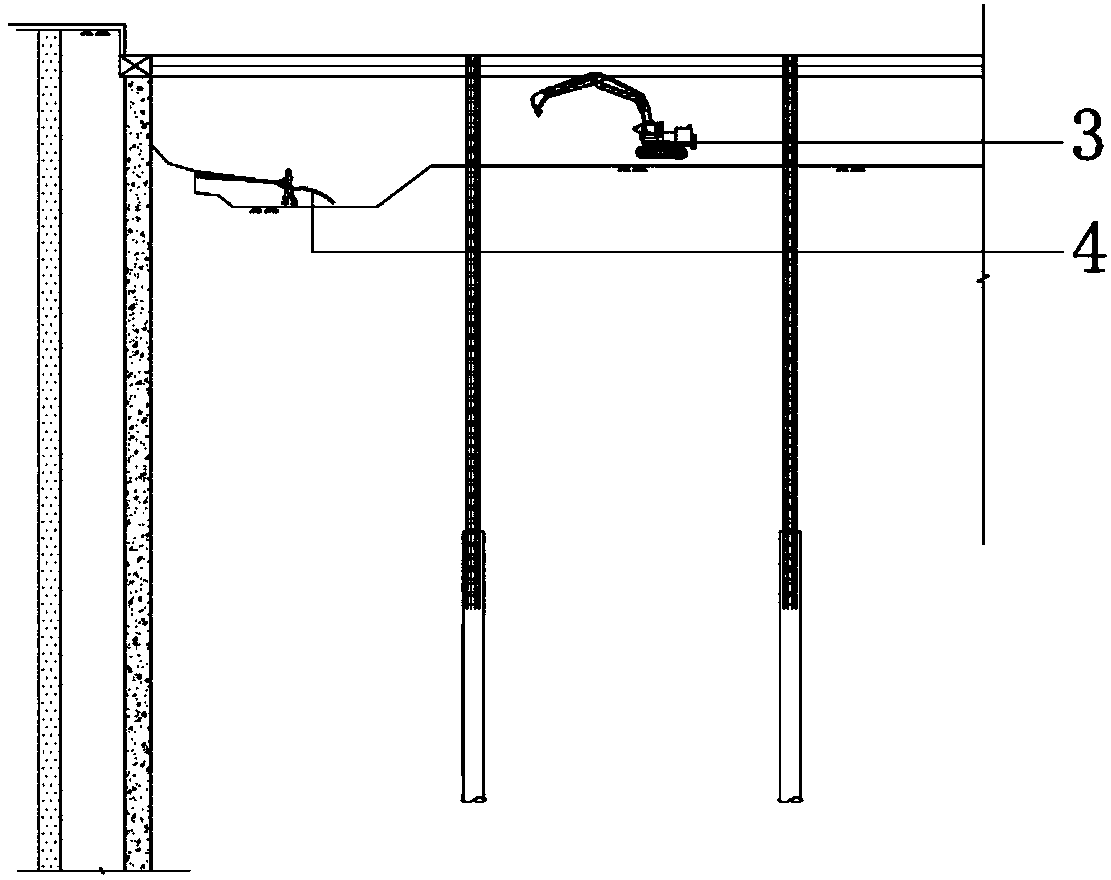

Unitized rapid construction method of cover and excavation top-down metro transfer station

ActiveCN106284410AImprove unearthed efficiencySimplify the construction processArtificial islandsUnderwater structuresEngineeringRapid construction

The invention discloses a unitized rapid construction method of a cover and excavation top-down metro transfer station. The method comprises the steps that the characteristics of a transfer station cross route construction field are utilized, and a slope ramp and vertical shaft combined excavating method is adopted; according to the characteristics of permanent steel pipe columns, a construction method of inserting vertical hydraulic insert pipes into steel pipe columns is adopted to install the permanent steel pipe columns, and a unitized rapid construction technology of the cover and excavation top-down metro transfer station is formed. The unitized technology remarkably improves the excavation efficiency of the cover and excavation top-down station, also greatly simplified a middle pile column constriction process, achieves accurate positioning and rapid construction (the average time for completing installation of each steel pipe column is 10-20 hours), and the safety risks and construction costs are reduced.

