Construction system and method of pipe gallery with integral prefabricated pipe joint and internal partition

An integral prefabricated, inner clapboard technology, used in artificial islands, earthwork drilling, water conservancy projects, etc., can solve the problems of poor integrity of pipe joints and inner clapboards, difficult on-site assembly or cast-in-place construction, etc. Unearthed efficiency, fast construction speed and good integrity of the pipe gallery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

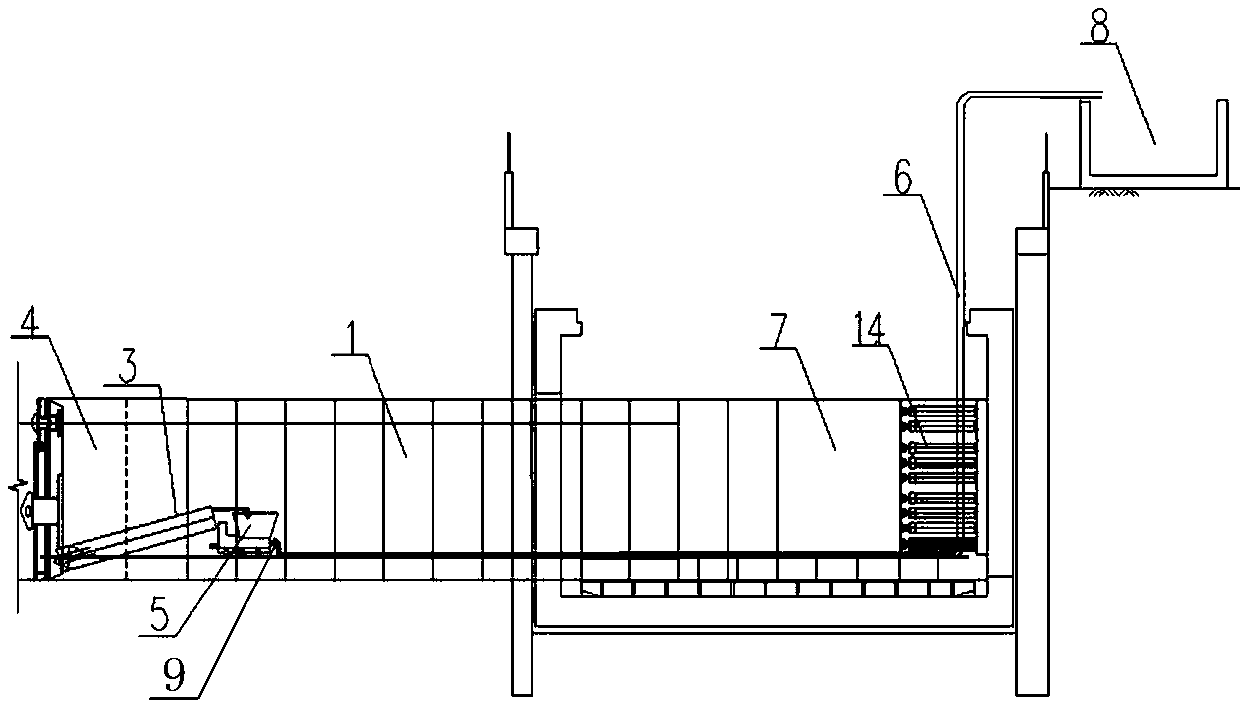

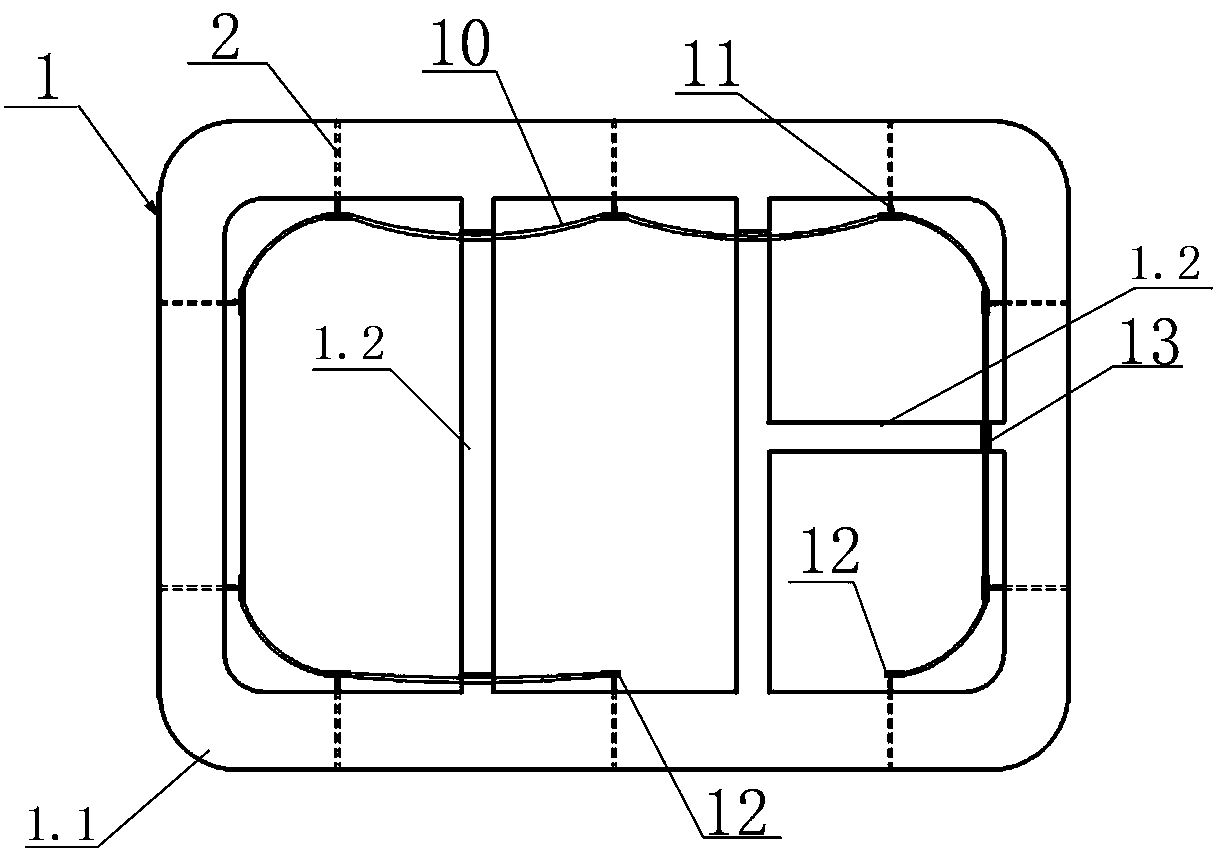

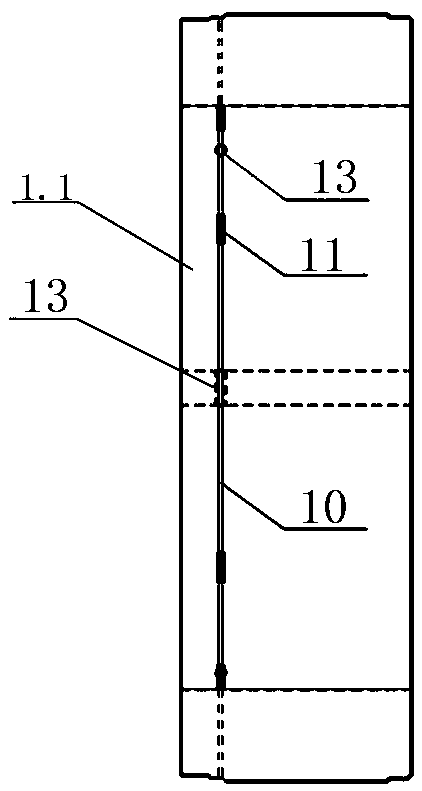

[0033] Such as Figure 1-5 As shown, the construction system of this kind of pipe gallery with integral prefabrication of pipe joints and internal partitions, pipe gallery 1 includes pipe joints 1.1 and internal partitions 1.2, and pipe joints 1.1 and internal partitions 1.2 are integrally prefabricated; the pipe joints 1. On the side wall of 1.1, grouting holes 2 are arranged at intervals along the circumferential direction; the construction system includes an excavation system, an anti-friction grouting pipe system and a jacking system; the excavation system includes a screw excavator 3 and a supporting pump 5 and the pump pipe 6; the screw excavator 3 is arranged in the tunnel 4 to output the muck cut in front of the pipe gallery 1; the supporting pump 5 is connected to the outlet of the screw excavator 3; the pump pipe One end of 6 is connected to the support pump 5, and the other end of the pump pipe 6 passes through the pipe gallery 1 and extends into the muck pool 8 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com