Tapered pipe mouth intersecting line cutting device and assembly method

A technology of intersecting line cutting and assembly method, which is applied in the direction of tubular objects, manufacturing tools, and other household appliances, etc., to achieve the effects of easy disassembly and assembly, expanding the scope of application, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and specific embodiments, the present invention will be described in further detail:

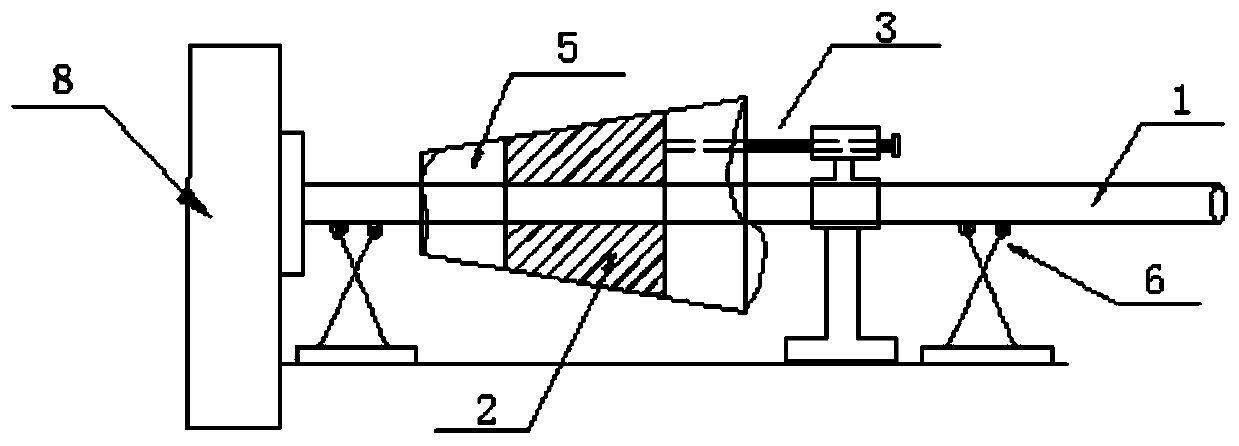

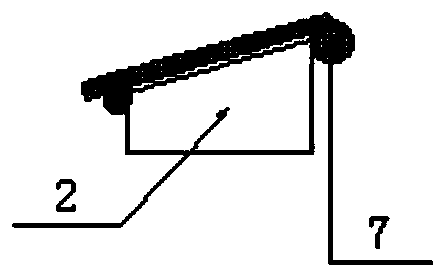

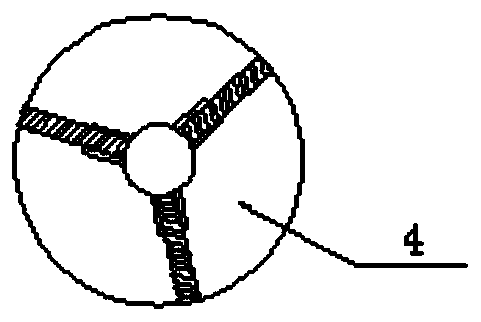

[0021] The cutting device for the intersecting line of the conical pipe orifice shown in the figure includes a straight round pipe 1 with a guide groove, a plurality of right-angled trapezoidal wedges 2 of different sizes, a top-tight screw rod frame 3, and the guide groove 4 is along a straight circle. The tube 1 is arranged axially, the straight round tube 1 is installed on the cutting bracket 6, the right-angled side of the right-angled trapezoidal wedge 2 is installed in the guide groove 4 of the straight round tube 1, and rubber 7 is provided on the oblique side. The wedge 2 is used to fix the conical tube 5 of the corresponding size on the straight round tube 1. The jacking screw frame 3 includes a sleeve base and a jacking screw connected to the sleeve base. The jacking screw is used for jacking. Tighten the right-angled trape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com