Intelligent wheel speed sensor structure

A wheel speed sensor, intelligent technology, applied in the field of intelligent wheel speed sensor structure, can solve the problems of complex installation of wheel speed sensors, achieve the effect of improving NVH and waterproof performance, strong practicability, and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

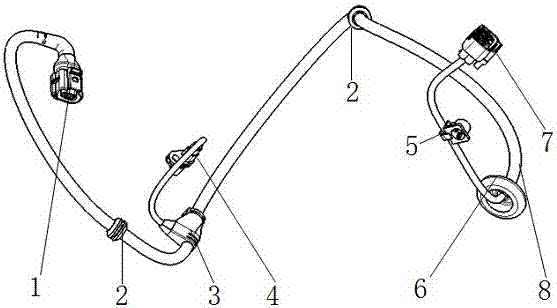

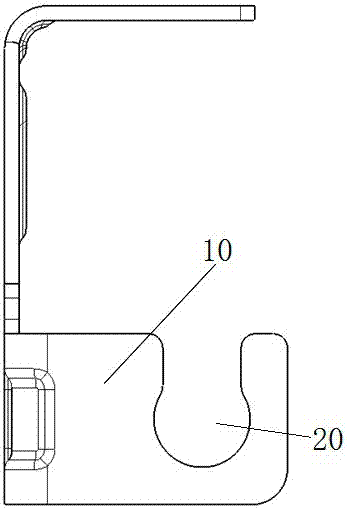

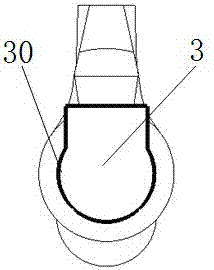

[0027] Figure 1 to Figure 3 An intelligent wheel speed sensor structure is shown, including a PIN plug-in, a branch structure 3, a wheel speed sensor probe 4, a four-PIN plug connector 7 and a wire harness 8; wherein, the PIN plug-in includes a two-PIN plug-in 1 and a four-PIN plug-in connector 7 , the wiring harness 8 is divided into an EPB wiring harness and an intelligent sensor wiring harness, and the two parts are integrated into one; the two-PIN plug-in 1 and the four-PIN plug-in connector 7 are respectively arranged at both ends of the wiring harness 8, and are respectively used to complete their respective functions; further, The wheel speed sensor probe 4 is set on the wire harness 8 through the branch structure 3 to detect the speed of the vehicle; the four-PIN plug connector 7 and the wire harness 8 are integrally formed by injection molding, which can not only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com