Automobile Front Axle with Side Impact Energy-absorbing Structure

An energy-absorbing structure, the technology of the front axle of a car, applied to axles, wheels, vehicle parts, etc., can solve problems such as poor safety, achieve good side impact resistance, and increase the effect of elements involved in energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

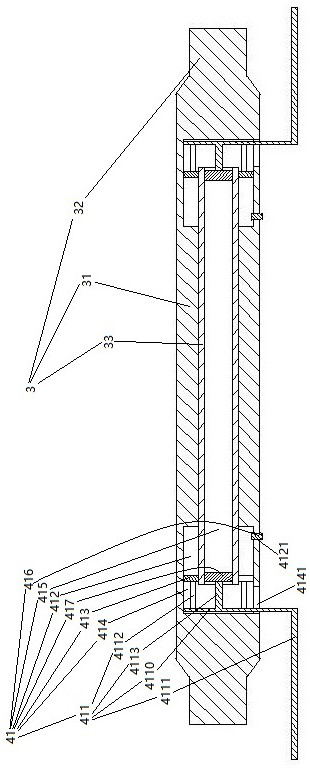

[0019] Embodiment one, see figure 1 , an automobile front axle provided with a side impact energy-absorbing structure, comprising a front axle 3 .

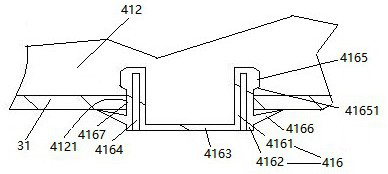

[0020] The front axle 3 includes a cross bar 31 and two suspension arms 32 located at both ends of the cross bar. A side impact energy-absorbing structure 41 is respectively provided at the left and right ends of the cross bar 31 .

[0021] The side impact energy-absorbing structure 41 includes a drive frame 411 , a cylinder 412 , a compression piston 413 , a first frictional energy-dissipating cylinder 414 and a second frictional energy-dissipating cylinder 415 .

[0022] A pipe body 33 is slidingly sealed in the cross bar 31 . The pipe body 33 extends in the left-right direction. The inner space of the pipe body 33 constitutes a total of two second frictional energy dissipation cylinders 415 of the two side impact energy absorbing structures 41 . A third friction layer is provided on the inner peripheral surface of the secon...

Embodiment 2

[0029] Embodiment two, the difference with embodiment one is:

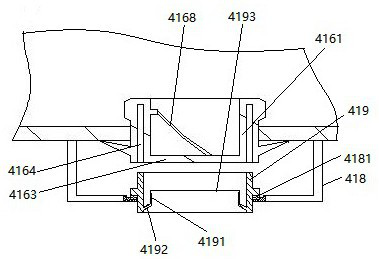

[0030] see image 3 , the inner peripheral surface of the inner tube 4161 is provided with fan blades 4168 that guide the sealing head 416 to rotate when the fluid flows through the inner tube. The crossbar 31 is also provided with a support frame 518 . The supporting frame 418 is rotatably connected with a connecting sleeve 419 through a plane bearing 4181 . The connecting sleeve 419 is connected with an annular blade 4191 . A limiting portion 4192 is formed between the annular blade 4191 and the connecting sleeve 419 . The blade 4191 is provided with an annular cutting edge 4193 . The annular cutting edge 4193 is aligned with the bottom wall 4163 . The outer diameter of the blade 4191 is equal to the inner diameter of the inner circular tube 4161.

[0031] During use, if the sealing head 416 is ejected, before the annular cutting edge 4193 contacts the bottom wall 4163, the connecting sleeve 419 is first i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com