A Post-processing Technology for Embroidery Embroidery

An embroidery and embroidery technology, applied in the field of post-processing technology of embroidery embroidery, can solve the problems of color shedding, damage and erosion, embroidery thread rot, etc., reduce the requirements of the preservation environment, ensure the barrier performance, and improve the effect of blocking air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

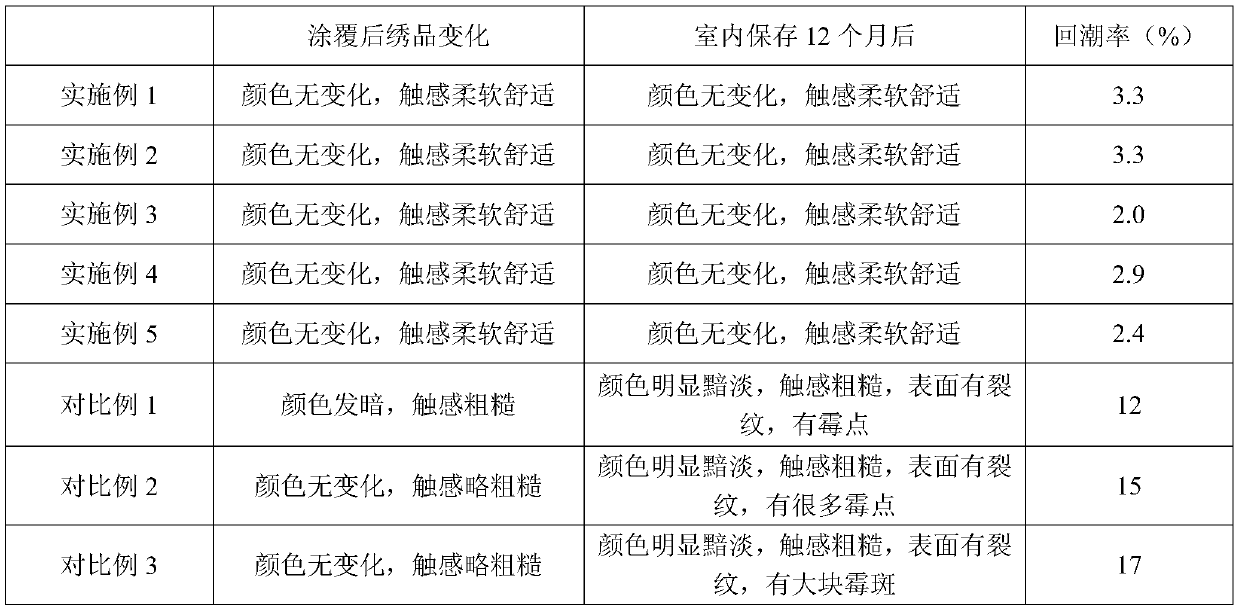

Examples

Embodiment 1

[0026] A post-processing technique for embroidery embroidery, comprising the following steps:

[0027] (1) Put the embroidery under the ultraviolet light for 20 minutes to kill most bacteria, mold and other microorganisms;

[0028] (2) After taking out the embroidery, evenly coat the protective agent on its front and back to form a protective film; the protective agent is made of the following components by weight: 30 parts of acrylate copolymer emulsion, carnauba wax emulsion 20 parts, 10 parts of glycidyl methacrylate, 12 parts of polypropylene glycol diglycidyl ether, 5 parts of polyvinyl alcohol, 3 parts of propylene glycol butyl ether, 1 part of pearl fiber, 1000 parts of water;

[0029] (3) Transfer the embroidery to the smoker, and light the pine branches for smoke treatment, which will help the embroidery to dry and kill residual bacteria and mold.

[0030] Wherein, the irradiation intensity of the ultraviolet lamp in step (1) is 220 μ W / cm 2 .

[0031] The preparat...

Embodiment 2

[0038] A post-processing technique for embroidery embroidery, comprising the following steps:

[0039] (1) Put the embroidery under the ultraviolet light for 30 minutes to kill most bacteria, mold and other microorganisms;

[0040] (2) After taking out the embroidery, evenly coat the protective agent on its front and back to form a protective film; the protective agent is made of the following components by weight: 40 parts of acrylate copolymer emulsion, carnauba wax emulsion 30 parts, 18 parts of glycidyl methacrylate, 15 parts of polypropylene glycol diglycidyl ether, 8 parts of polyvinyl alcohol, 4 parts of propylene glycol butyl ether, 2 parts of pearl fiber, 1000 parts of water;

[0041] (3) Transfer the embroidery to the smoker, and light the pine branches for smoke treatment, which will help the embroidery to dry and kill residual bacteria and mold.

[0042] Wherein, the irradiation intensity of the ultraviolet lamp in step (1) is 220 μ W / cm 2 .

[0043] The prepara...

Embodiment 3

[0050] A post-processing technique for embroidery embroidery, comprising the following steps:

[0051] (1) Put the embroidery under the ultraviolet light for 20 minutes to kill most bacteria, mold and other microorganisms;

[0052] (2) After taking out the embroidery, evenly coat the protective agent on its front and back to form a protective film; the protective agent is made of the following components by weight: 40 parts of acrylate copolymer emulsion, carnauba wax emulsion 20 parts, 18 parts of glycidyl methacrylate, 12 parts of polypropylene glycol diglycidyl ether, 8 parts of polyvinyl alcohol, 3 parts of propylene glycol butyl ether, 2 parts of pearl fiber, 1000 parts of water;

[0053] (3) Transfer the embroidery to the smoker, and light the pine branches for smoke treatment, which will help the embroidery to dry and kill residual bacteria and mold.

[0054] Wherein, the irradiation intensity of the ultraviolet lamp in step (1) is 220 μ W / cm 2 .

[0055]The preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com