Owner:LANGFANG NORMAL UNIV

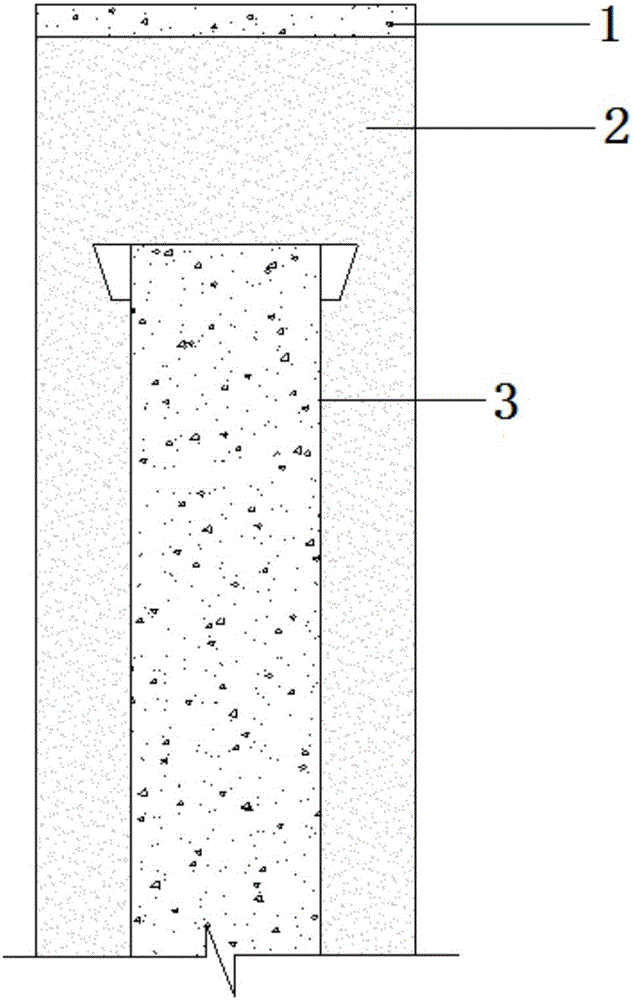

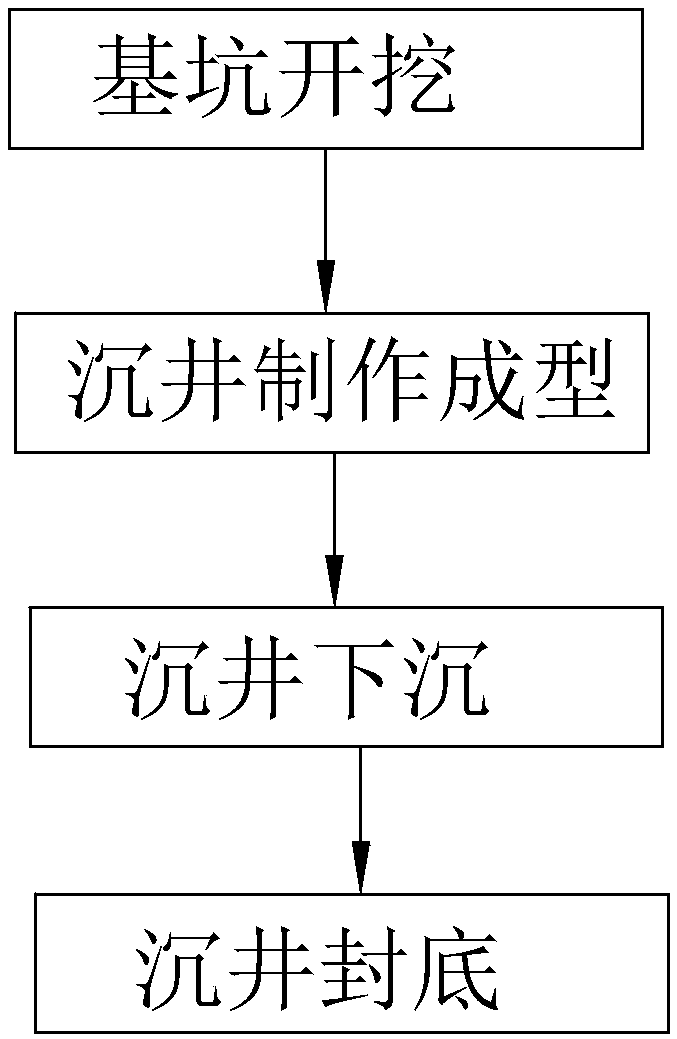

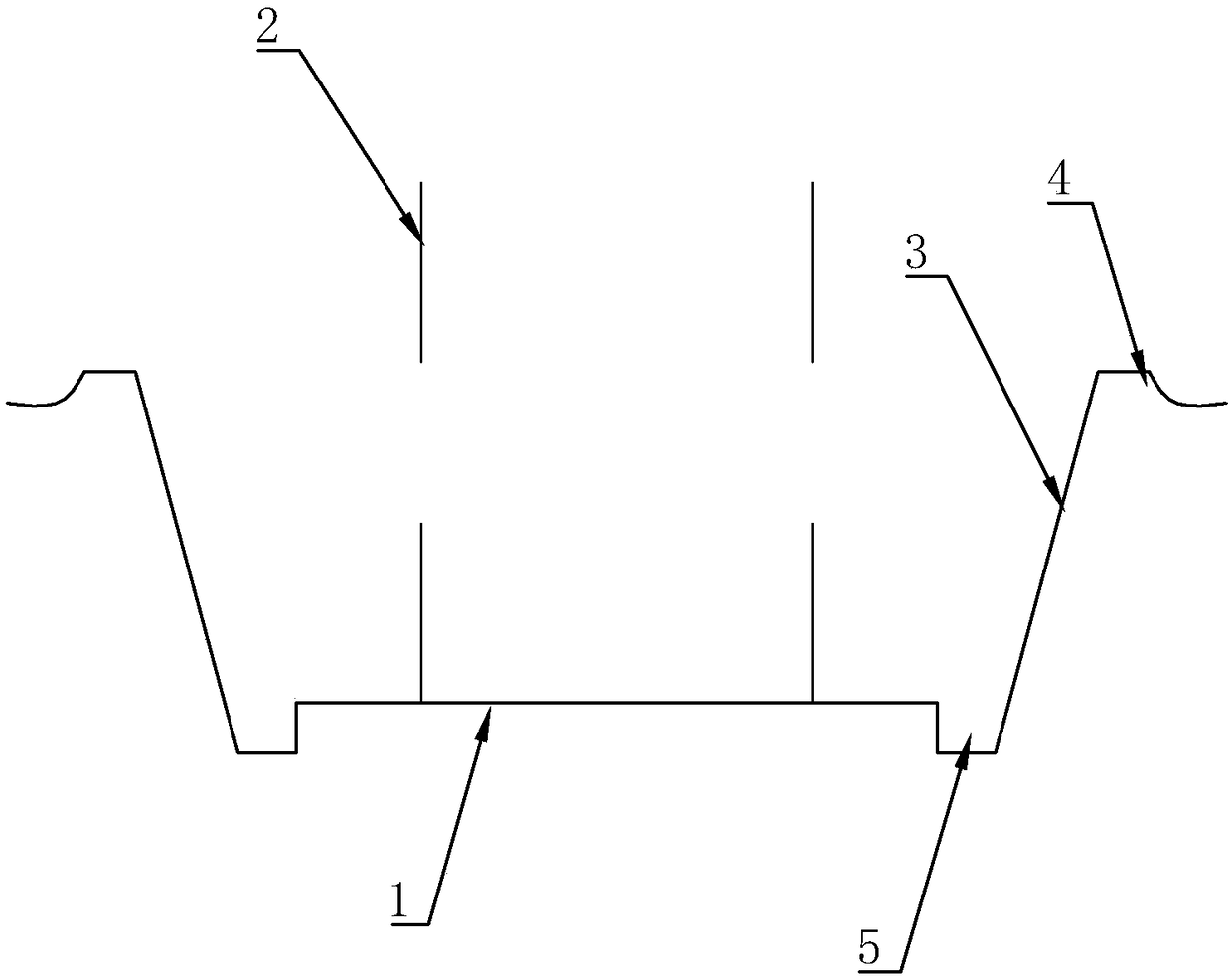

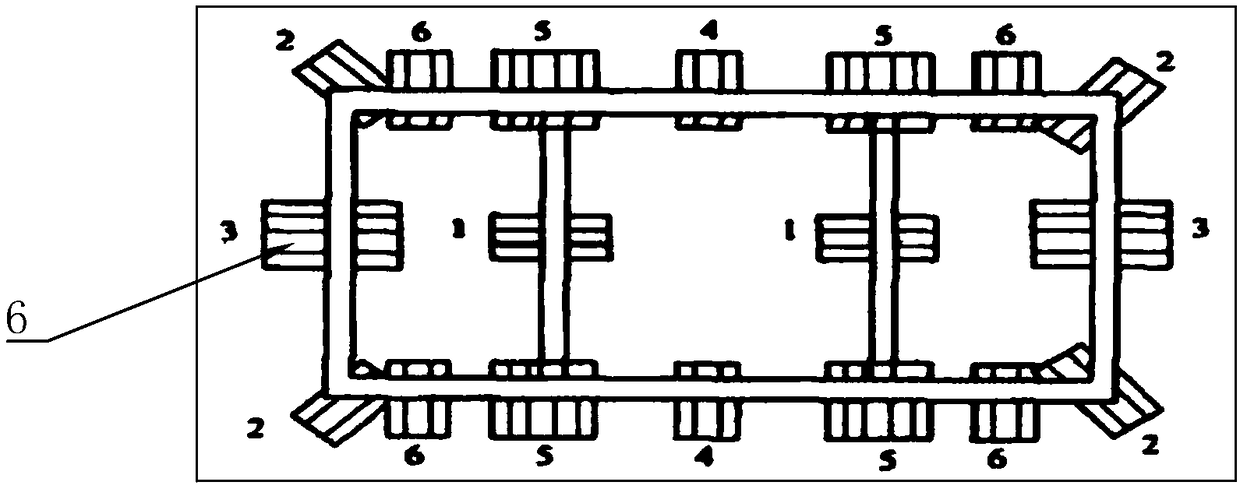

Caisson sinking construction method

InactiveCN108331000AImprove construction efficiencyImprove unearthed efficiencyCaissonsStructural engineeringDrainage ditch

The invention provides a caisson sinking construction method comprising the step (I) of excavation of a foundation pit: excavating the foundation pit at the manufacturing site of a caisson, digging drainage ditches at the edges of the foundation pit for collecting rainwater left in the foundation pit, and laying earth dams at the top edges of the slopes of the foundation pit for preventing rainwater on ground from flowing into the foundation pit; the step (II) of manufacturing and forming of the caisson; the step (III) of sinking of the caisson: a. primary sinking, b. normal sinking and c. final sinking; and the step (IV) of bottom sealing of the caisson. When the caisson sinking construction method is applied to caisson sinking near river or sea fields, sinking is steady and constructionis safe.

Owner:CCCC TDC ENVIRONMENTAL PROTECTION DREDGING

Construction method for earth excavation of deep foundation pit near river

ActiveCN106245652AImprove unearthed efficiencyReduce dust pollutionExcavationsEngineeringRoad traffic

The invention discloses a construction method for earth excavation of a deep foundation pit near a river. The construction method is characterized by comprising the following steps that in the construction process for earth excavation of a deep foundation pit project near the river, mechanical excavation for foundation pit construction and hydraulicking for foundation pit construction are combined according to the actual condition of a foundation pit construction site; hydraulicking is adopted for foundation pit construction when the operating space of a traditional mechanical excavation construction machine is limited or the passing time of an earthwork transport vehicle is limited; and meanwhile, earth is converted into mud during hydraulicking for foundation pit construction, and the mud is directly transported away in a waterway transportation way through a mud ship in the river. Influences on the road traffic around the project are avoided, and the transportation time is not limited. By applying the construction method to construction of a construction project, the earth excavation construction efficiency for the deep foundation pit project can be effectively improved, environmental friendliness is achieved, earth excavation noise is lowered, raising dust pollution is reduced, and time and labor are saved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

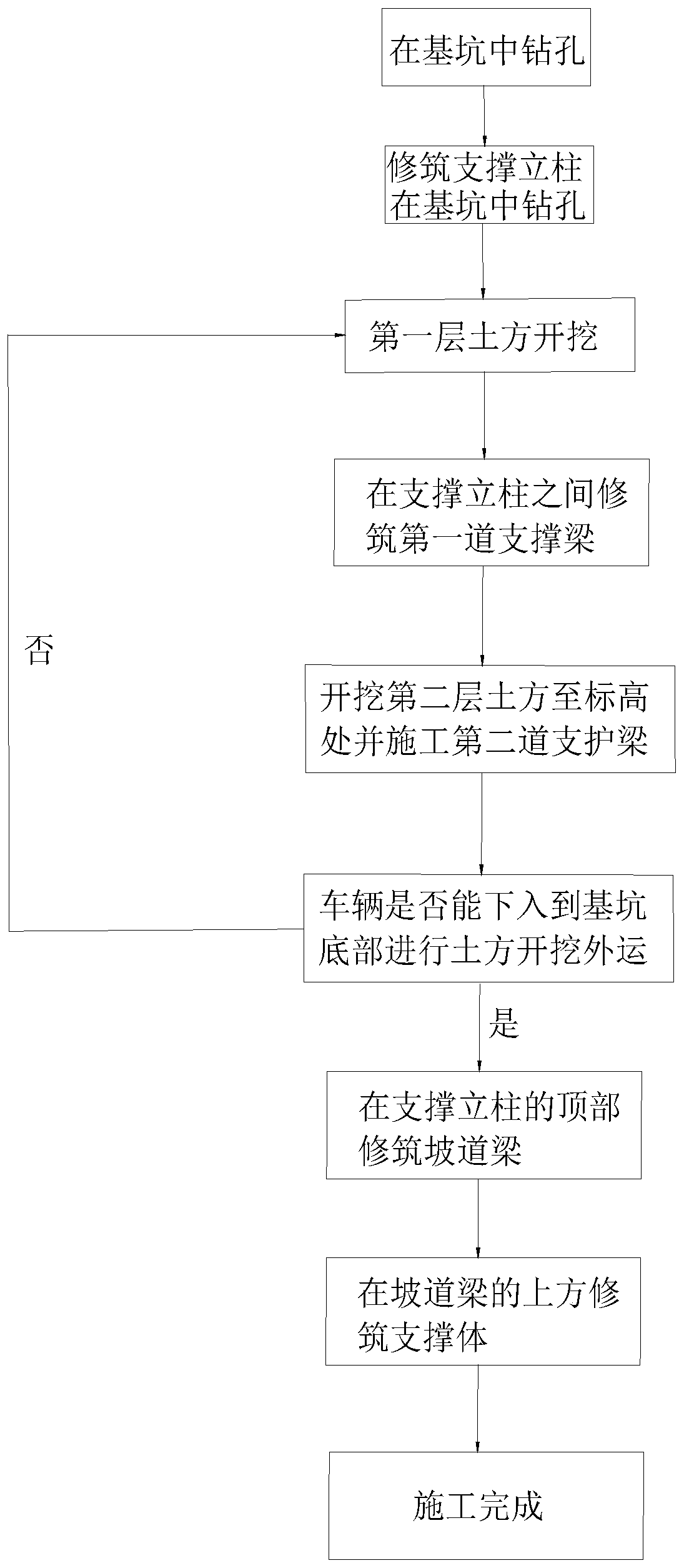

Construction method for internal support foundation pit earthwork transportation ramp

PendingCN110872841AImprove unearthed efficiencyEasy accessExcavationsShaping building partsStructure supportGeotechnical engineering

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD

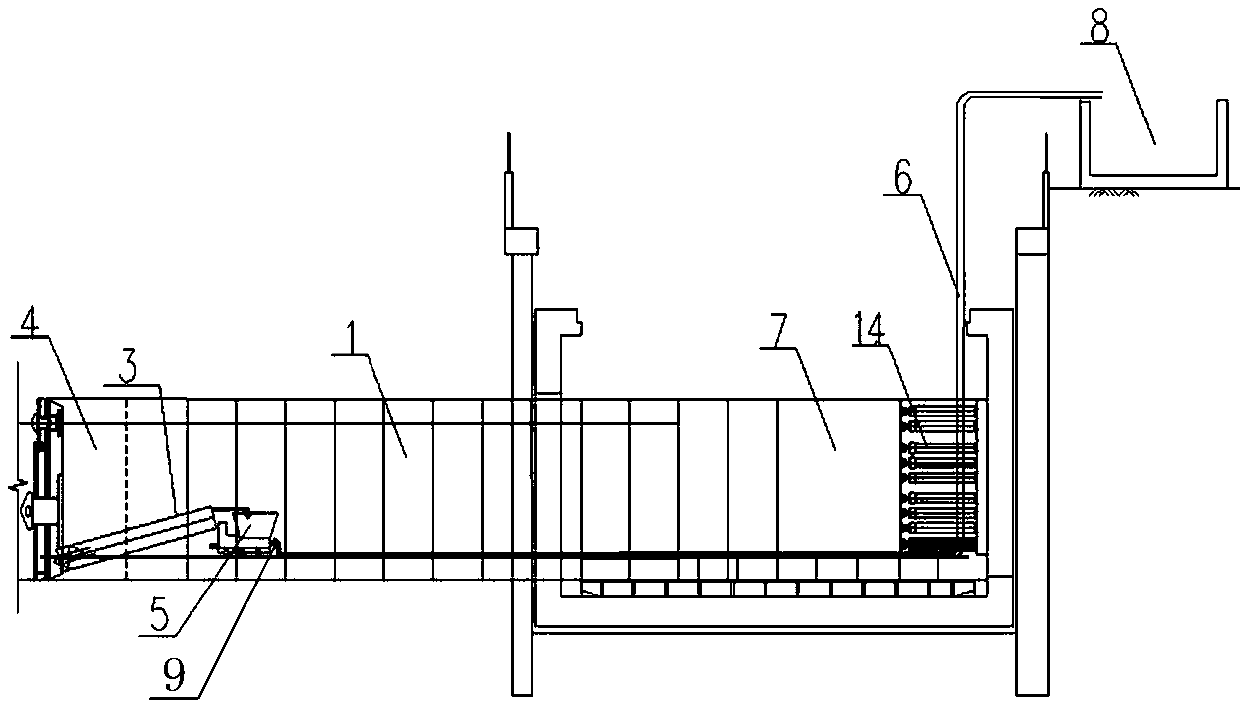

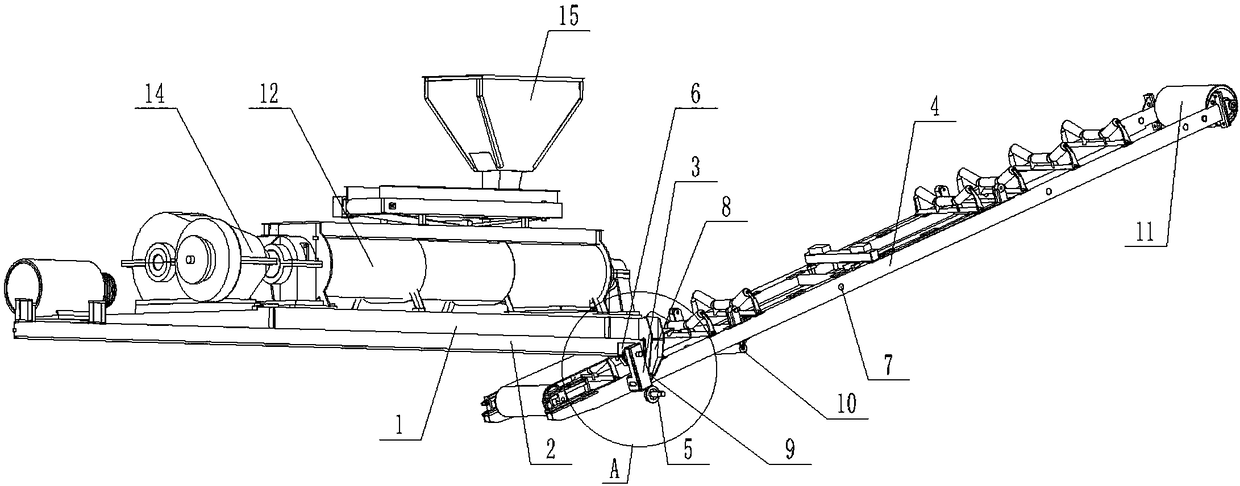

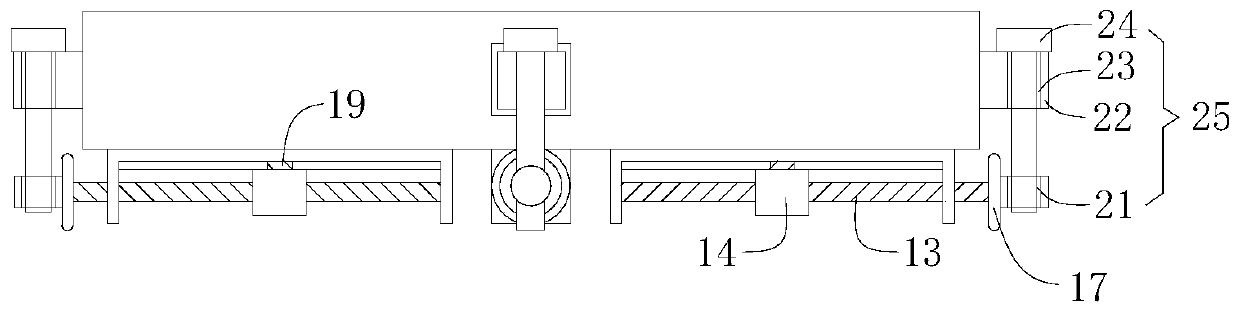

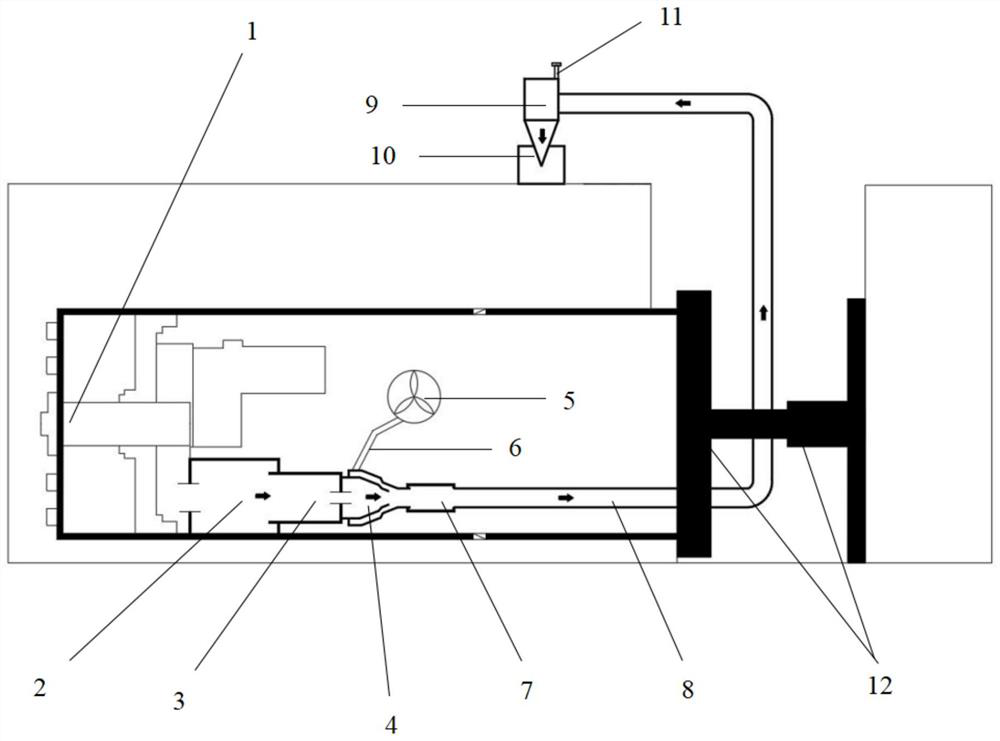

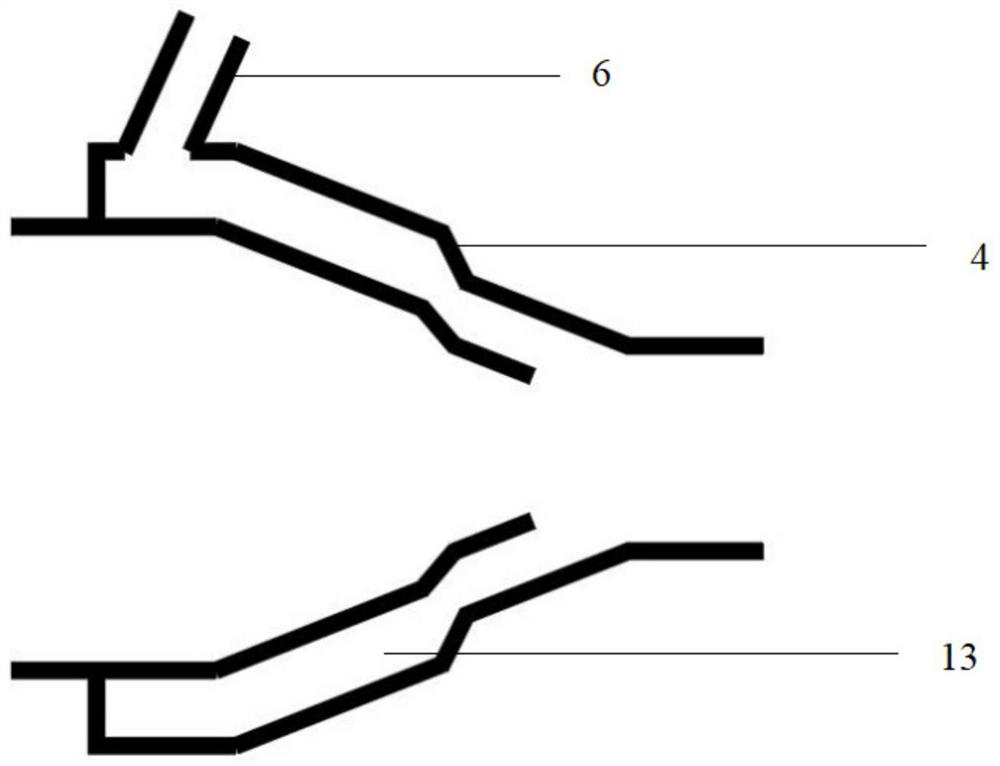

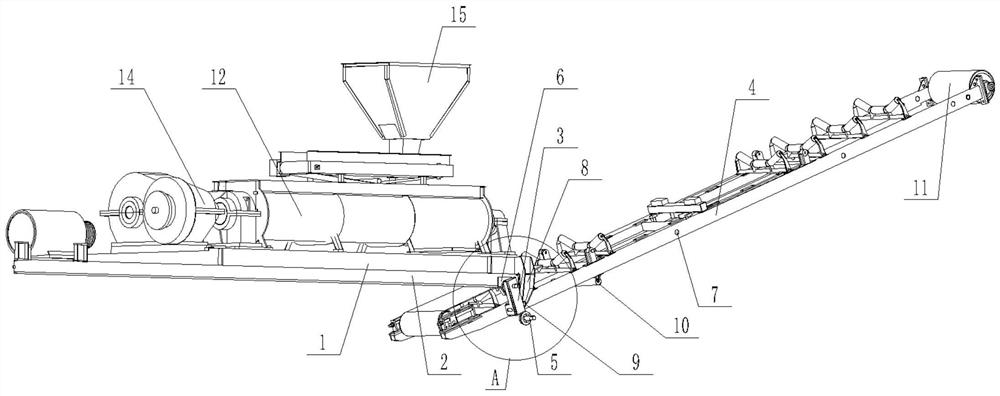

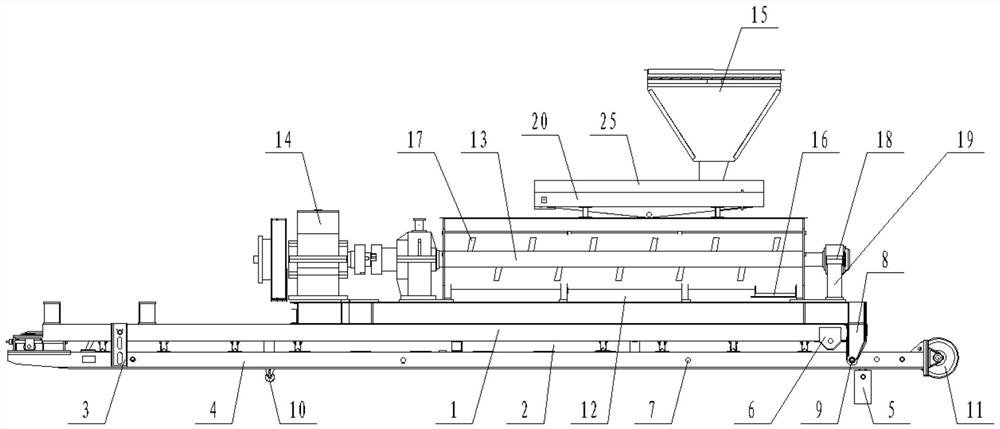

Construction system and method of pipe gallery with integral prefabricated pipe joint and internal partition

PendingCN111287217ASolve the slagSolve the problems that will occur in key links such as groutingArtificial islandsUnderwater structuresInjection portHigh pressure water

The invention relates to a construction system and method of a pipe gallery with an integral prefabricated pipe joint and internal partition. The pipe gallery includes the integral prefabricated pipejoint and internal partition; grouting holes are formed in the side wall of the pipe joint; the construction system includes an unearthed system, an antifriction grouting pipe system and a jacking system; the unearthed system includes a spiral unearthing machine, a supporting pump and a pump pipe; the supporting pump pipe is connected with the spiral unearthing machine; one end of the pump pipe isconnected with the supporting pump, and the other end of the pump pipe is extended into a residue pool; a high pressure water injecting ring is arranged between the pump pipe and the supporting pump;the antifriction grouting pipe system includes grouting pipes and grouting valves; the grouting valves and the grouting holes are arranged correspondingly; the grouting valves comprise transverse pipe sections and longitudinal pipe sections; ports of the longitudinal pipe sections are connected with the grouting holes; the number of the grouting pipes is two less than the number of the grouting valves, and the grouting pipes are correspondingly connected among the adjacent grouting valves; ports of one ends of the two grouting valves at the very bottom are left as slurry injection ports; andembedded steel pipes are arranged on the internal partition. The construction system and method of the pipe gallery with the integral prefabricated pipe joint and internal partition solve the technical problem that the integrity of the pipe joint and the internal partition is poor in the construction of a traditional pipe-jacking pipe gallery, and the field assembly or the cast-in-place construction is not easy.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Method for setting double-triple soil taking openings by reverse construction method

InactiveCN102733394AImprove unearthed efficiencyUnearthed efficiency shortenedExcavationsWork periodFloor slab

The invention discloses a method for setting double-triple soil taking openings by a reverse construction method. Under the condition without influencing the first-layer vehicle running and the stability of a structure support system in the construction stage of the reverse construction method, the support and force transfer requirements of the reverse construction stage can be met by adopting a framework beam or the combination of the framework beam and a local triangular plate support form bottom to top in the region through the structure checking, on the premise, structures such as secondary beams, floor slabs and the like between two adjacent strides or three adjacent strides adopt post construction, and vacant regions of adjacent two-cabin or three-cabin floor slabs are set as soil taking openings. Through the arrangement of the double-triple soil taking openings, the contradiction between soil taking opening soil accumulation and the soil taking and the problem of vertical earthwork transporting passage are solved, the soil taking and the soil accumulation can be carried out in different hole positions, then, the position exchange regulation is carried out, the three-dimensional crossed construction is avoided, the soil outlet efficiency is improved, the soil digging time is shortened, the work period is saved, and the construction progress is ensured.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Integration system and method of body and supporting structure of foundation pit

PendingCN108643195ALow costImprove unearthed efficiencyExcavationsStructure of the EarthStructural engineering

The invention provides an integration system and method of a body and a supporting structure of a foundation pit. According to the integration system and method of the body and the supporting structure of the foundation pit, firstly, a first underground body structure of a certain width is formed around the foundation pit, after the first underground body structure is constructed and maintained todesign strength, the first underground body structure is directly used for being combined with an outside enclosure wall, the integration of the first underground body structure and the outside enclosure wall is used as the enclosure system of a later-period middle foundation pit digging, and after the surrounding integrated enclosure system is constructed, earthwork in the to-be-excavated area in the middle is excavated out in a heavy excavation manner. By the adoption of the integration method of the body and the supporting structure of the foundation pit, it is avoided that a large numberof temporary supports are erected in the foundation pit, so that the construction cost of the project is greatly reduced; and meanwhile, the surrounding first underground body structure and the outside enclosure wall are integrated to be used as the enclosure system of the foundation pit, so that the problem that flowing deformation of remaining soil around the foundation pit causes excessively large deformation of the foundation pit is avoided, and foundation pit surrounding environment protection is facilitated.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

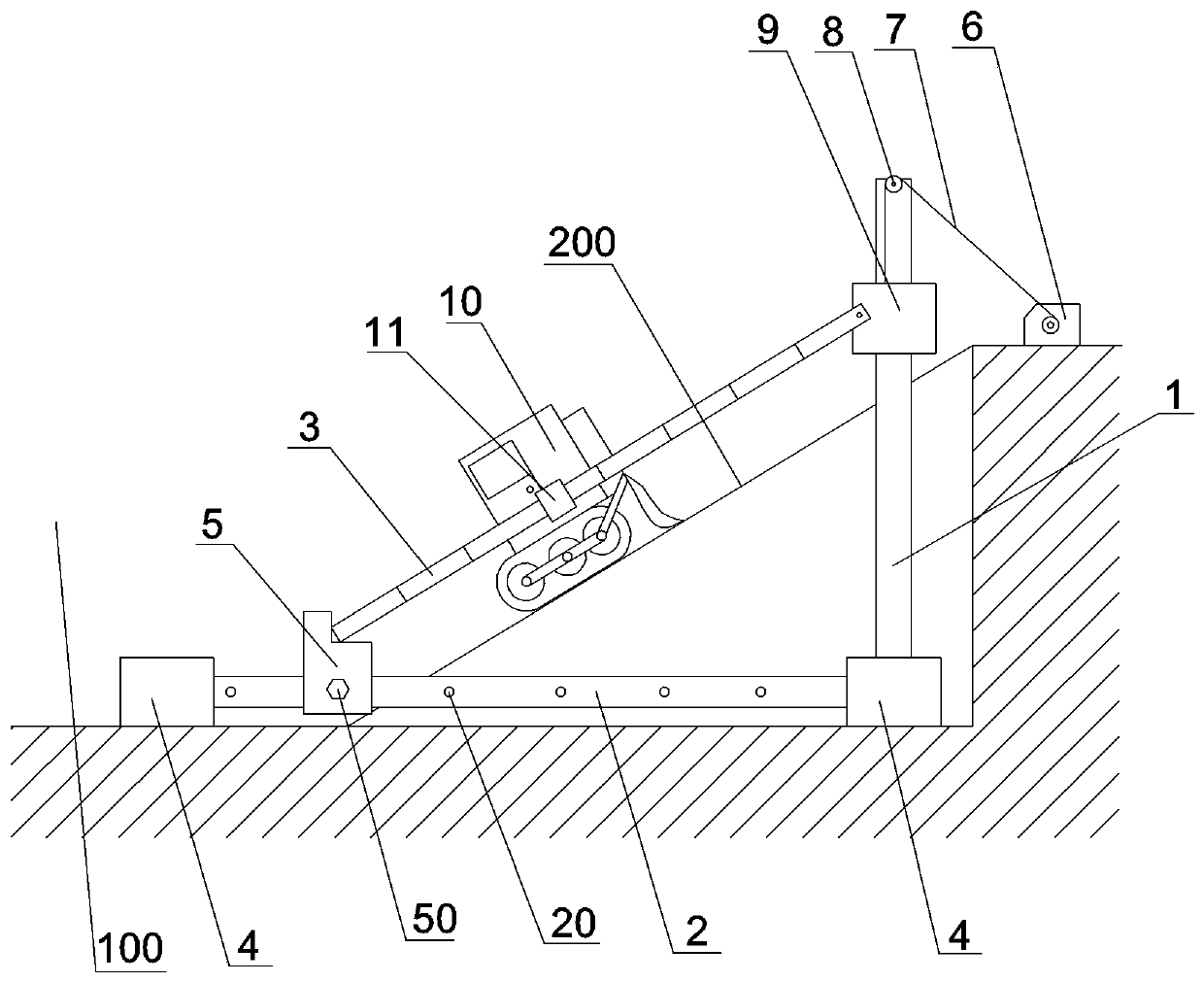

Foundation pit soil moving-out device

InactiveCN110158683ARealize disassemblyAvoid blockingMechanical machines/dredgersExcavationsEngineeringTower crane

