Foundation pit soil moving-out device

A technology for foundation pits and installation gaps, which is applied in foundation structure engineering, earth movers/excavators, excavation, etc., and can solve problems such as occupying tower cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

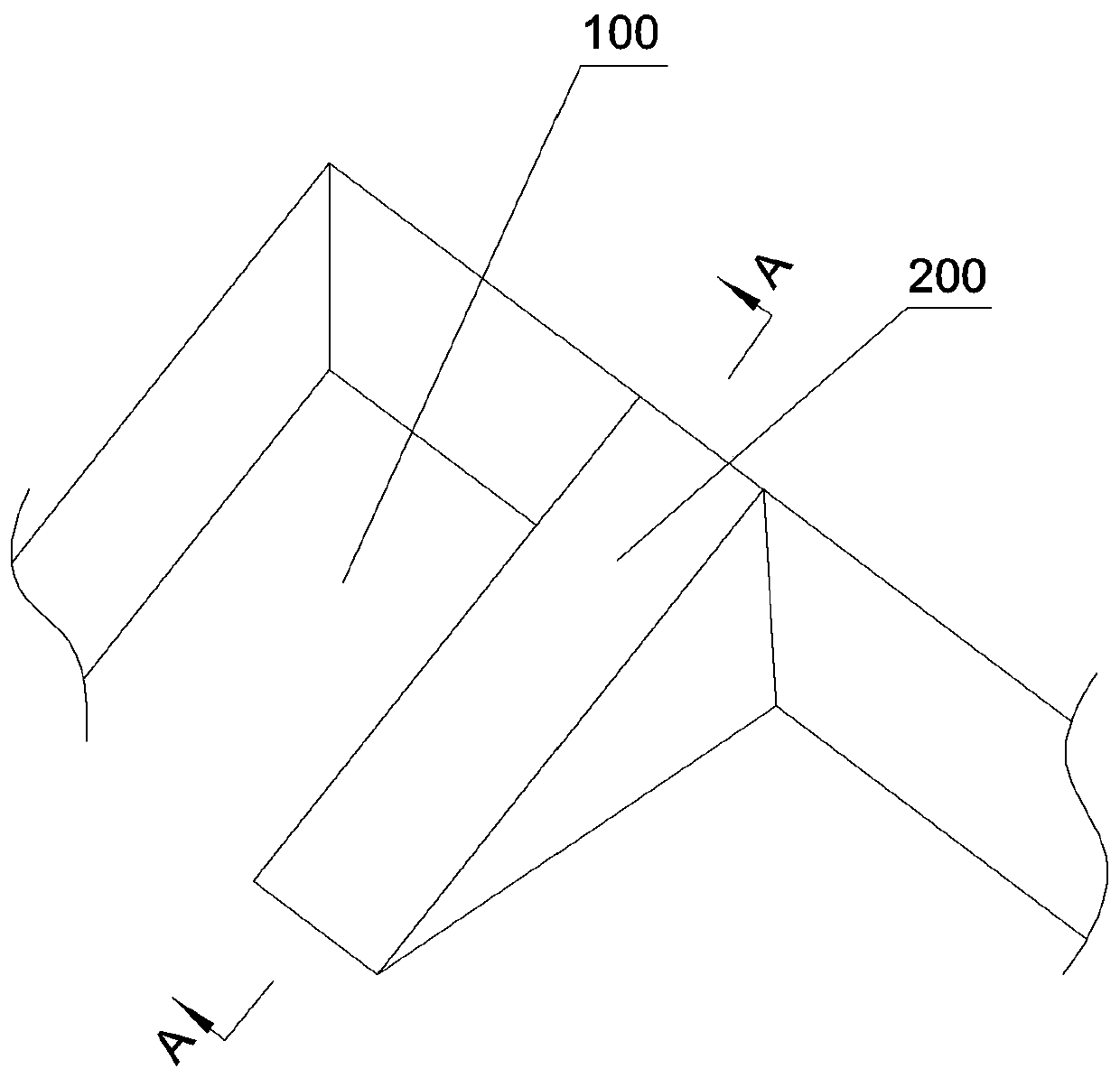

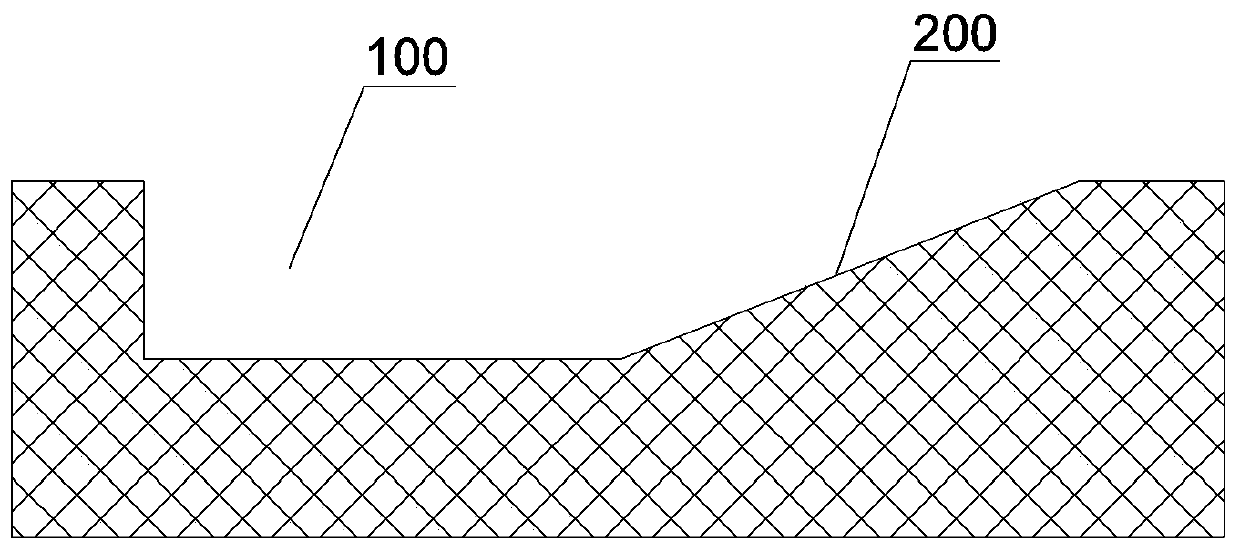

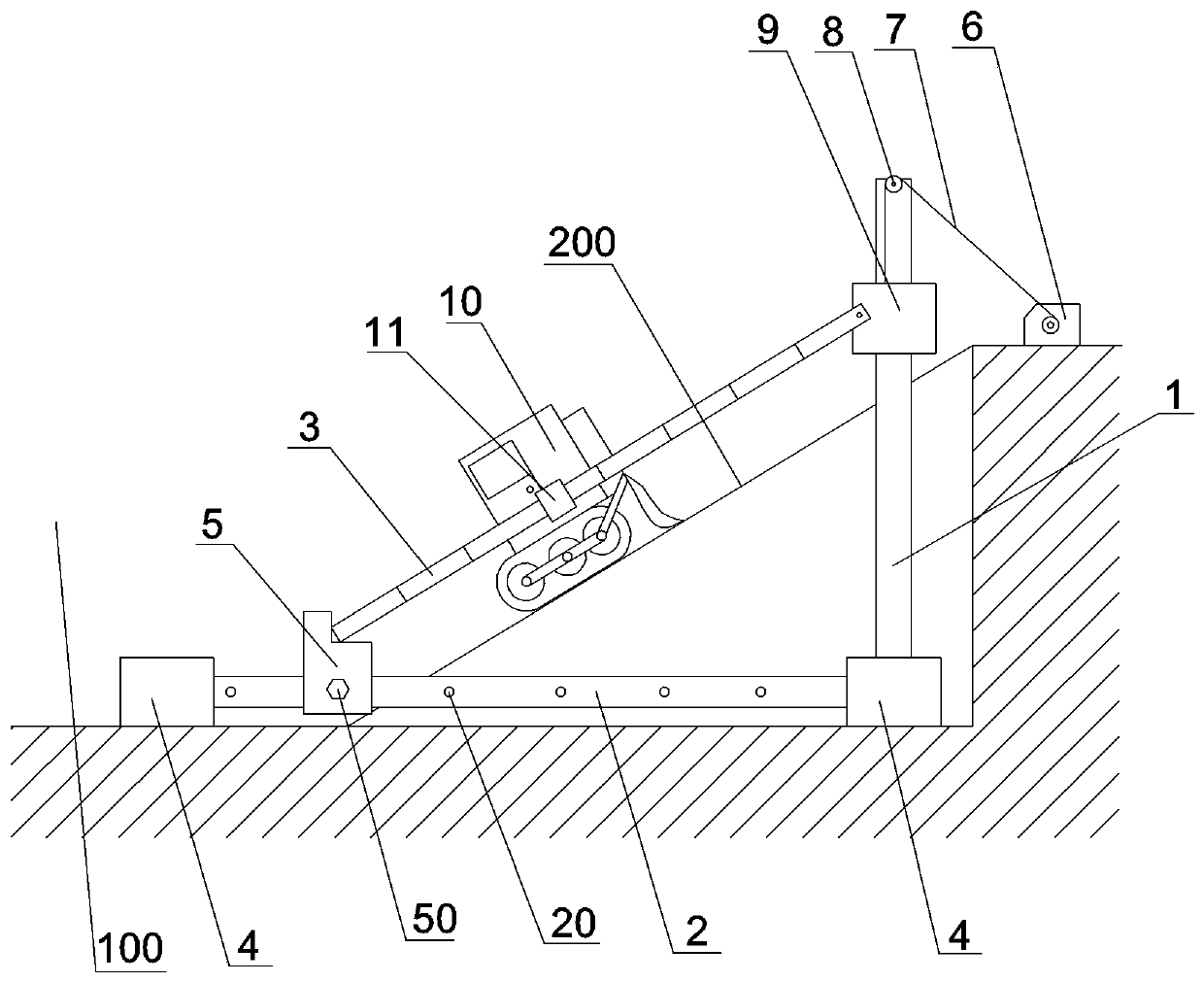

[0030] like image 3 As shown, the foundation pit excavation device of this embodiment includes an excavation mechanism arranged above the foundation pit ramp 200 and two support and guide mechanisms respectively arranged on both sides of the foundation pit ramp 200 .

[0031] The support guide mechanism comprises a vertical support rod 1, a horizontal support rod 2 and an inclined guide rod 3, and the horizontal support rod 2 is fixed on the side bottom of the foundation pit ramp 200 by two fixed piles 4 inserted into the bottom of the foundation pit 100, vertically The bottom of the support rod 1 is fixed on the fixed pile 4 close to the wall of the foundation pit, and the vertical support rod 1 is located at the top side of the foundation pit ramp 200 . The inclined guide rod 3 is parallel to the upper surface of the foundation pit ramp 200, and the vertical support rod 1 is slidably connected with a moving sleeve 9, and the moving sleeve 9 and the top of the inclined guide...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the splicing method of the segments is plug-in, that is, the end face of one segment is fixed with an insertion rod, and the end face of the other segment is fixed with a socket, and the insertion rod is inserted into the socket , to achieve splicing of adjacent segments.

Embodiment 3

[0041] The difference between this embodiment and the first embodiment is that the bulldozer is also equipped with a rake tine type soil loosening part, which is rotatably connected to the bulldozer, and the locking between the soil loosening part and the bulldozer is realized through buckles. When the bulldozer walks down along the inclined guide bar 3, the loosening parts are put down, and the loosening parts loosen the soil on the slope; Loose soil for bulldozing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com