Method for setting double-triple soil taking openings by reverse construction method

A reverse method and borrow port technology, which is applied in the field of setting up double and triple borrow ports in reverse method, can solve the problems of difficult excavation, low excavation efficiency, and reduced excavation efficiency, etc., so as to avoid three-dimensional cross construction and shorten excavation. The effect of increasing the excavation time and improving the excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

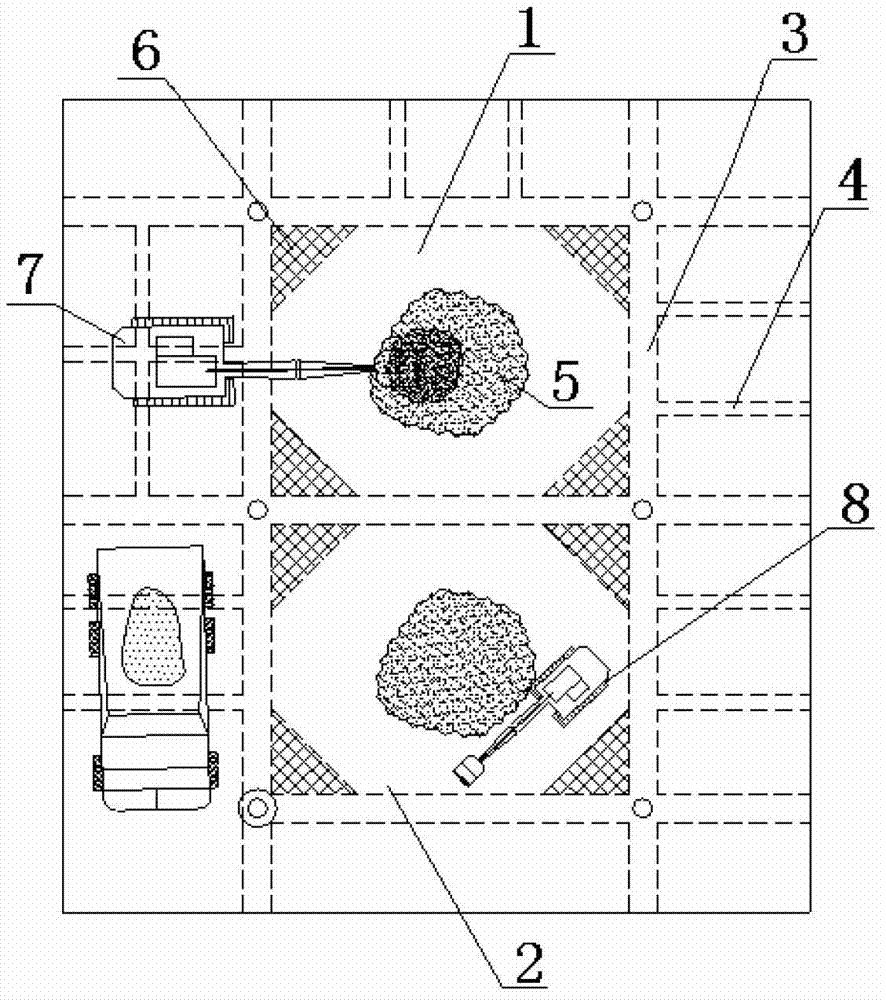

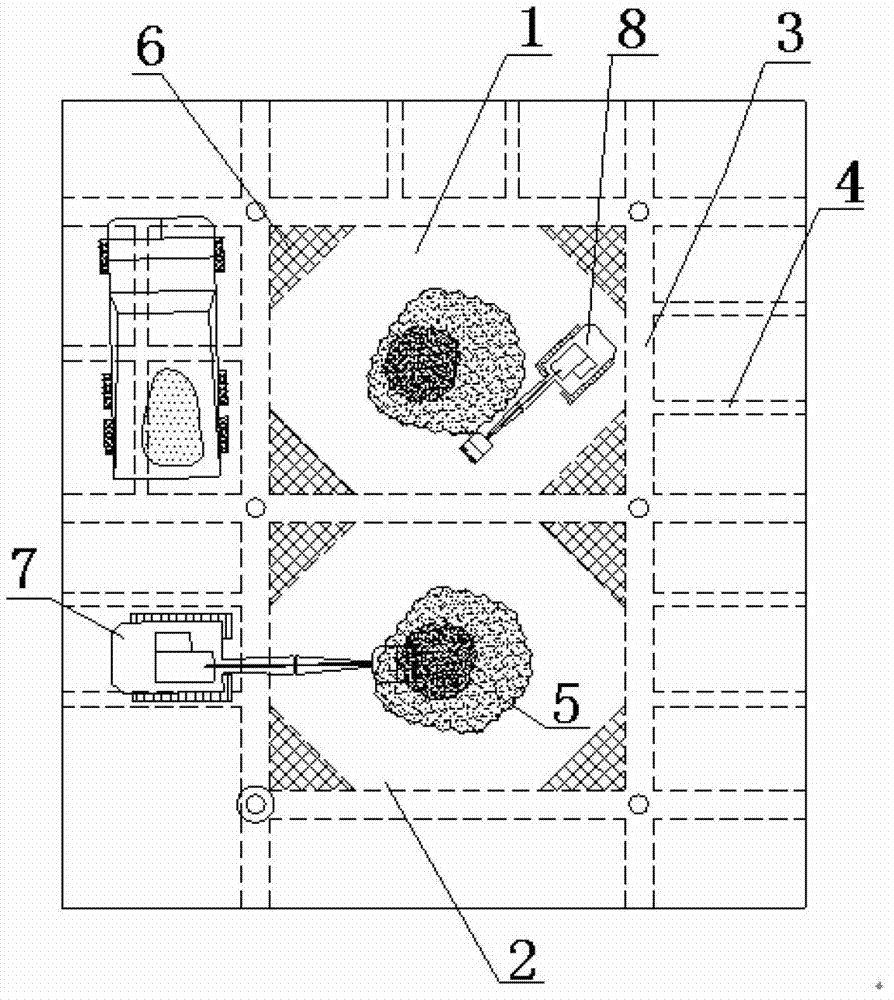

[0015] Example: The excavation area of the podium area of a certain project is more than 23,000 m2, and there are five underground floors. The reverse method is used for construction. The average excavation depth is more than 27m, and the total earthwork is nearly 600,000 m3. Moreover, the construction period of the entire podium basement is relatively tight. . Considering the tight construction period and large amount of earthwork of the reverse method in the basement of the podium, on the premise of ensuring the safety and stability of the foundation pit of the podium, a total of 18 soil intakes were set up in the podium structure from top to bottom, with a total area of 3,000 square meters. more than m2, of which soil intakes-1, soil intakes-5~18 are double and triple soil intakes, such as soil intake-17, soil intake-17 uses the car ramp structure floor missing, in the direction of the horizontal axis Temporary beams are arranged, and the soil intake is calculated thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com