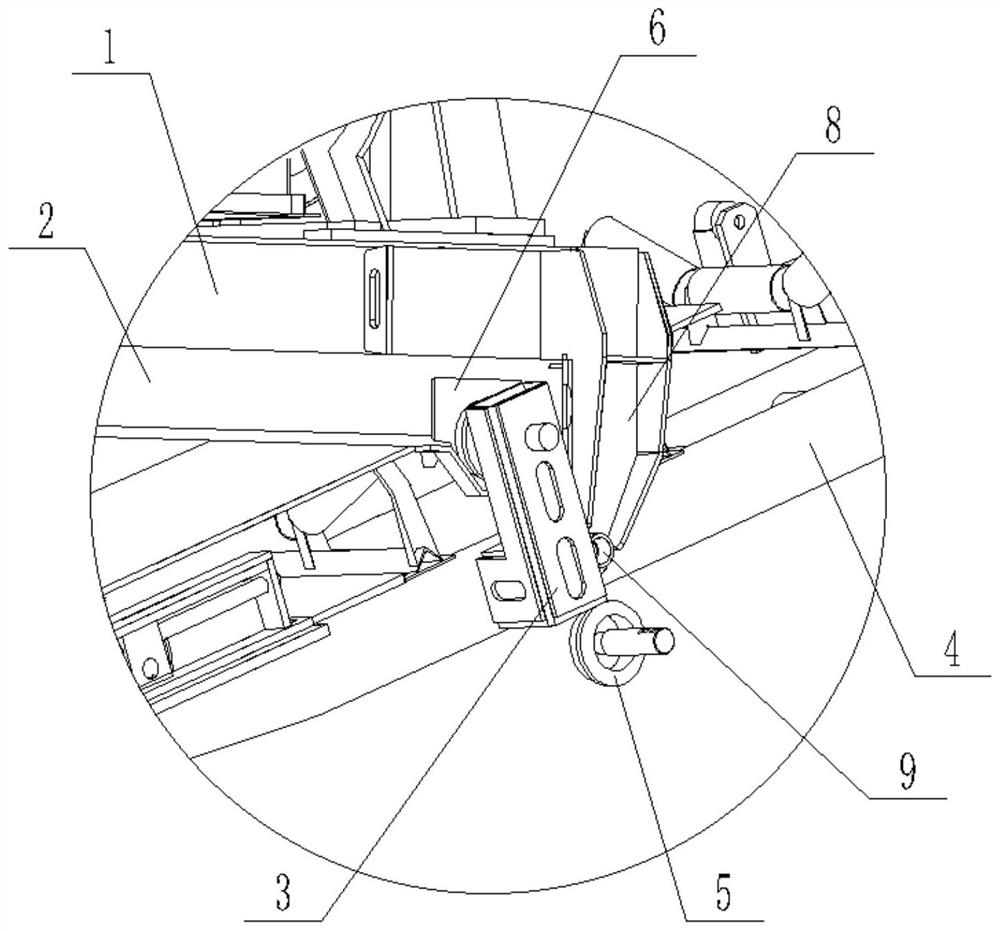

The invention belongs to the field of building construction, and particularly discloses a foundation pit soil moving-out device. The foundation pit soil moving-out device comprises supporting and guiding mechanisms arranged on the side edges of a foundation pit ramp and a soil moving-out mechanism arranged on the foundation pit ramp; each supporting and guiding mechanism comprises a vertical supporting rod, a horizontal supporting rod and an inclined guide rod; each vertical supporting rod is fixed at the side edge of the top end of the foundation pit ramp; each horizontal supporting rod is fixed at the bottom of the side edge of the foundation pit ramp; each inclined guide rod is parallel to the upper surface of the foundation pit ramp; the top end of each inclined guiding rod is slidingly connected to the corresponding vertical supporting rod; each inclined guide rod is formed by splicing a plurality of segments; a segment installation gap is formed between the bottom end of each inclined guide rod and the corresponding horizontal supporting rod; and each horizontal supporting rod is slidingly connected with a segment supporting part capable of filling the corresponding segment installation gap. The soil moving-out mechanism comprises a trolley which is slidingly connected to the inclined guide rods; and a soil bulldozing part is arranged on the trolley. The special soil moving-out device is designed for ramp soil of a foundation pit, and a tower crane is not occupied when the ramp soil of the foundation pit is moved out.

Owner:CHONGQING CONSTR ENG SECOND CONSTR CO LTD

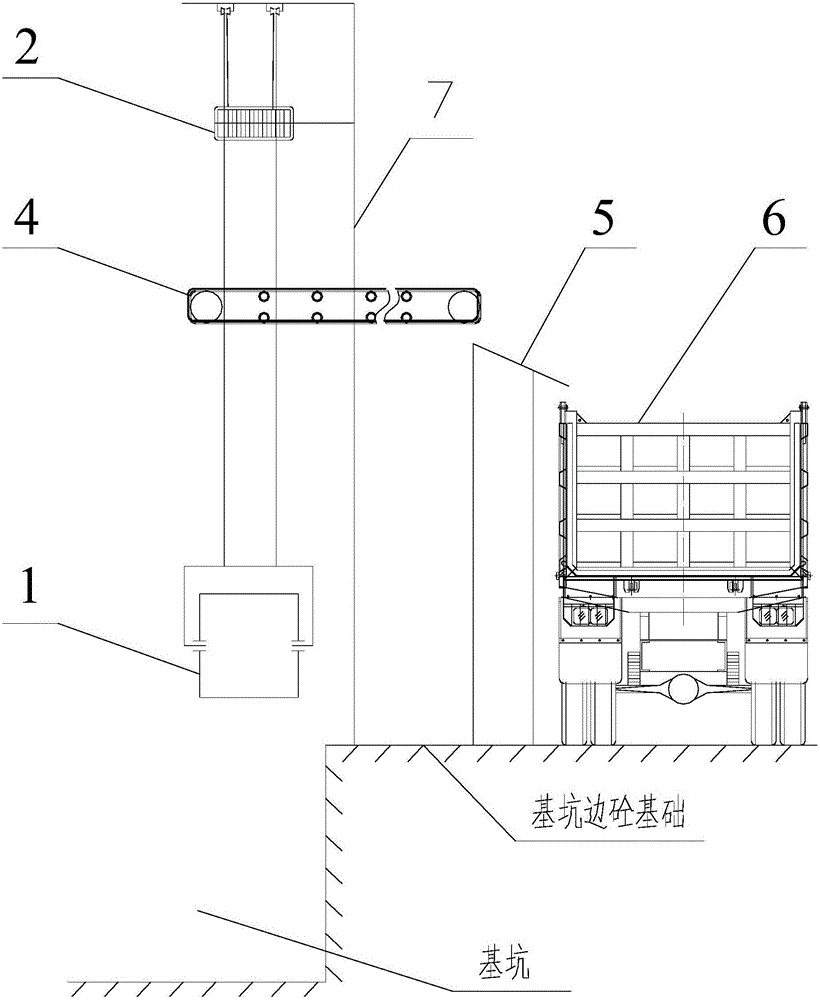

Rapid soil sampling system and method for constructing ultra-deep shaft foundation pit

The present invention relates to a rapid soil sampling system and method for constructing an ultra-deep shaft foundation pit; the system includes vertical soil sampling equipment, a soil piling platform, a soil collection pit, a temporary protection frame and a soil collection box, wherein the vertical soil sampling equipment adopts a slide rail gantry crane; the temporary protection frame is connected with the ground wall of the ultra-deep shaft foundation pit through embedded anchor plates; the soil piling platform is arranged in an area that is located at the edge of the opening of the ultra-deep shaft foundation pit and formed by pouring reinforced concrete; the soil collection pit is arranged on the soil piling platform and positioned on the track path of the slide rail gantry crane,and the slide rail gantry crane is connected with the soil collection box through a sling. In order to prevent the soil collection box from collision during vertical soil sampling, the temporary protection frame is arranged around the soil collection box; the soil collection pit can temporarily store earthwork that cannot be transported out in time; in use, the gantry crane soil sampling equipmentis not limited by the depth of the on-site foundation pit, so that the soil sampling efficiency is improved, and thus the gantry crane soil sampling equipment is particularly suitable for soil sampling of the ultra-deep foundation pit with narrow sites.

