A fuel tank strap and rubber sleeve assembly jig and assembly method thereof

A technology of rubber sleeves and straps, applied in manufacturing tools, hand-held tools, etc., can solve the problems of difficult assembly, low assembly efficiency, and no identical or similar patent documents are found, so as to reduce assembly difficulty and improve assembly efficiency. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

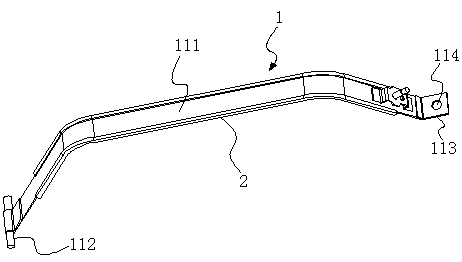

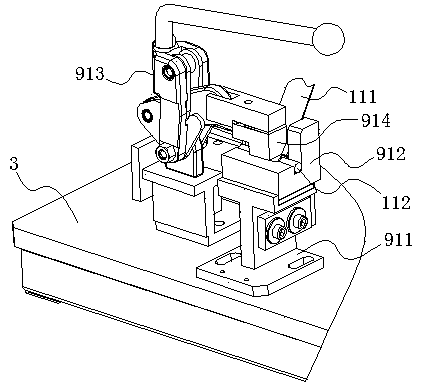

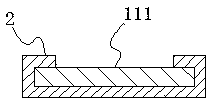

[0050] Example: such as Figure 3 to Figure 6 As shown, an assembly jig for a fuel tank strap and a rubber sleeve includes a working platform 3, and also includes a lifting handle 1 4 and a lifting handle 2 5 arranged on the working platform 3, and the lifting handle 1 4 and the lifting handle 2 5 are both Slidingly connected on the working platform 3 through the guide rail 6, the lifting handle 1 4 and the lifting handle 2 5 are connected together through the cylinder mechanism 7, under the action of the cylinder mechanism 7, the lifting handle 1 4 and the lifting handle 2 5 can be relatively close Move or move relatively far away, on the working platform 3 between the lifting handle one 4 and the lifting handle two 5, a rubber sleeve support block 8 is also provided, and on the working platform 3 located at the two ends of the rubber sleeve support block 8, respectively set There are strap fixing device one 9 and strap fixing device two 10;

[0051] By setting the rubber sl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap