A steel structure drum-shaped welding ball positioning adjustment method

A positioning adjustment and welding ball technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult positioning, affecting construction, and low installation efficiency, so as to achieve easy operation for workers and guaranteed assembly accuracy , The effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

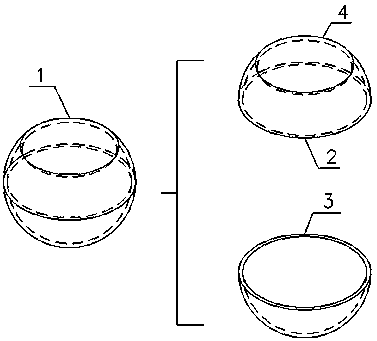

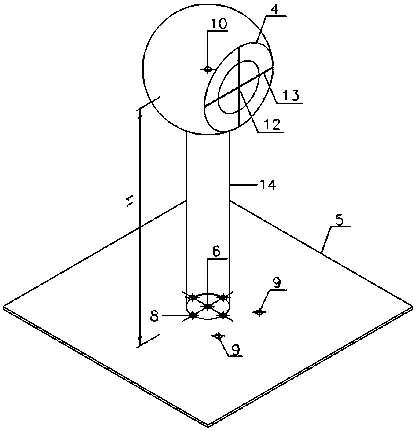

[0038] according to figure 1 As shown, the drum-shaped welding ball 1 is welded together by a drum-shaped shell 2 and a hemispherical shell 3 . combine Figure 2~5 As shown, the preferred embodiments of the present invention are further described in detail.

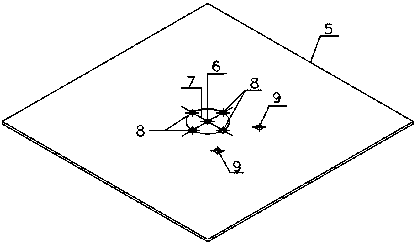

[0039] The first step is to level the site and lay steel plates 5 for assembling;

[0040] The second step is to adjust the assembly posture of the unit on the CAD model, provide the coordinates of the center of the welding sphere 10 and the relative height difference 11, and provide the coordinates of the measurement control point 15 of the drum surface 4;

[0041] In the third step, according to the coordinates of the center of sphere coordinates 10 and the coordinates of the measurement control point 15 of the drum-shaped surface 4, utilize the measuring instrument to release the coordinates of the center of the sphere projection point 6 and the coordinates of the measurement control projection point of the drum-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com