Gas well natural gas dehydration treatment device

A processing device and natural gas technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of reducing the service life of equipment, clogging valves, power consumption, etc., achieve a high degree of automation and reduce the degree of spin , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

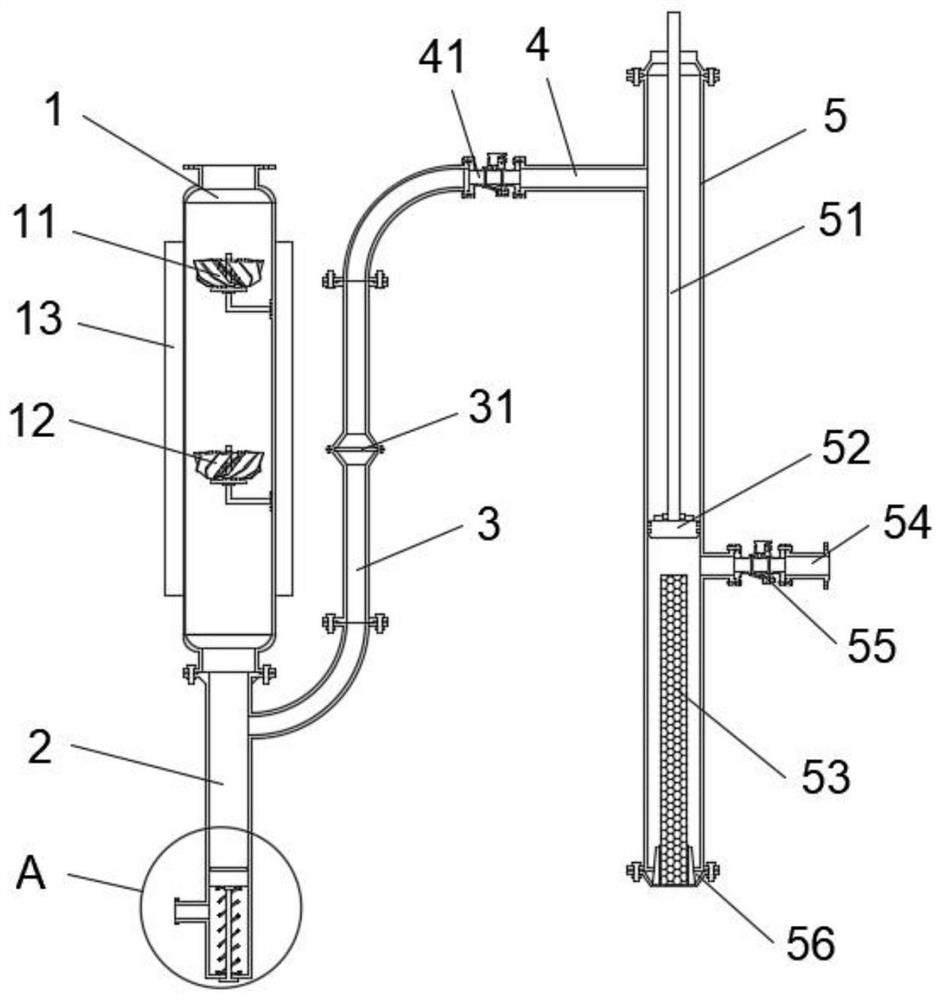

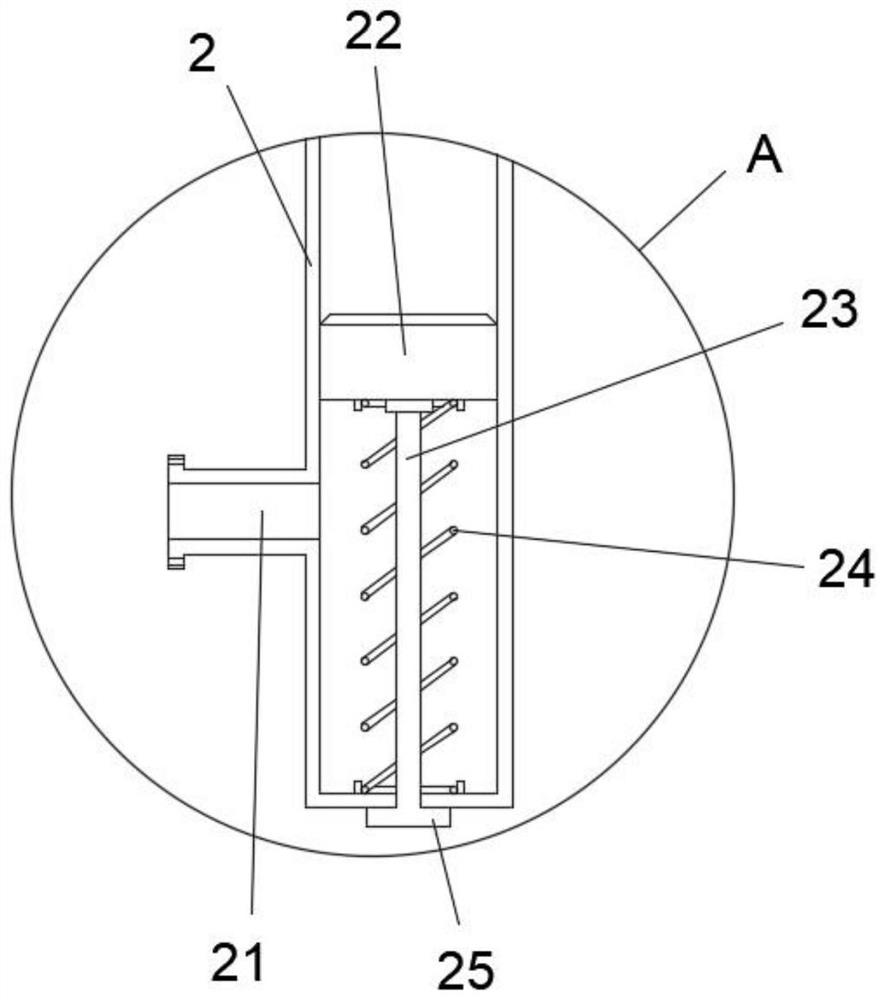

[0025] Combine Figure 1-2 , Including condenser 1, the drain 2, 3 return pipe, the connection pipe 4 and the compression pipe 5, the condenser 1 from the top to bottom with a spin-up means 11 provided helicase apparatus 12, the spin-up means 11 helicase means 12 employed in the particular embodiment the inclined direction of the blade opposite the blade, a condenser side cooling apparatus provided with a guide sleeve 13, the drain pipe 2 to the top condenser and a bottom end communicating, side 2 is provided with drain 2 and the drain discharge port 21 further includes a drain means, both ends of the return pipe 3 as a top arcuate quarter circle with a condenser tube 1 communicates, within the return pipe 3 is provided with a gas separation membrane 31, the said connecting pipe 4 and the two ends of the return pipe 3 to the top, the top of the pipe 5 is connected to the compression, the connection pipe 41 is provided with a first electromagnetic valve 4, the tube 5 includes a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com