Novel injection molding machine

An injection molding machine, a new type of technology, applied in the field of injection molding machines, can solve the problems of inconvenient, inconvenient replacement or maintenance, etc., and achieve the effect of improving the efficiency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and specific embodiments.

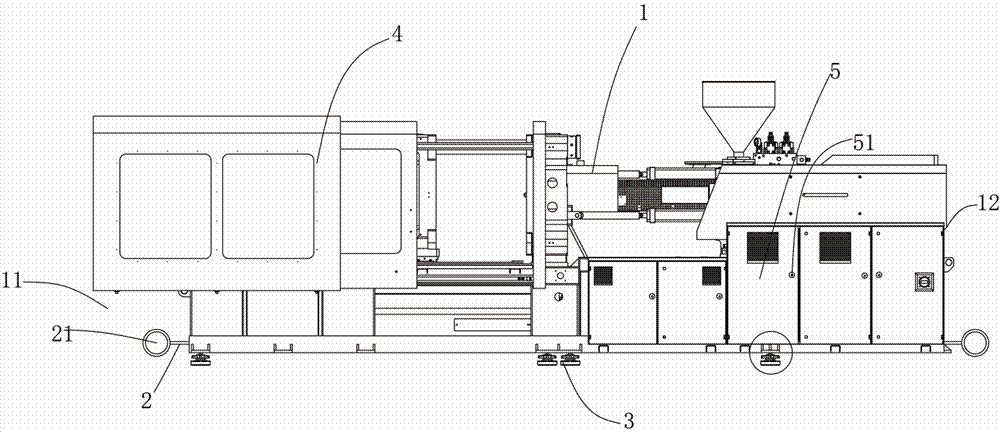

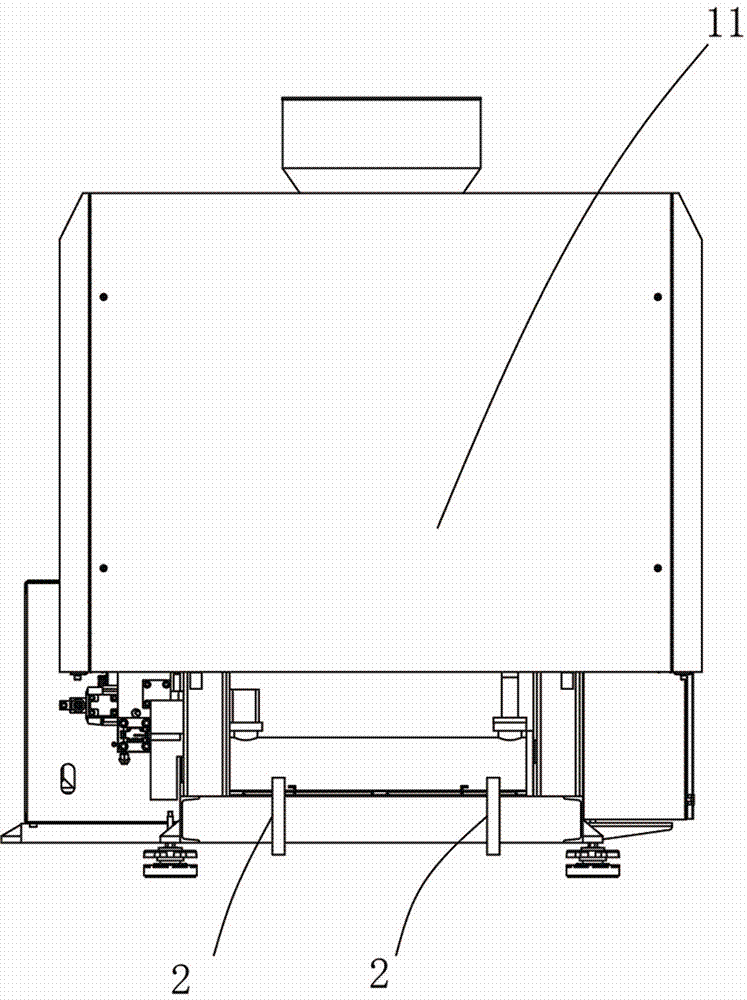

[0016] See Figure 1 to 6 , A new type of injection molding machine, including a body 1, two end faces 11, 12 in the length direction of the body 1 are provided with through holes, each of the end faces 11, 12 is provided with two through holes, each through hole A shaft 2 is connected inside, the end of the shaft 2 is provided with a circular ring 21, and the hook of the crane is buckled into the circular ring. The length of the injection molding machine is very long, but the width is relatively short. Therefore, the crane is easier to maintain the center of gravity by hooking at both ends and not prone to rollover.

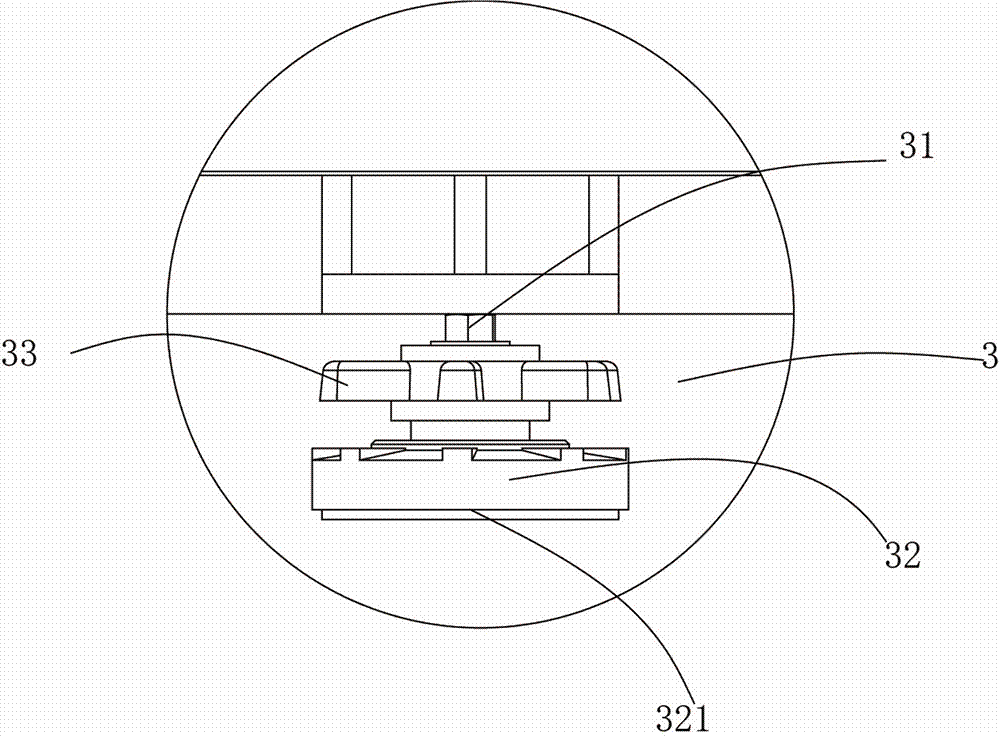

[0017] The bottom of the body 1 is provided with a foot pad 3, the foot pad 3 includes a raised portion 31 connected to the bottom of the body and a sleeve body 32, the raised portion 31 is provided with a thread, the sleeve body 32 Connected to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap