A decorative panel cutting device for interior decoration

A technology for cutting devices and decorative panels, applied in the direction of feeding devices, positioning devices, manufacturing tools, etc., can solve the problems of single function of sheet cutting equipment, poor sheet cutting quality, and low sheet cutting efficiency, and achieve wide application range and cutting size Adjustable, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

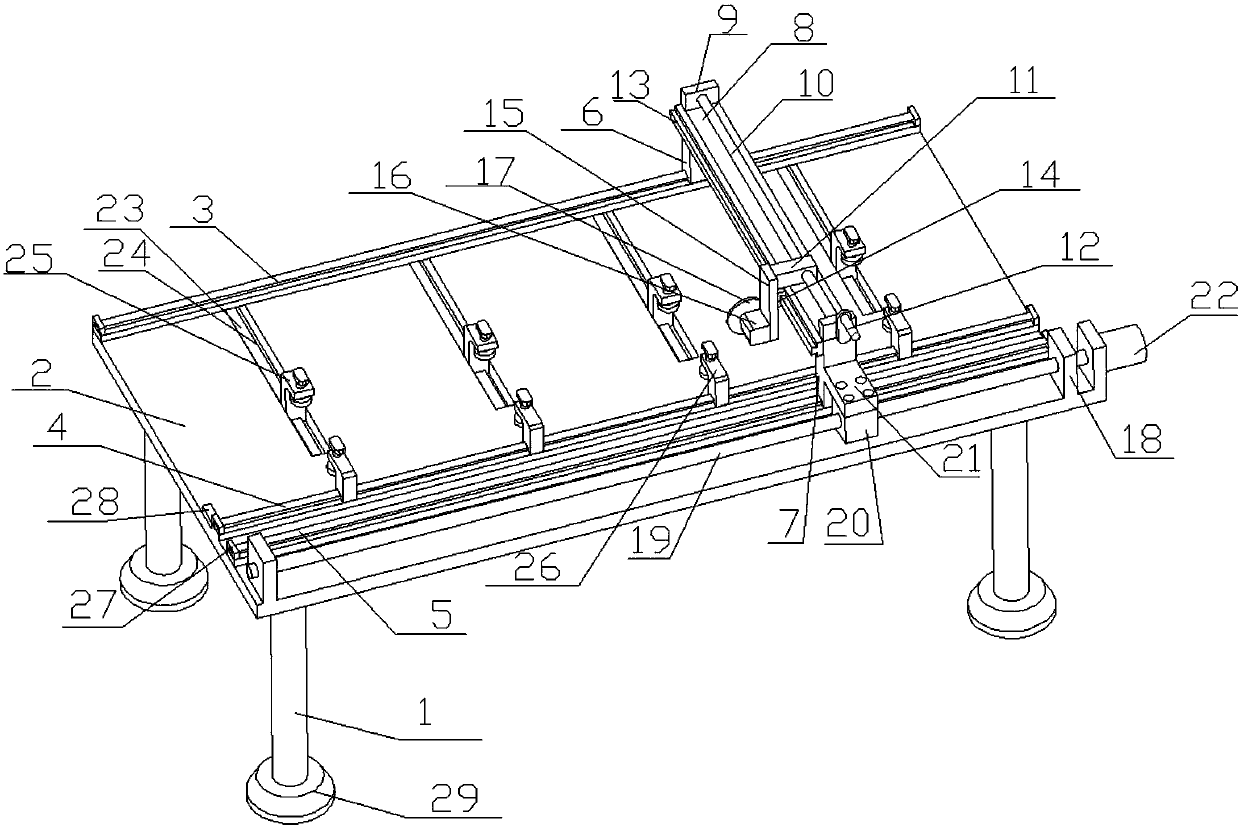

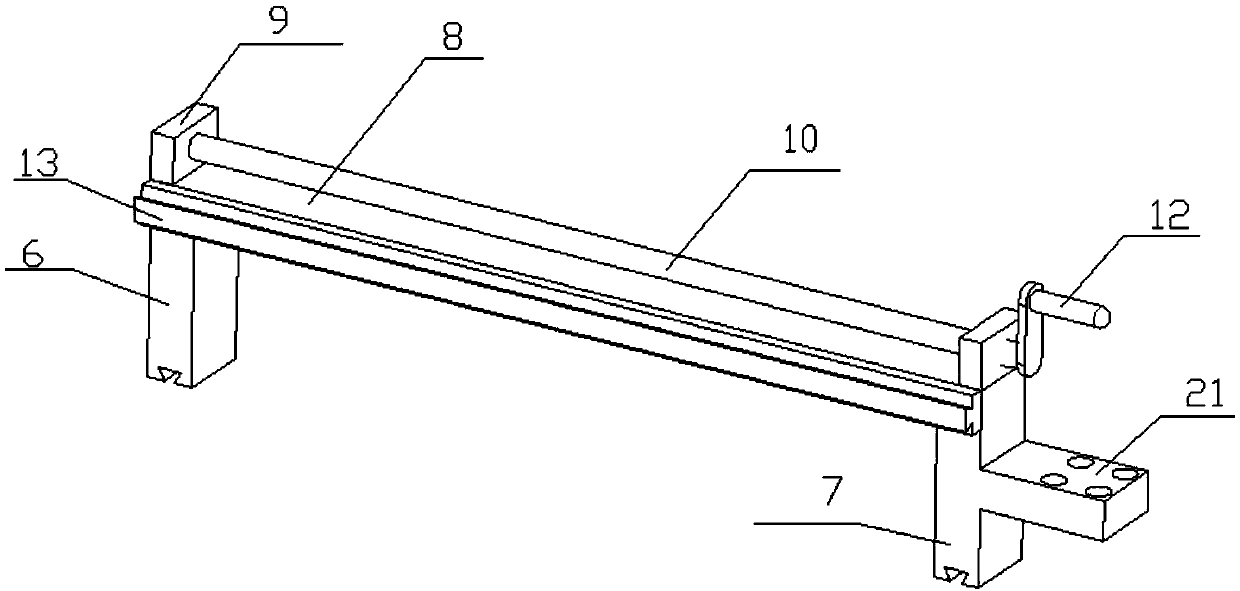

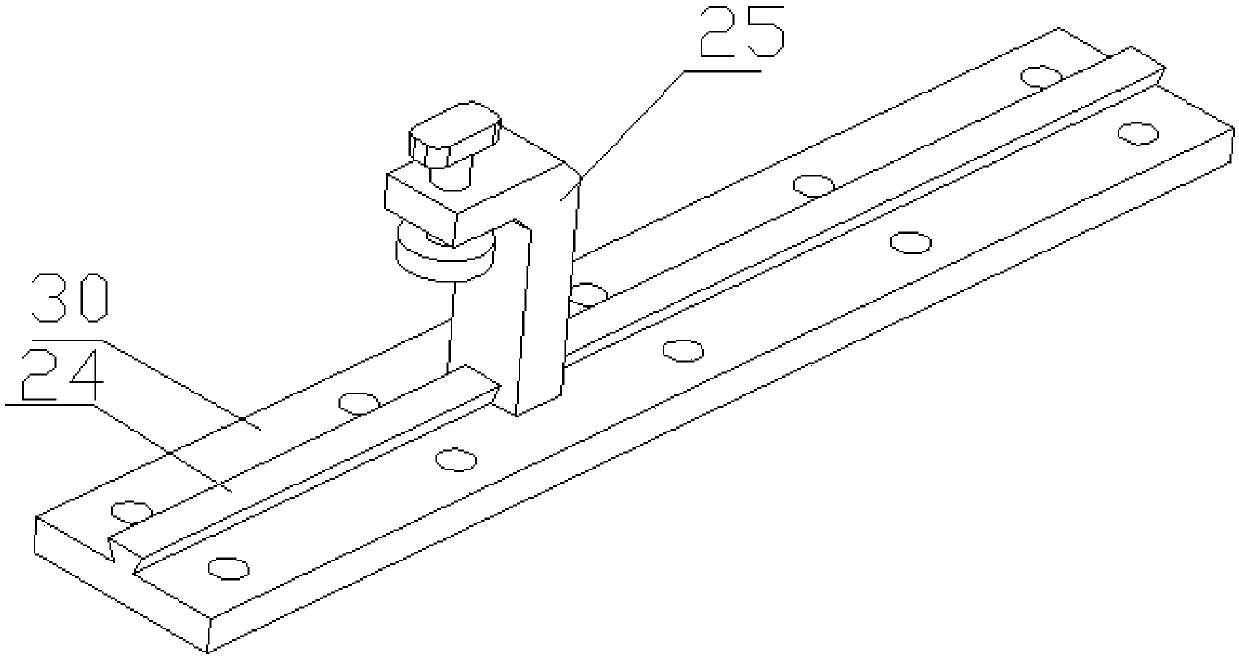

[0034] figure 1 , figure 2 , image 3 and Figure 4 The specific embodiment of the present invention is shown: a decorative board cutting device for interior decoration, including four legs 1 and a workbench 2 arranged on the legs 1, the workbench 2 is provided with first guide rails arranged in parallel 3. The second guide rail 4 and the third guide rail 5, the second guide rail 4 is arranged between the first guide rail 3 and the third guide rail 5, and the first guide rail 3 and the third guide rail 5 are respectively provided with the first The first sliding seat 6 and the third sliding seat 7 that are slidably matched between the guide rail 3 and the third guide rail 5, a connecting plate 8 is arranged between the first sliding seat 6 and the third sliding seat 7, and a connecting plate 8 is provided on the connecting plate 8 There is a cutting motor 16, the position of the cutting motor 16 on the connecting plate 8 is adjustable, the output shaft of the cutting motor...

Embodiment 3

[0038] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The specific embodiment of the present invention is shown: a decorative board cutting device for interior decoration, including four legs 1 and a workbench 2 arranged on the legs 1, the workbench 2 is provided with first guide rails arranged in parallel 3. The second guide rail 4 and the third guide rail 5, the second guide rail 4 is arranged between the first guide rail 3 and the third guide rail 5, and the first guide rail 3 and the third guide rail 5 are respectively provided with the first The first sliding seat 6 and the third sliding seat 7 that are slidably matched between the guide rail 3 and the third guide rail 5, a connecting plate 8 is arranged between the first sliding seat 6 and the third sliding seat 7, and a connecting plate 8 is provided on the connecting plate 8 There is a cutting motor 16, the position of the cutting motor 16 on the connecting plate 8 is adjustable, the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com