Self-locking screw and self-locking assembly using same

A technology of self-locking screw and thread part, which is applied in the field of radio frequency communication, can solve the problems of broken thread section of self-locking screw, small rebound force, poor locking effect, etc., and achieve the effect of improving locking force and strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

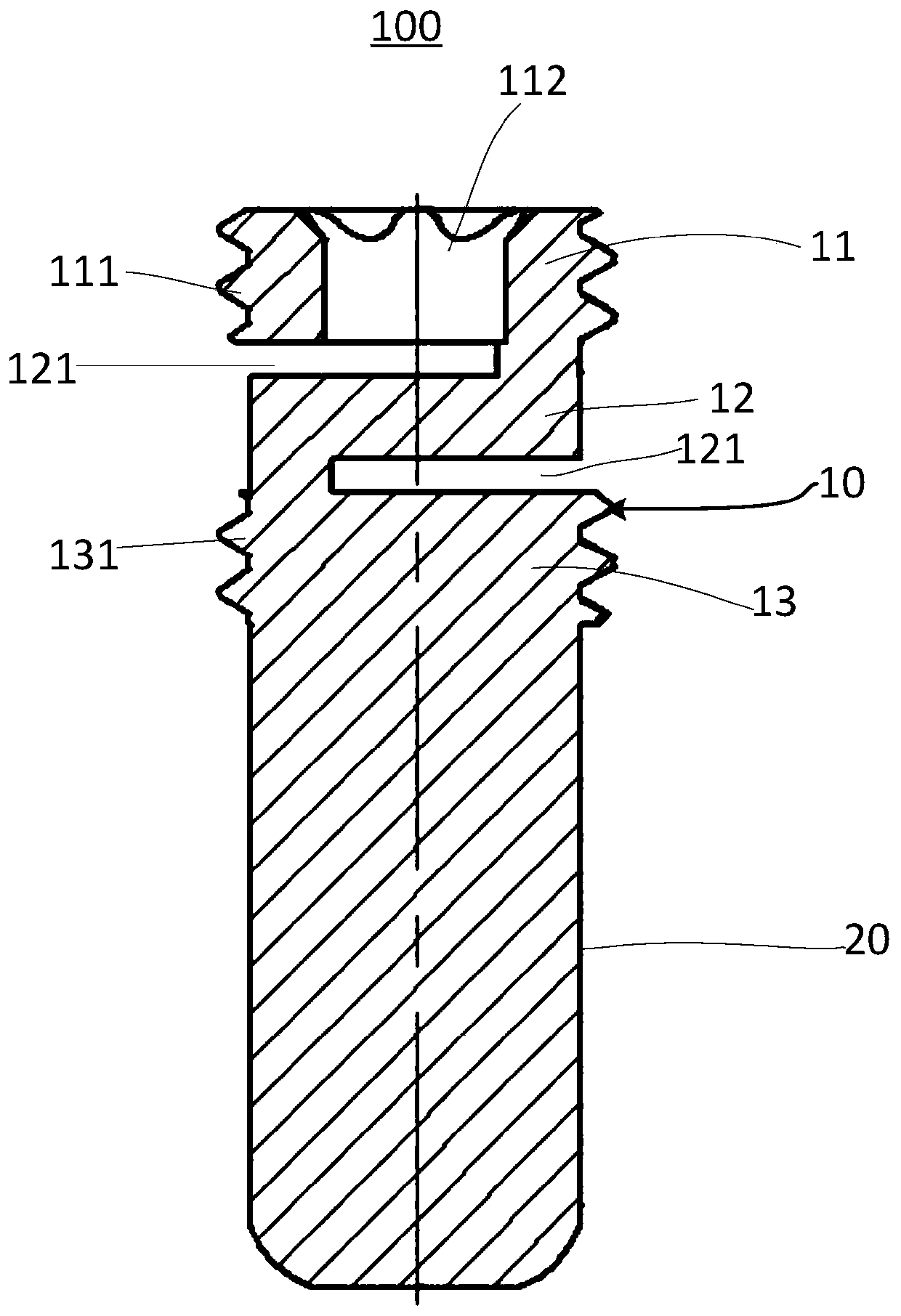

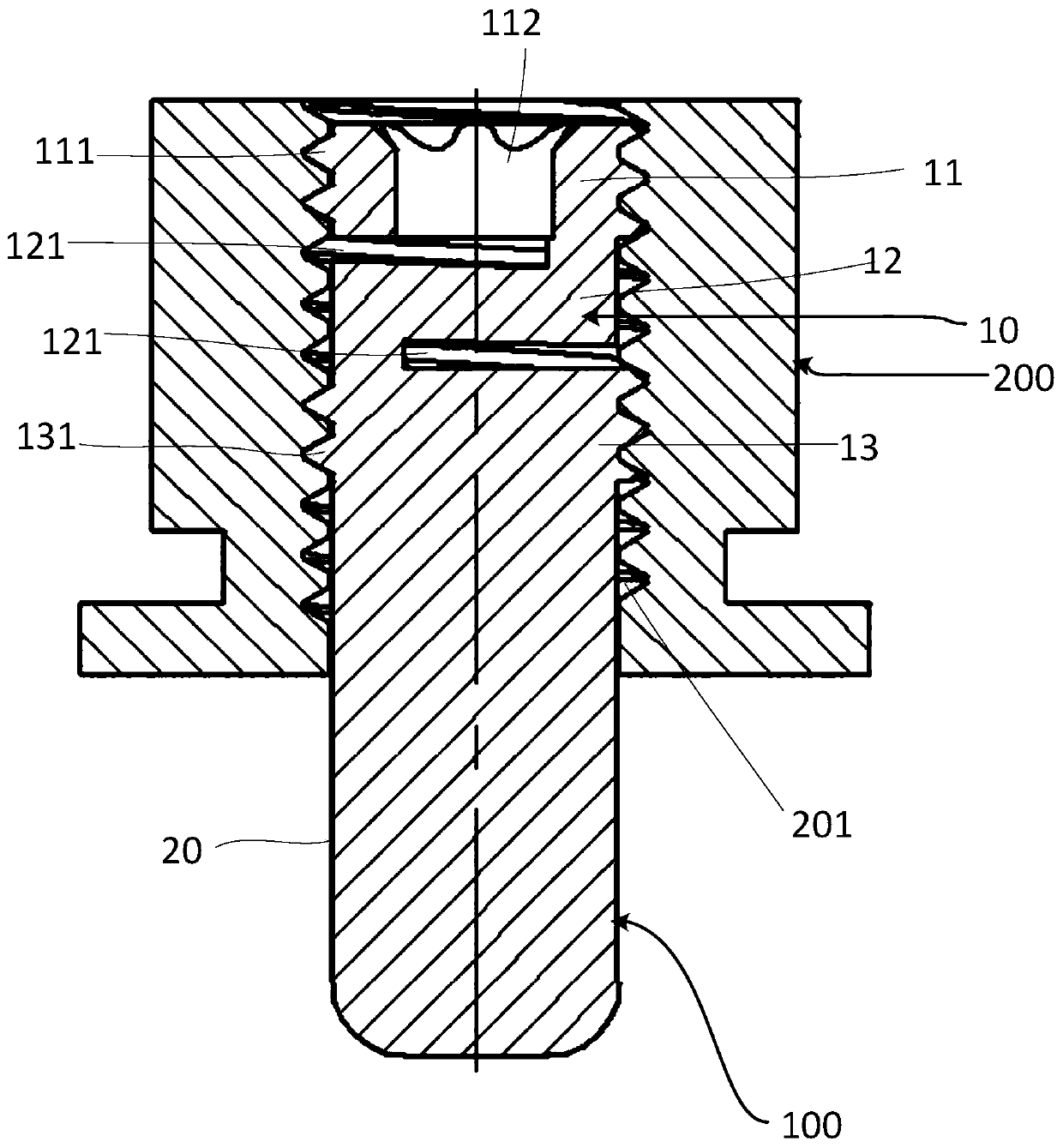

[0023] refer to figure 1 and figure 2 , a self-locking screw 100 provided by the present invention includes a threaded section 10 and a tuning section 20 formed at one end of the threaded section 10 .

