Push pipe construction method and push pipe device

A construction method and pipe jacking technology, applied in pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve problems affecting the construction efficiency of pipe jacking workers, so as to improve excavation efficiency, pipe jacking efficiency, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

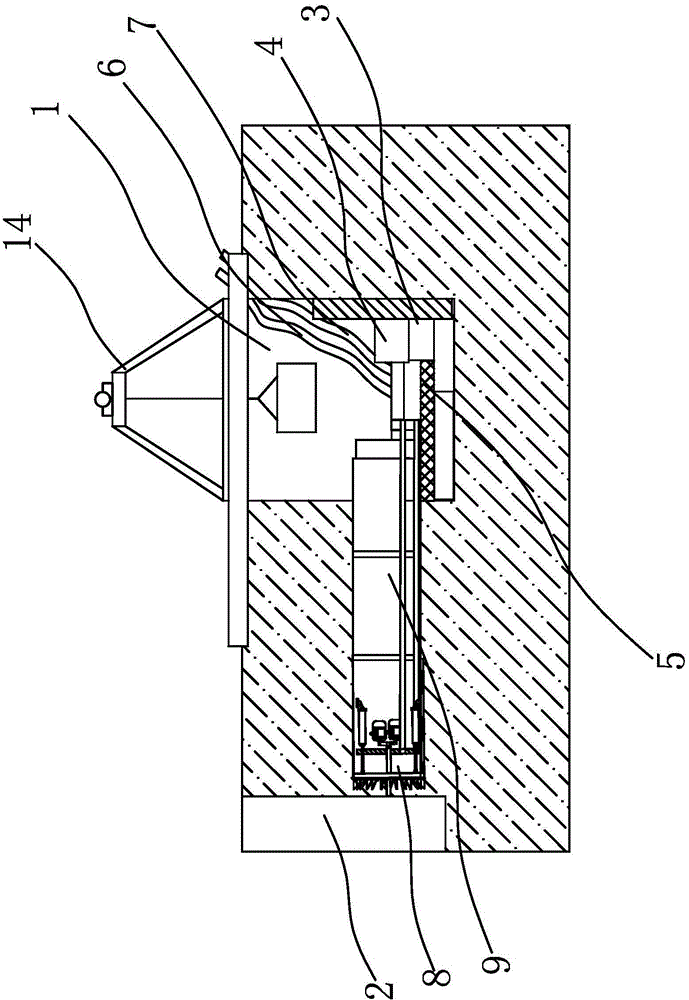

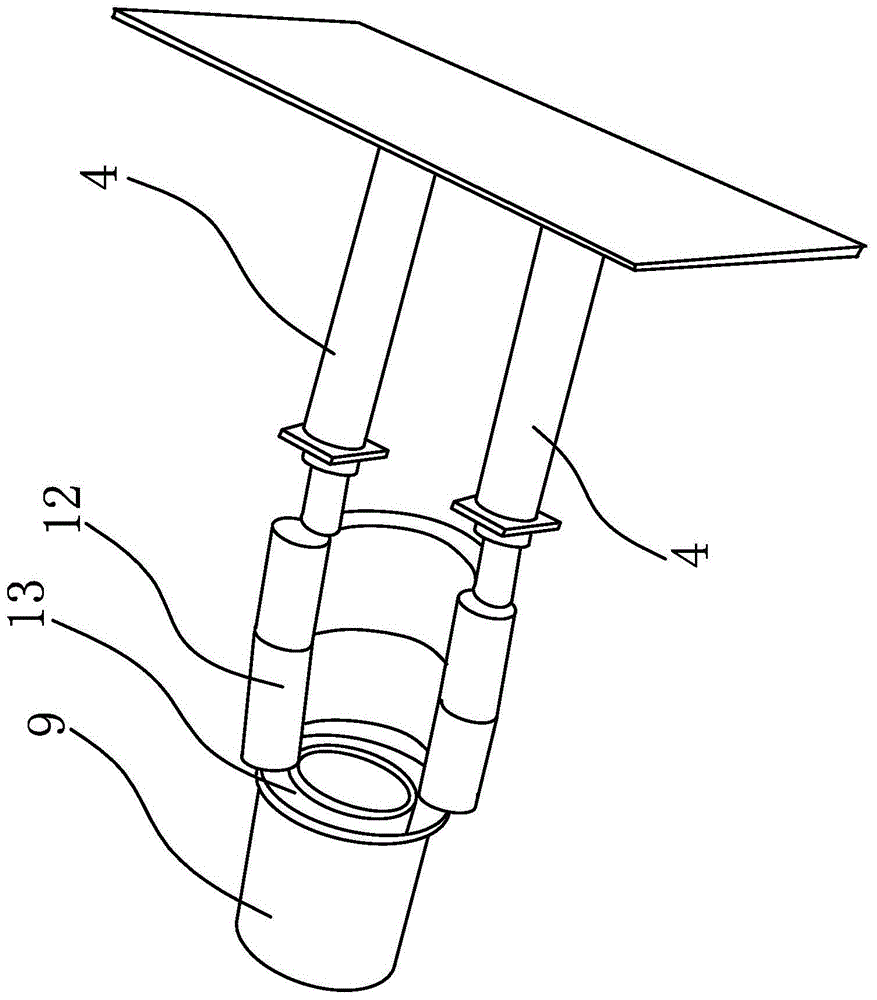

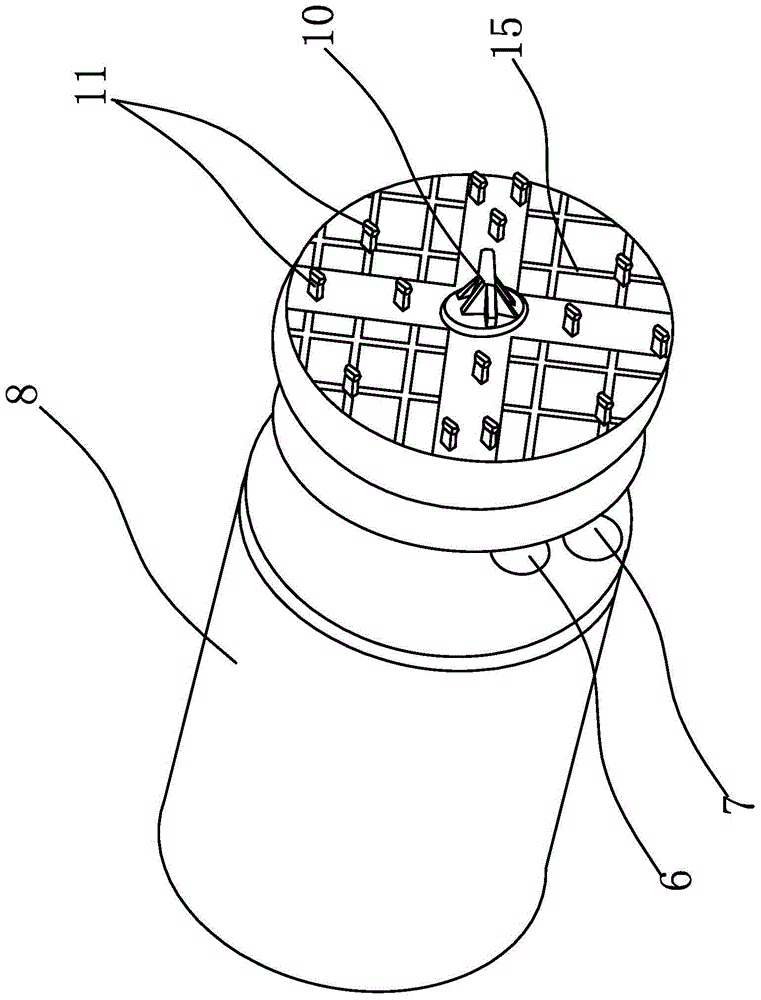

[0033] Such as Figure 1 to Figure 3 As shown, the pipe jacking device includes a hydraulic jack 4, a jack bracket 3, a slide rail 5 and a pipe jacking drill bit 8, the jack 4 is arranged on the jack bracket 3, the pipe jacking drill bit 8 is arranged on the slide rail 5, and the expansion and contraction of the jack 4 The rod faces the pipe jacking bit 8, an annular backrest 13 is arranged between the jack 4 and the pipe jacking bit 8, and the annular backrest 13 is attached to the end of the pipe jacking bit 8, and the pipe jacking device also includes several semi-dome plates that can extend the stroke of the jack 4 12. The diameter of the inner end of the annular backrest 13 is greater than the diameter of the outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com