Owner:SHANGHAI FOUND ENG GRP

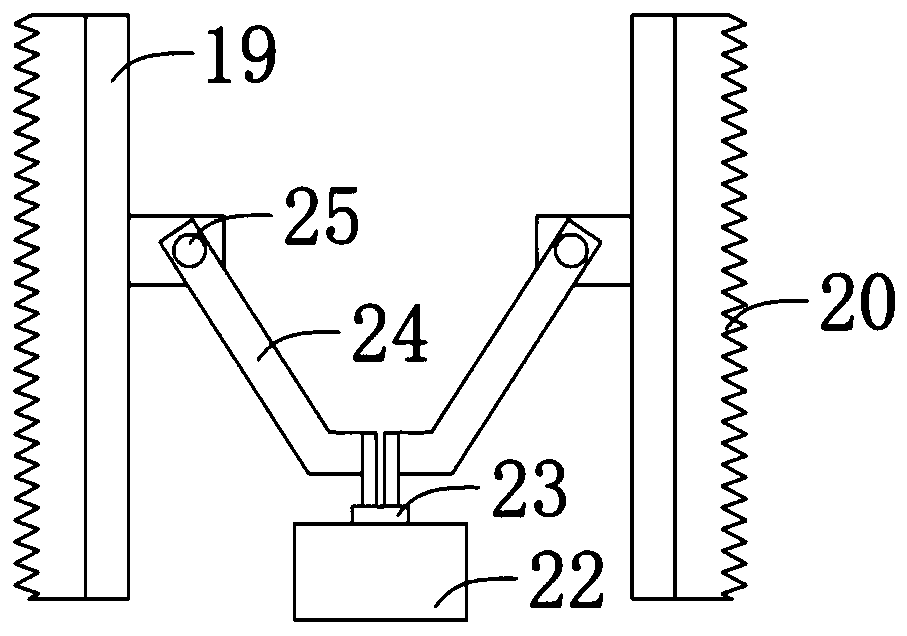

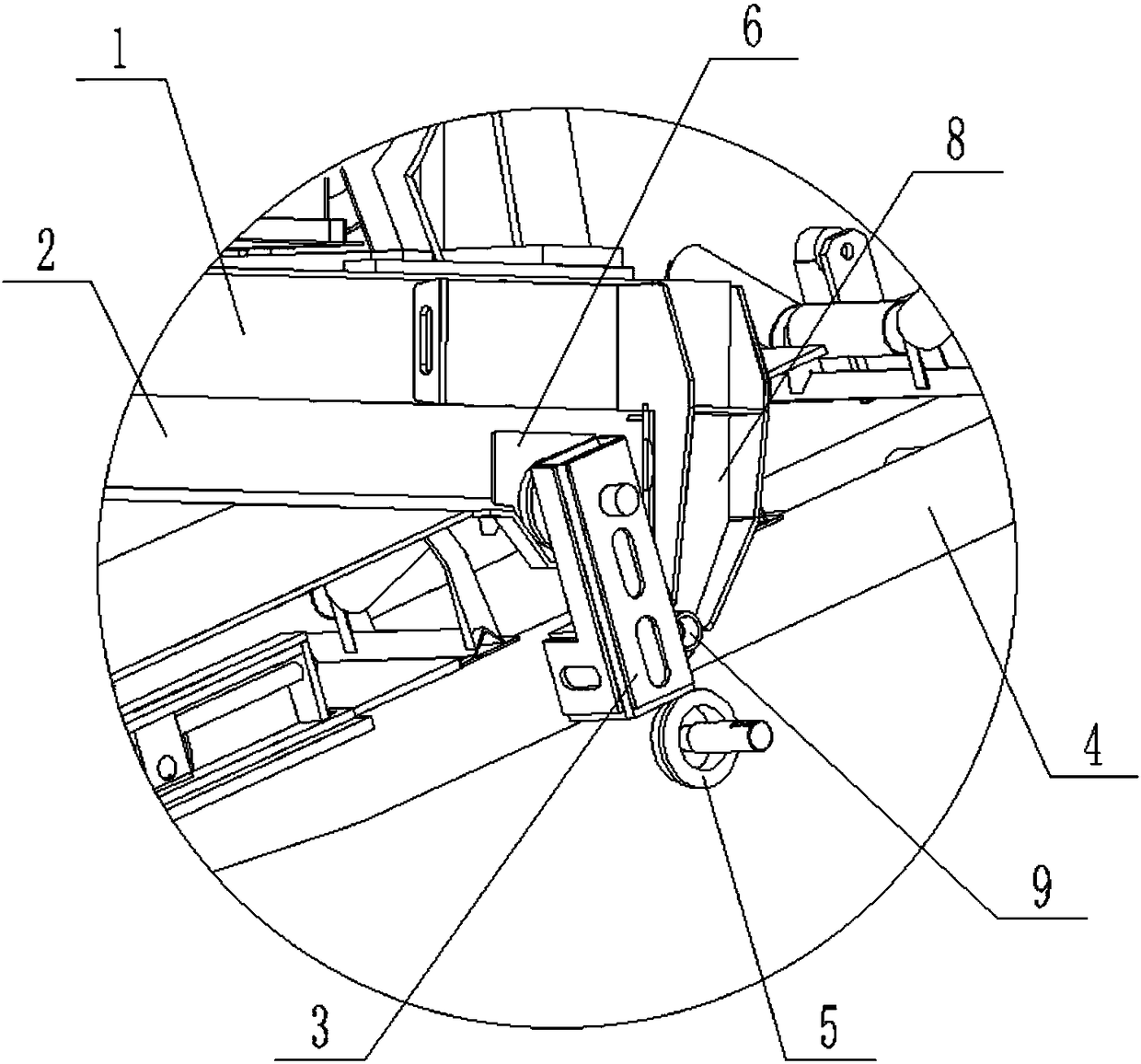

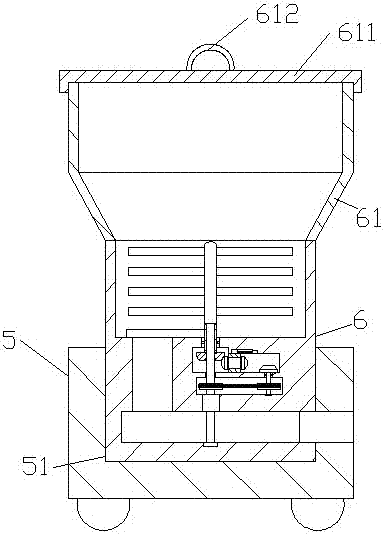

Material lifting and transferring device and method for foundation pit excavation residue soil

InactiveCN105951845AImprove unearthed efficiencySimple structureExcavationsPower componentHinge angle

The invention discloses a material lifting and transferring device and method for foundation pit excavation residue soil. The device comprises a material hopper, a rack, a lifting mechanism and an unloading mechanism, wherein a movable lifting handle is rotatably arranged on the material hopper; the outer side surface of the material hopper is horizontally provided with a cross rod; the upper end of the lifting mechanism is fixedly arranged on the rack, and the lower end of the lifting mechanism is connected with the movable lifting handle; the unloading mechanism comprises a swinging hook and a power component; the hinge axis of the swinging hook is parallel to the cross rod; and the lower end of the swinging hook is provided with a clamping part. The material lifting and transferring device is simple in structure; and the residue soil can be vertically conveyed to a loading and outward transferring area from a foundation pit.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Soil remediation equipment with efficient mixing system

InactiveCN108160697ASave storage spaceEasy to pullContaminated soil reclamationSoil remediationDevices fixation

The invention discloses soil remediation equipment with an efficient mixing system. A slide way is arranged at the bottom of a table body and provided with a first bearing, and the first bearing is installed on a first bearing pedestal; the first bearing pedestal is fixedly connected with a linear conveying device; the soil remediation equipment further comprises a supporting piece connected to the lower end of the linear conveying device; the table body is provided with a storage bin, a stirring shaft is arranged in the storage bin, and a drive device is arranged outside the storage bin and used for driving the stirring shaft to rotate a plurality of blades are evenly distributed on the stirring shaft, and the included angle between the blades and the axis of the stirring shaft is 30-40 degrees; and the storage bin is connected with a chemical adding hopper, a discharge outlet is formed in the lower portion of the storage bin, a transfer frame is arranged below the chemical adding hopper, the upper portion and the lower portion of the transfer frame are open, an elastic sheet is laid in the transfer frame, one end of the elastic sheet is fixed, the other end of the elastic sheet is connected to a rotary shaft, and the rotary shaft is driven by a variable frequency motor. The soil remediation equipment with the efficient mixing system is used for solving the problems that in the prior art, soil remediation equipment occupies a large space and is difficult to transfer for use, and achieves the purposes that the occupied storage space is reduced and moving is convenient.

Owner:ANHUI HEKUANG MACHINERY

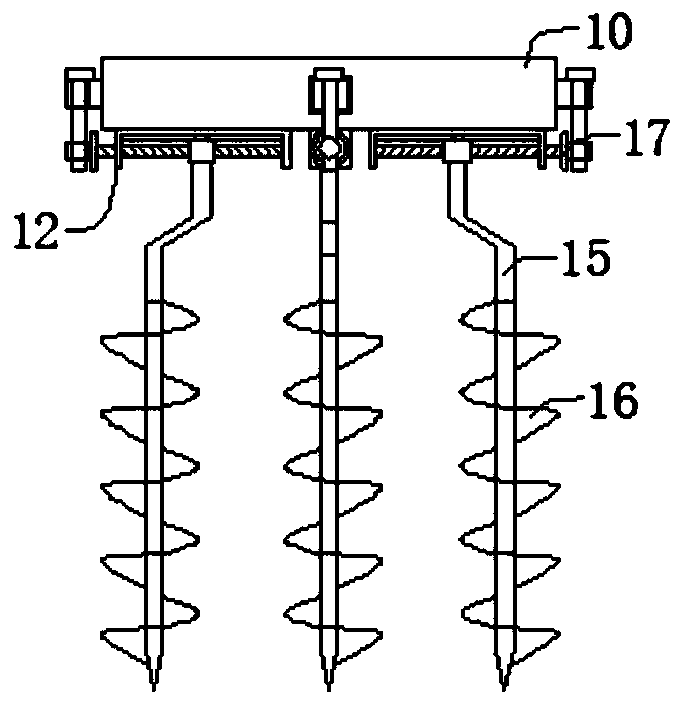

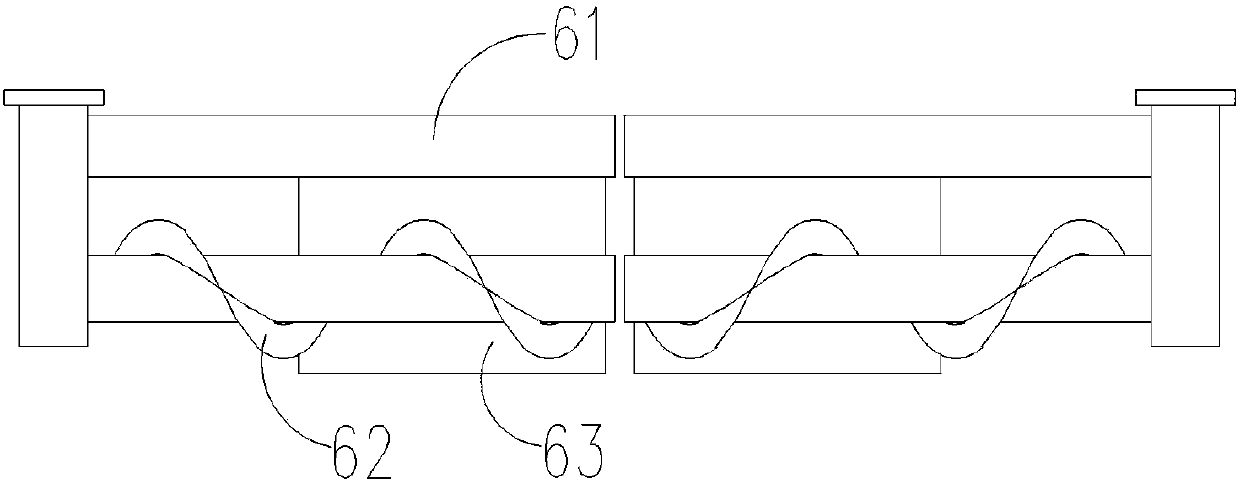

Vineyard unearthing device and vineyard unearthing method

ActiveCN108650899AAvoid damageAvoid the problem of incomplete soil clearingSoil-working equipmentsEngineeringTractor

A vineyard unearthing device and a vineyard unearthing method are provided to solve the problems that an existing vineyard unearthing mode cannot accurately judge an earth scraping depth, the earth scraping is not thorough or branches and tendrils are damaged, the mechanical loss is large and the unearthing efficiency is low. In the unearthing device, the two ends of a vertical rolling shaft are disposed in an upper connecting plate and a lower connecting plate respectively through bearings, two horizontal rolling shafts are symmetrically disposed on the two sides of the vertical rolling shaft, the two horizontal rolling shafts are in obtuse angle or right angle arrangement, a large rope passes across the vertical rolling shaft, one end of the large rope extends out from the upper surfaceof the horizontal rolling shaft on the left side, and the other end of the large rope extends out from the upper surface of the horizontal rolling shaft on the right side. The unearthing method includes the first step of causing the branches and tendrils to fall from a frame before earthing in autumn, covering the grape branches and tendrils with a grass-proof cloth, and covering the grass-proof cloth with a soil layer; the second step of binding the two ends of the large rope to the grass-proof cloth and a column respectively; the third step of connecting the unearthing device with a tractor;and the fourth step of causing the tractor to advance and drive the large rope to drag the grass-proof cloth for unearthing. The vineyard unearthing device and the vineyard unearthing method are usedfor planting grapes.

Owner:HORTICULTURE INST OF XINJIANG ACAD OF AGRI SCI

Mechanical arm of earth auger

PendingCN110607816AImprove digging effectImprove unearthed efficiencySoil-shifting machines/dredgersPower gridDrill bit

The invention aims to provide a mechanical arm of an earth auger. The mechanical arm comprises a lifting device and a variable-diameter drill bit device arranged on the lifting device, and is characterized in that the variable-diameter drill bit device comprises a disc, at least one variable-diameter drill bit is fixedly arranged at the bottom of the disc, and each variable-diameter drill bit comprises an inverted U-shaped fixing plate, a second lead screw in transmission connection with the inverted U-shaped fixing plate, a fixing mounting base in transmission connection with the second leadscrew, a expanding push rod fixedly arranged at the bottom of the fixing mounting base and a auger bit body fixedly connected to the expanding push rod. According to the mechanical arm, the problems that an existing earth auger for digging a pit for a power grid pole cannot change the diameter, drill bits with different diameters are required to be arranged for different pit diameters, and the pitdigging efficiency is low can be solved.

Owner:GUIGANG POWER SUPPLY BUREAU OF GUANGXI POWER GRID CO LTD

Pipeline trenchless pneumatic dumping system and working method thereof

The invention discloses a pipeline trenchless pneumatic dumping system and a working method thereof. The system comprises a high-pressure air blower, and a feeding controller, a reducing pipe, a mixer, a conveying pipe, a gas-solid separator and a solid collector which are sequentially connected along a soil treatment flow direction. The system is small in occupied area, free of environment pollution, continuous in operation, high in unearthing efficiency and high in automation degree.

