Vibration-damping device

一种隔振、安装构件的技术,应用在减振器、减振器-弹簧组合、弹簧/减震器等方向,达到抑制异常噪音、简单结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

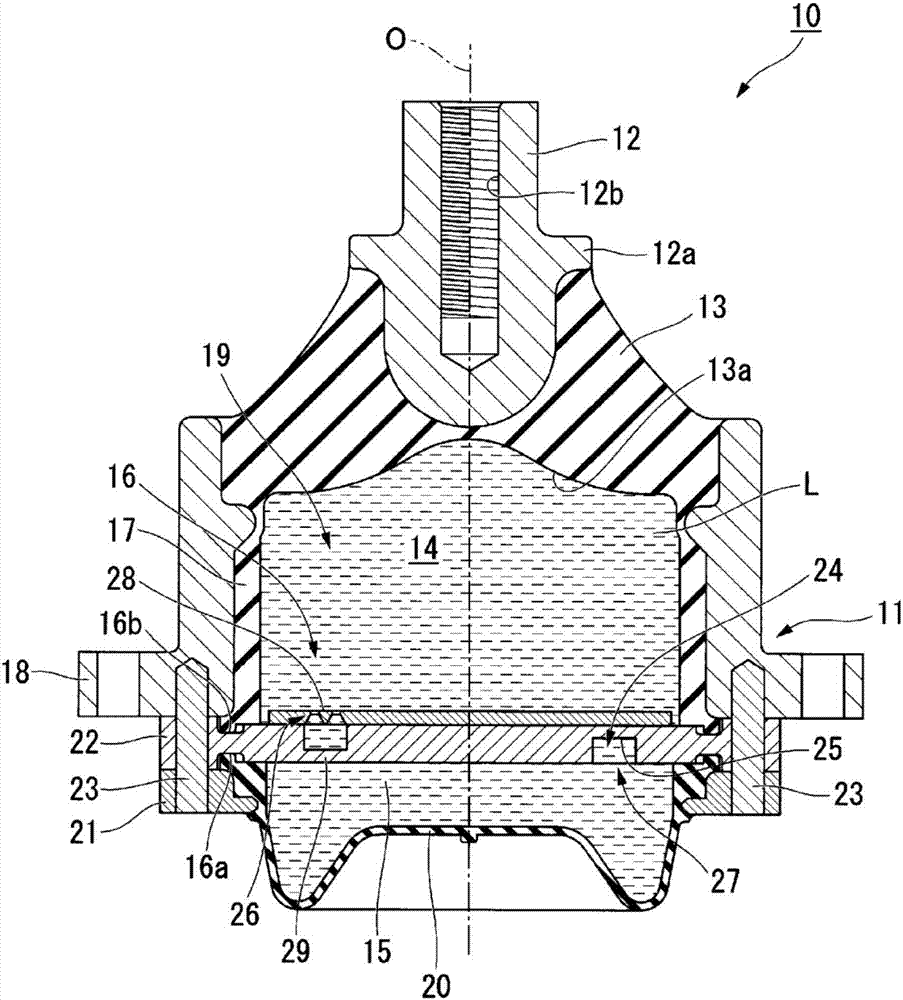

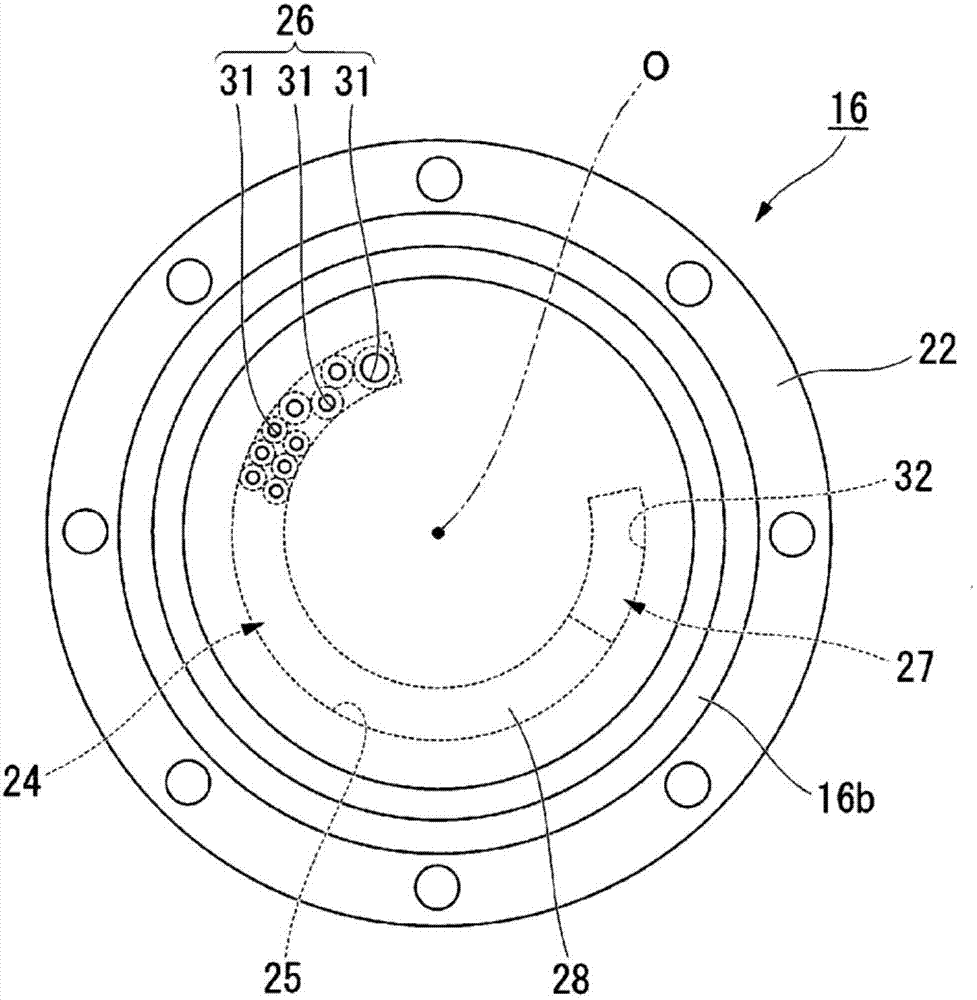

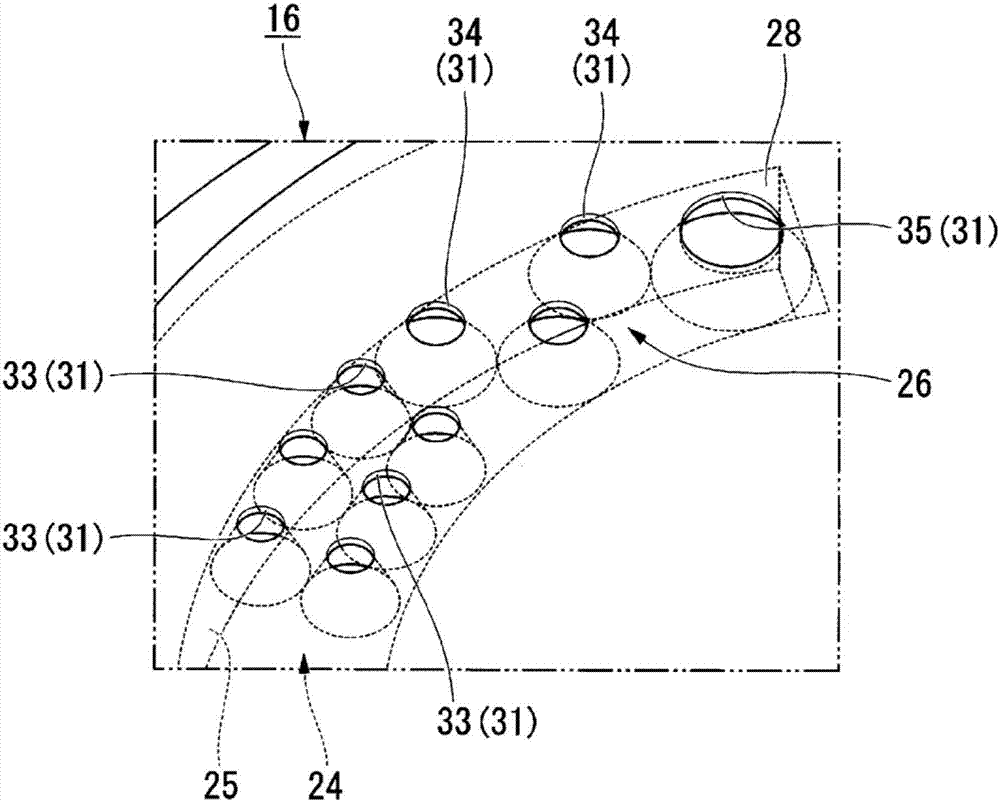

[0028] The following will be based on Figure 1 to Figure 3 Embodiments of the vibration isolation device according to the present invention will be described. Notice, figure 1 The shown reference numeral O (hereinafter simply referred to as "axis center O") denotes the central axis of the vibration isolator 10 (the central axis of the first mounting member 11 which will be described below). In addition, the direction along the axis O is set as "axial direction" (the axial direction of the first attachment member 11 ). In the plan view of the vibration isolator 10 viewed from the axial direction, the direction perpendicular to the axis O is defined as the "radial direction" (the radial direction of the first mounting member 11), and the direction around the axis O is defined as Let it be "circumferential direction" (circumferential direction of the first mounting member 11).

[0029] like figure 1 As shown, the vibration isolation device 10 includes: a cylindrical first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com