Drilling bucket type pile digging device

A drill bucket and drill pipe technology, which is applied to sheet pile walls, earth-moving drilling, drilling equipment, etc., can solve the problems of difficulty in removing the ground, time-consuming and laborious, and inconvenient transportation, and achieve the effect of fixing and stabilizing the casing of the oil cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

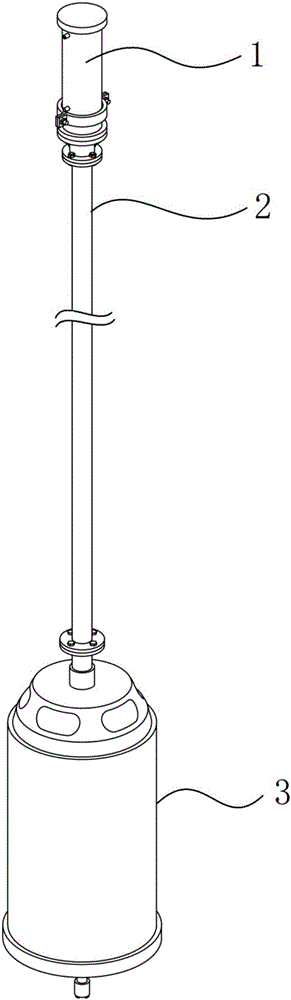

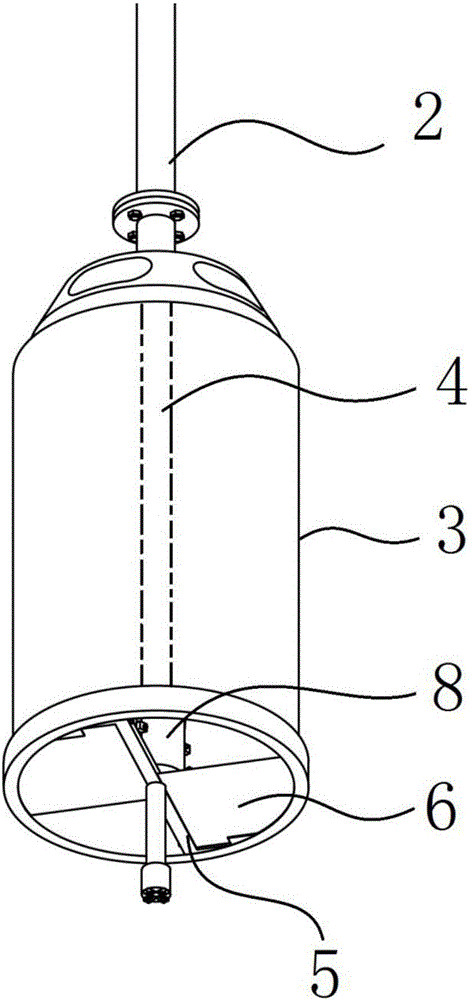

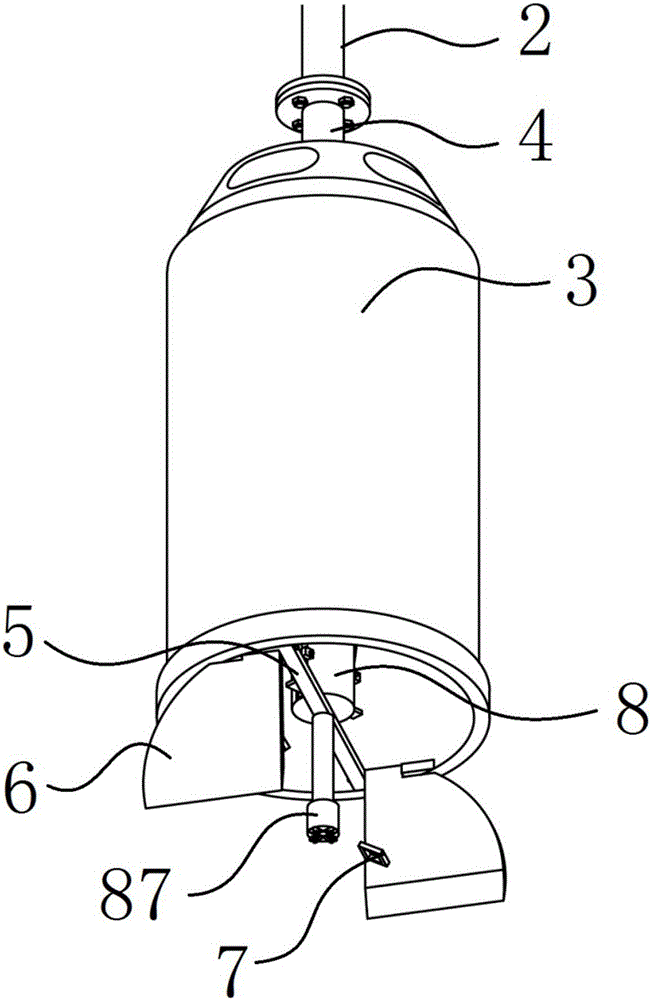

[0036]Embodiment: a drill bucket type pile digging device, including a power excavator 90 that provides power output, a telescopic arm 91 connected to the power excavator 90, a turntable 92 installed on the end of the telescopic arm 91, and the turntable 92 can To provide clockwise or counterclockwise rotation power, the power excavator 90 can be an excavator, a small excavator, or a locomotive that can provide hydraulic power and can be lifted. The rotary machine 92 can be used in combination with a reducer and a transmission. The rotary machine 92 is connected to the vertically downward rotating rod 2 through the built-in rotary oil cylinder 1, and the lower end of the rotating rod 2 is connected with a drilling bucket 3. Inside the drilling bucket 3, there is a drill pipe 4 that runs through the top and bottom of the drilling bucket 3. The drilling pipe 4 The upper end is connected to the rotating rod 2, and the lower end extends to the bottom of the drilling bucket 3. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com