Owner:中冶南方城市建设工程技术有限公司 +1

Device for bridge construction

ActiveCN107399006AImprove work efficiencyEasy to operateCement mixing apparatusEngineeringBuilding construction

The invention discloses a device for bridge construction. The device comprises a base and a concrete box; a box groove is formed in the tail end of the top of the right side of the base; the concrete box is arranged in the box groove and is fixedly connected with the box groove; a hopper is arranged at the top of the concrete box; a mixing cavity is formed in the part, below the bottom of the hopper, of the concrete box; a soil discharge port extending downwards is formed in the inner bottom wall of the left side of the mixing cavity; a batching cavity extending rightwards penetrates through the extending tail end of the bottom of the soil discharge port; a first conveying and guide cavity is formed in the part, below the middle of the mixing cavity, of the concrete box; a rotating shaft sleeve extending vertically is connected with the interior, between the first conveying and guide cavity and the mixing cavity, of the concrete box in a rotary matching manner; the extending tail end of the top of the rotating shaft sleeve stretches into the mixing cavity; and blocking connecting plates are fixedly arranged on the outer surface of the left side, stretching into the mixing cavity, of the rotating shaft sleeve. The device is simple in structure and convenient to operate, the time and labor are saved during use, the soil discharge effect is improved, and the workload of operation personnel is reduced.

Owner:乐科工业设备有限公司

A soil remediation device that can precisely control the feeding efficiency

ActiveCN108160695BPrecise control of feeding efficiencySave storage spaceRotary stirring mixersTransportation and packagingSoil remediationFrequency conversion

Owner:ANHUI HEKUANG MACHINERY

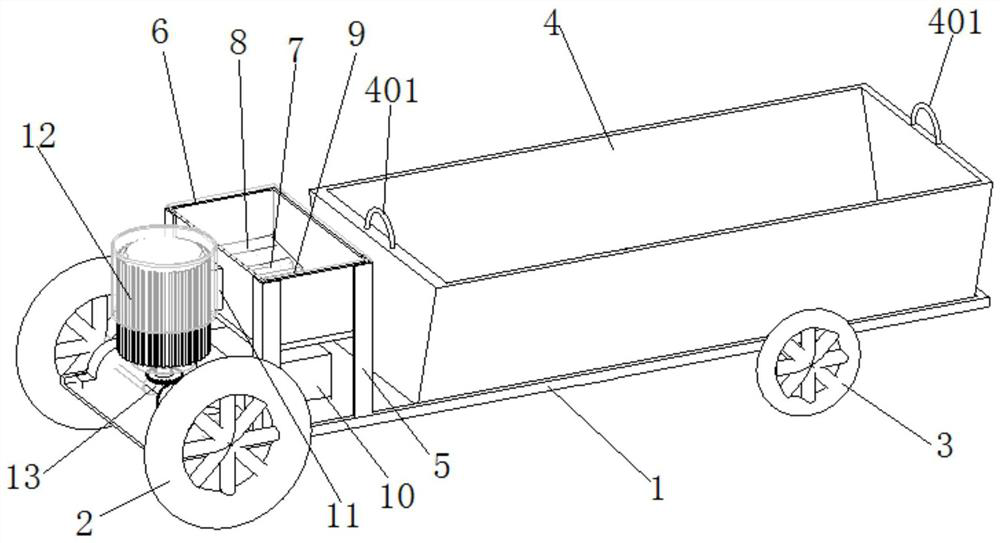

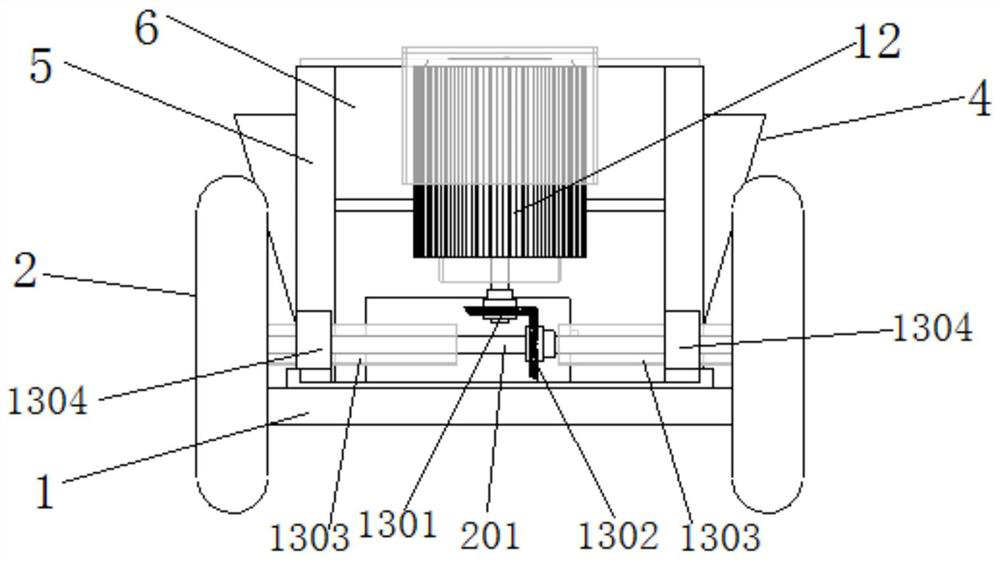

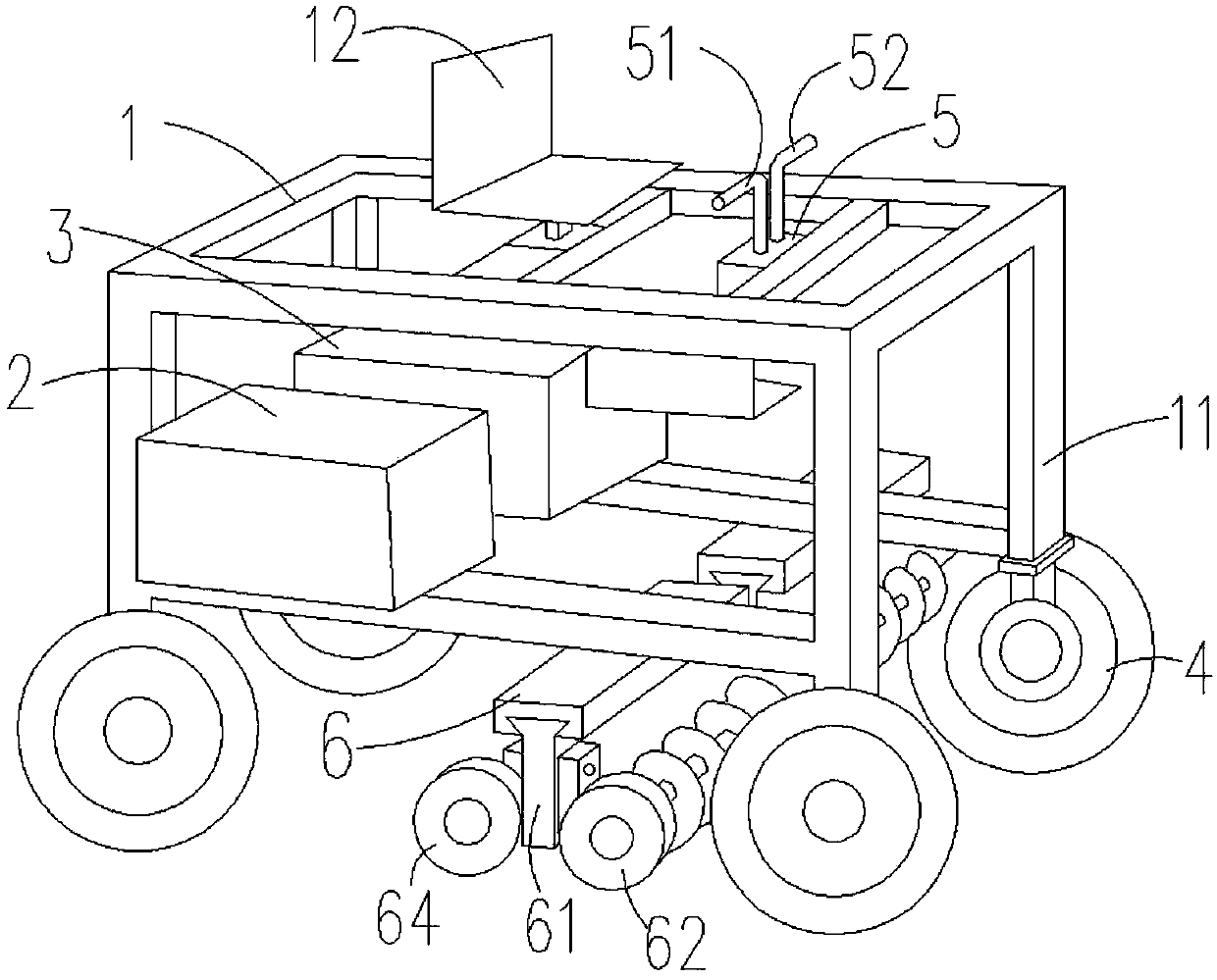

Manual pipe jacking unearthing trolley

PendingCN114644066AImprove unearthed efficiencyReduce labor intensity and job difficultyElectric propulsion mountingVehiclesStructural engineeringWheel and axle

The manual pipe jacking unearthing trolley comprises a trolley body bearing frame, a driving wheel and a driven wheel are arranged on the two sides of the trolley body bearing frame respectively, a cargo bucket is arranged on the trolley body bearing frame, and a control box is further installed on the trolley body bearing frame through a plurality of main supports; a driving device is installed on the outer side wall of the control box, and the output end of the driving device is connected with a wheel shaft of the driving wheel through a transmission device. A storage battery is further arranged below the control box and detachably installed on the vehicle body bearing frame through a plurality of clamping pieces. According to the manual pipe-jacking unearthed trolley, remote control of the trolley can be achieved, operation can be conducted in jacking pipes with different pipe diameters, muck is transferred out, the pipe-jacking unearthed efficiency is improved, the operation difficulty and labor intensity of manual traction are reduced, the labor cost is greatly reduced, and construction safety and the project construction period are guaranteed.

Owner:CHINA CONSTR THIRD ENG BUREAU INSTALLATION ENG CO LTD

A drill bucket type pile digging device

ActiveCN106089081BSimple and fast operationSimple and convenient opening and closingRotary drillingBorehole/well accessoriesCooperative workHydraulic control

The invention relates to pile digging equipment, in particular to a drilling bucket type pile digging device. A rotating motor is connected with a vertically-downward rotating rod through an internally-arranged rotary oil cylinder, the lower end of the rotating rod is connected with a drilling bucket, a drill pipe which vertically penetrates through the drilling bucket is arranged in the drilling bucket, the upper end of the drill pipe is connected with the lower end of the rotating rod, the lower end of the drill pipe extends to the bottom of the drilling bucket, the lower end of the drill pipe is fixed to the inner wall of the drilling bucket through a fixing cross rod, the edge of the lower end of the inner wall of the drilling bucket is connected with two soil drilling blades in a hinged mode, the side edge of each soil drilling blade is provided with a clamping hole, and the lower end of the drill pipe is provided with a clamping control mechanism matched with the clamping holes. According to the drilling bucket type pile digging device, through scientific and reasonable structural connection, opening and closing of a drilling bucket opening can be easily and conveniently controlled through hydraulic control, therefore, the piling and soil digging efficiency is high, and the effect is good; in addition, the device can be controlled by a single person without needing cooperative work of many persons, the construction cost is reduced while the efficiency is improved, and a wide market prospect and the popularization significance are achieved.