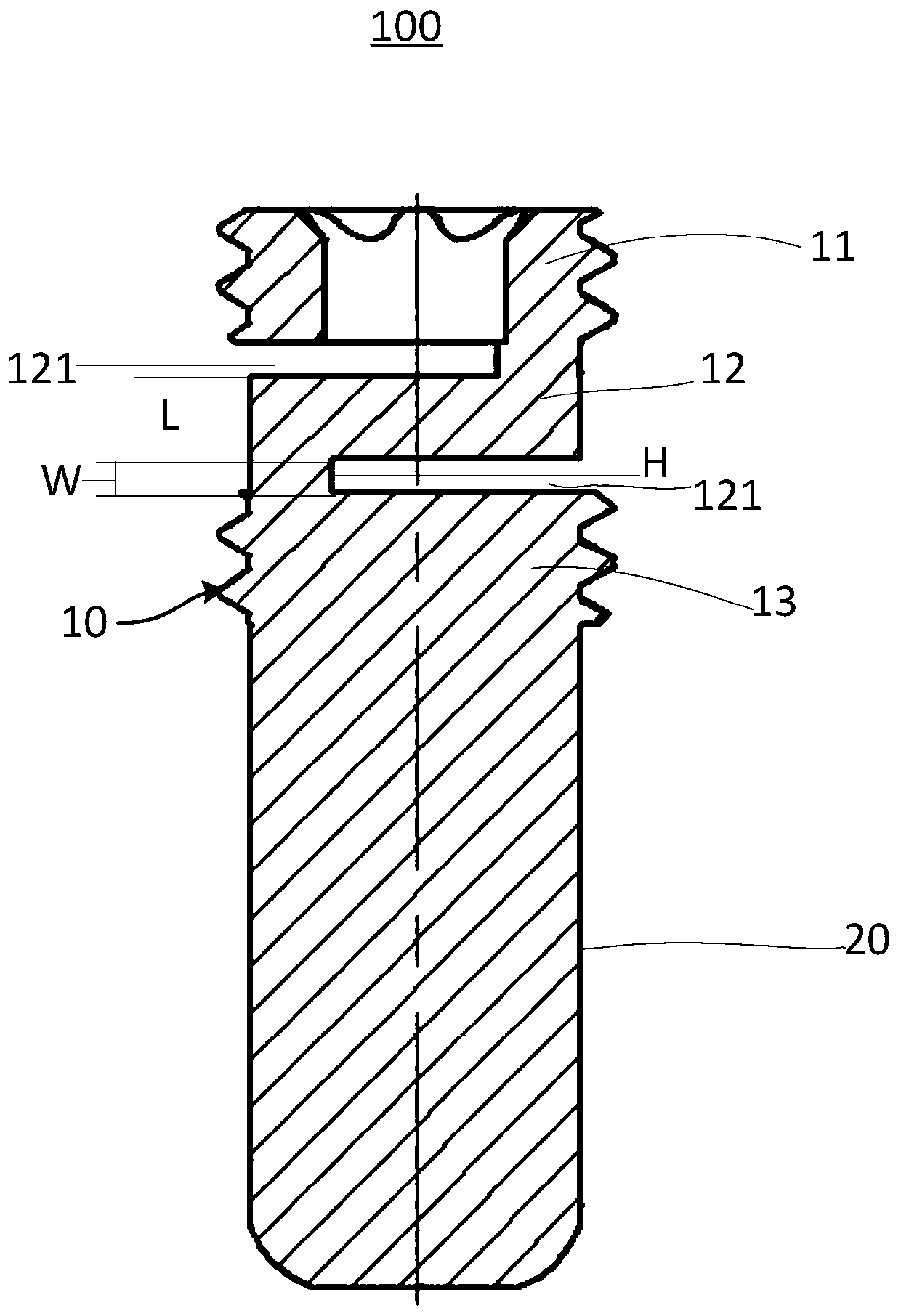

[0024] The threaded section 10 includes a first threaded portion 11, a second threaded portion 13, and an elastic portion 12 connected between the first threaded portion 11 and the second threaded portion 13, and the tuning section 20 is formed on the second threaded portion 13 away from the elastic portion. 12 at one end.

[0025] The elastic portion 12 is provided with two offset and symmetrical radial slots 121 . The two radial slots 121 are respectively adjacent to the first threaded portion 11 and the second threaded portion 13 . Preferably, the two radial slots 121 respectively extend to the connection between the elastic portion 12 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com