A wrench for fastening high-strength bolts

A high-strength bolt and fastening technology, which is applied in the field of wrenches, can solve the problems of reducing the practicality and reducing the fastening stability of bolts, and achieves the effects of improving efficiency, improving safety and practicality, and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

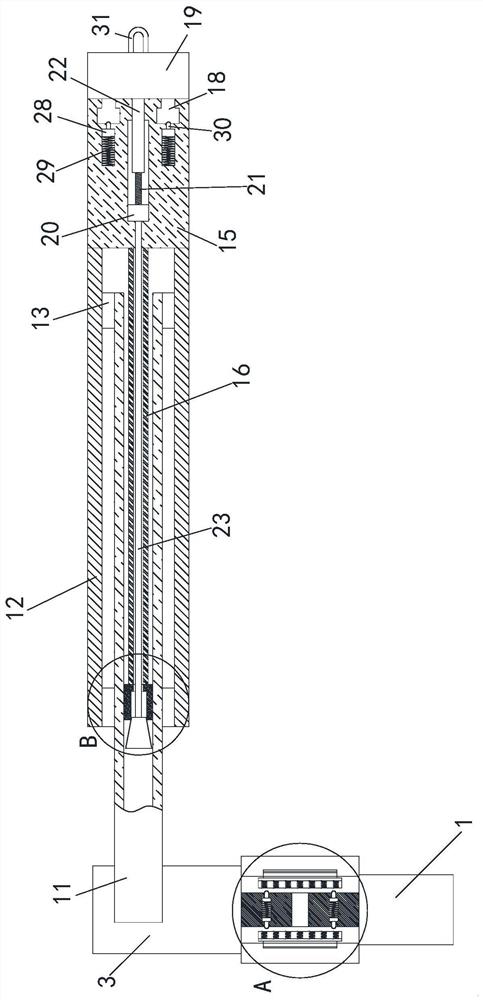

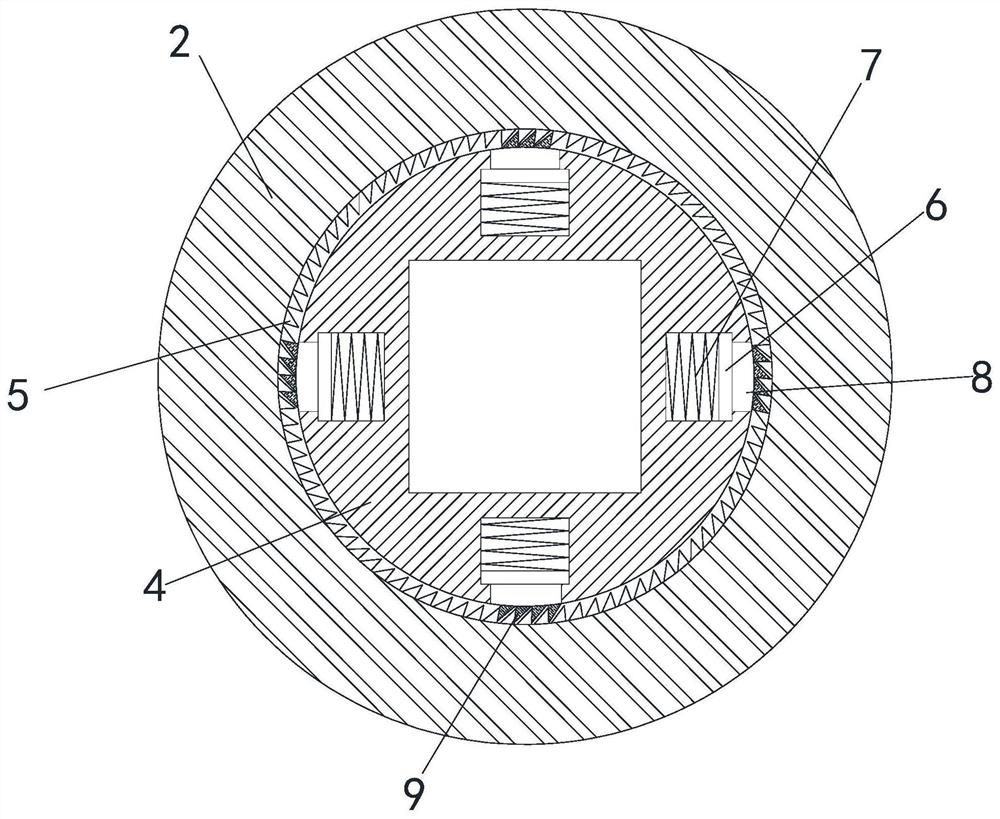

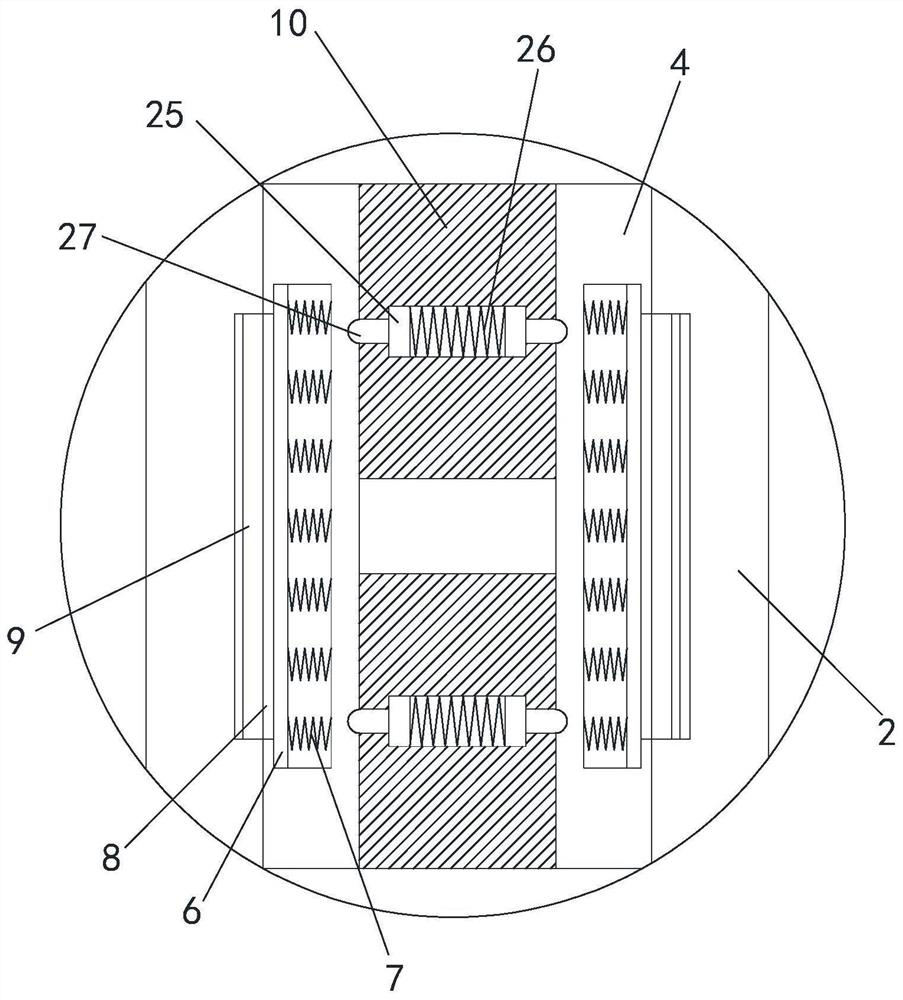

[0025] see Figure 1-4 , a wrench for fastening high-strength bolts, comprising a sleeve 1, a sleeve column 2 and a fixed column 3, the top of the sleeve column 2 is provided with a longitudinally penetrating circular groove, and the inner rotation of the circular groove is connected with a connecting column 4, The top of the connecting column 4 is provided with a vertically penetrating square through groove, and the outer wall of the circular groove is provided with a ring groove, and the inside of the ring groove is evenly and fixedly connected with a plurality of first locking teeth 5, and the inside of the connecting column 4 is circular. The array is provided with four first slide slots, the first slide slot is provided with a first slide plate 6, and the end of the first slide plate 6 close to the square channel is fixedly connected with a plurality of first compression springs 7, and the first slide plate 6 is far away from the One end of the square through groove is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com