Owner:李润

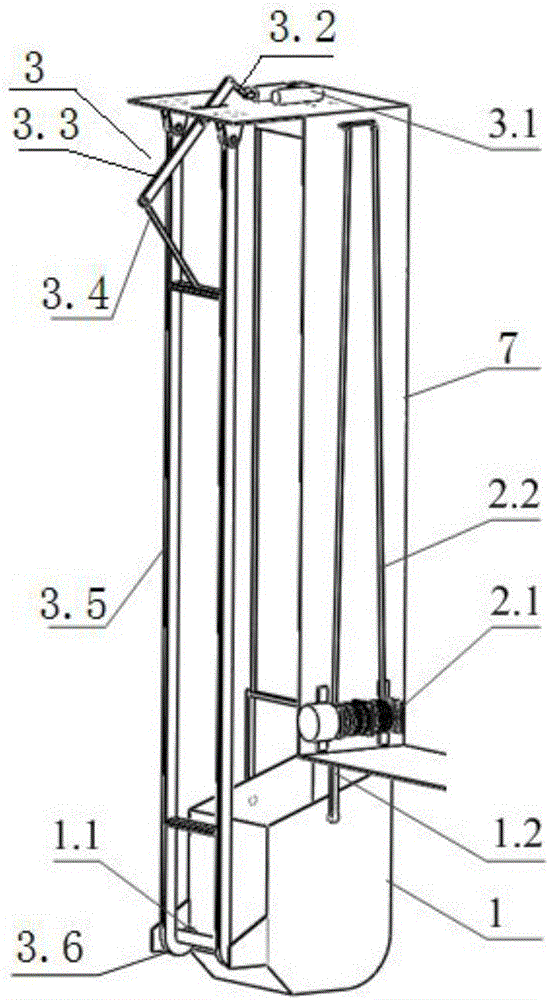

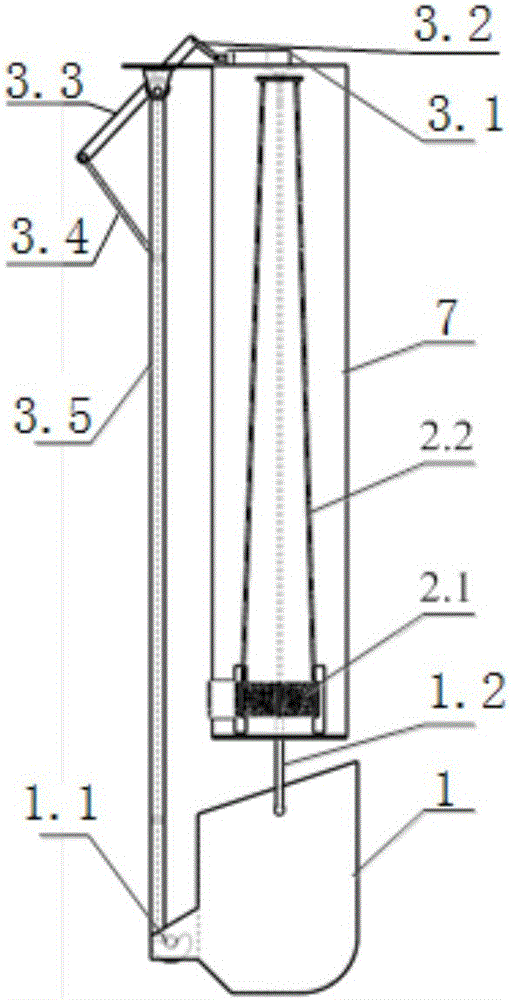

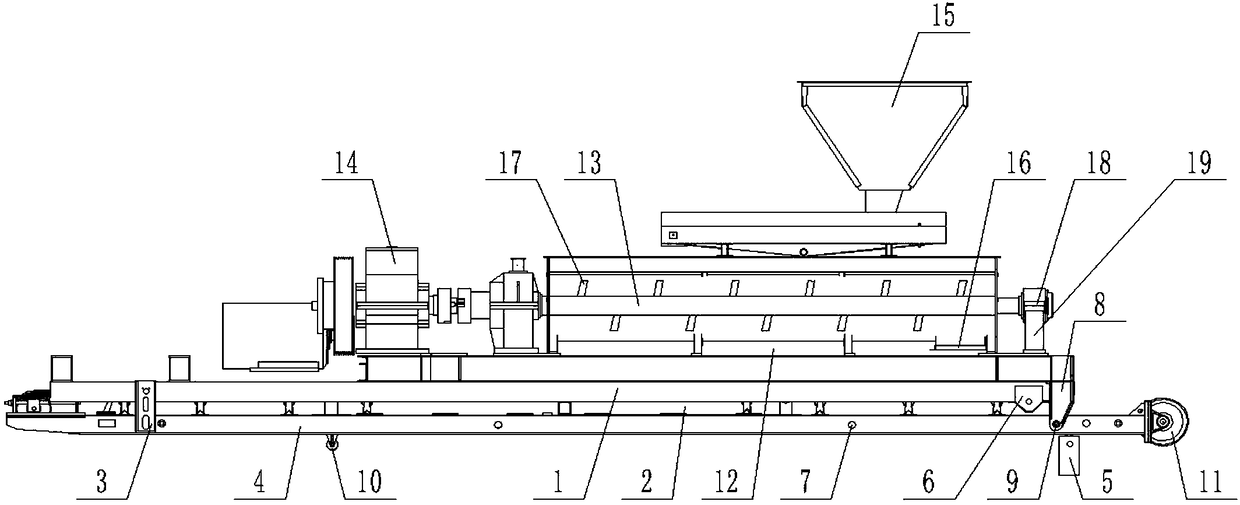

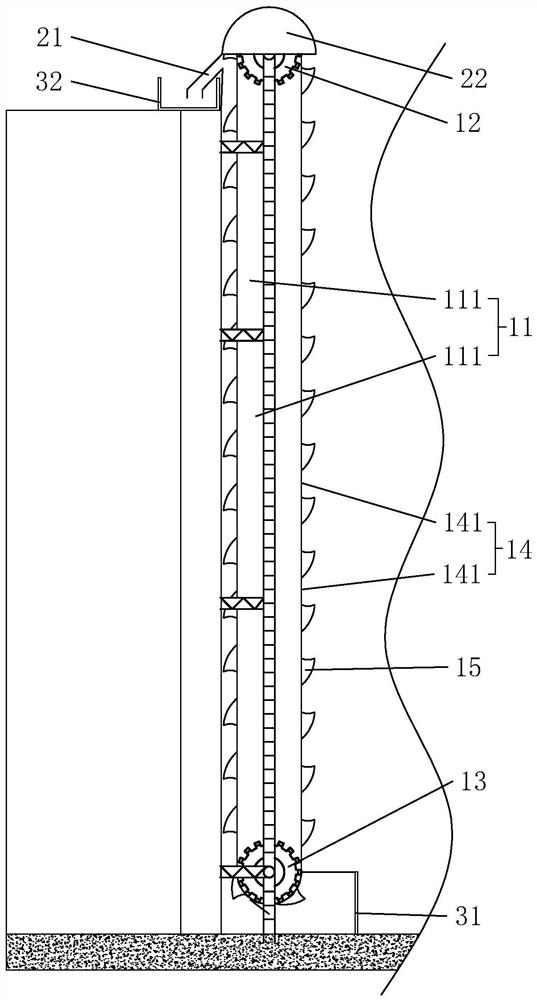

Rapid soil discharging system for ultra-deep foundation pit

InactiveCN113089676AImprove unearthed efficiencySmall footprintExcavationsLoad-engaging elementsSprocketEnvironmental geology

The invention relates to a rapid soil discharging system for an ultra-deep foundation pit, and relates to the field of foundation pit soil discharging in engineering construction. The rapid soil discharging system comprises a supporting frame installed in the foundation pit, a driving chain wheel, a driven chain wheel, a chain wound around the driving chain wheel and the driven chain wheel, a plurality of hoppers fixed to the chain and a power part installed on the supporting frame, wherein the driving chain wheel and the driven chain wheel are rotationally connected to the supporting frame; and the bottom of the supporting frame is installed at the bottom of the foundation pit, the side end of the supporting frame is installed on the inner wall of the foundation pit, the driving chain wheel is located over the driven chain wheel and located above the top of the foundation pit, and the power part is connected with the driving chain wheel to be used for driving the driving chain wheel to rotate. The soil discharging efficiency of the deep foundation pit is improved.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

self-propelled grape excavator

ActiveCN106304858BImprove unearthed efficiencyEasy to operateSoil-working equipmentsAgricultural engineeringFuel tank

The invention discloses a self-propelled grape unearthing machine. The self-propelled grape unearthing machine consists of a frame, a hydraulic power oil tank, a high-pressure oil separator, walking wheels, an operation device and unearthing devices, wherein the frame has a gantry frame structure, and is provided with four supporting legs; hydraulic lifting oil cylinders are arranged on the supporting legs respectively; the front and back parts below the middle part of the frame are smooth and unblocked; hydraulic power oil tank and the high-pressure oil separator are arranged on both sides of the frame; the unearthing devices are symmetrically arranged at the bottoms of both sides of the frame; the walking wheels are arranged at the bottoms of the supporting legs; hydraulic drivers are arranged on the walking wheels. The self-propelled grape unearthing machine has the beneficial effects that high grape unearthing efficiency, convenience in operation and low investment cost are realized, the influences of support columns of a field grape frame are avoided in an operation process, grape branches are not damaged, and the problems of high demand on labor force, low efficiency and high cost in unearthing operation of winter-buried grape are solved.

Owner:宁夏圆润葡萄酒有限公司

A construction method for earthwork excavation of deep foundation pit near the river

The invention discloses a construction method for earth excavation of a deep foundation pit near a river. The construction method is characterized by comprising the following steps that in the construction process for earth excavation of a deep foundation pit project near the river, mechanical excavation for foundation pit construction and hydraulicking for foundation pit construction are combined according to the actual condition of a foundation pit construction site; hydraulicking is adopted for foundation pit construction when the operating space of a traditional mechanical excavation construction machine is limited or the passing time of an earthwork transport vehicle is limited; and meanwhile, earth is converted into mud during hydraulicking for foundation pit construction, and the mud is directly transported away in a waterway transportation way through a mud ship in the river. Influences on the road traffic around the project are avoided, and the transportation time is not limited. By applying the construction method to construction of a construction project, the earth excavation construction efficiency for the deep foundation pit project can be effectively improved, environmental friendliness is achieved, earth excavation noise is lowered, raising dust pollution is reduced, and time and labor are saved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com