A supporting device between girders of a maglev turnout

A technology of support device and turnout beam, which is applied in the directions of roads, tracks, moving rail parts, etc., can solve the problems of vibration, affecting the service life of the turnout, and the vertical displacement of the turnout beam cannot be well limited. , to achieve the effect of avoiding the service life and reducing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

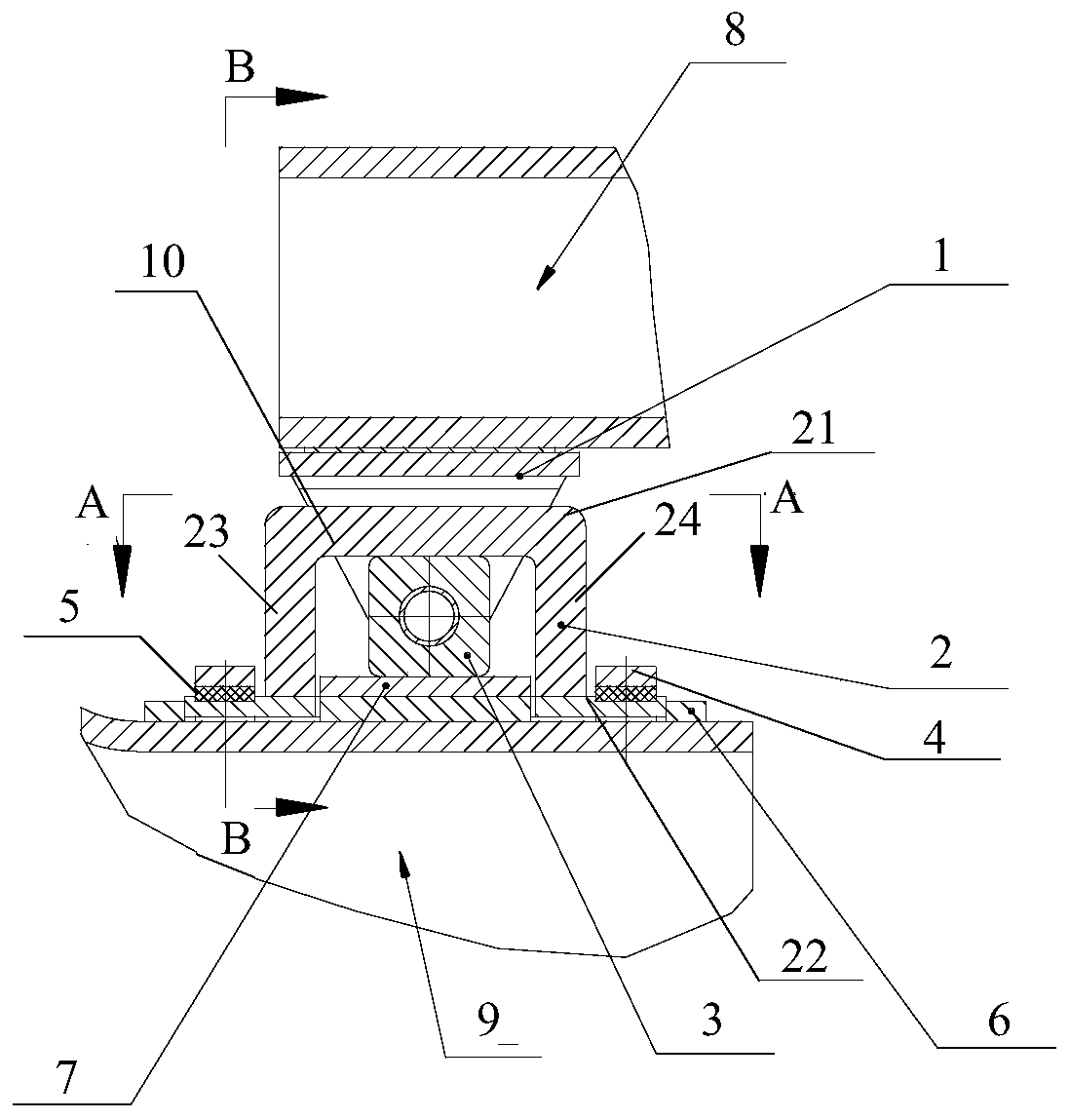

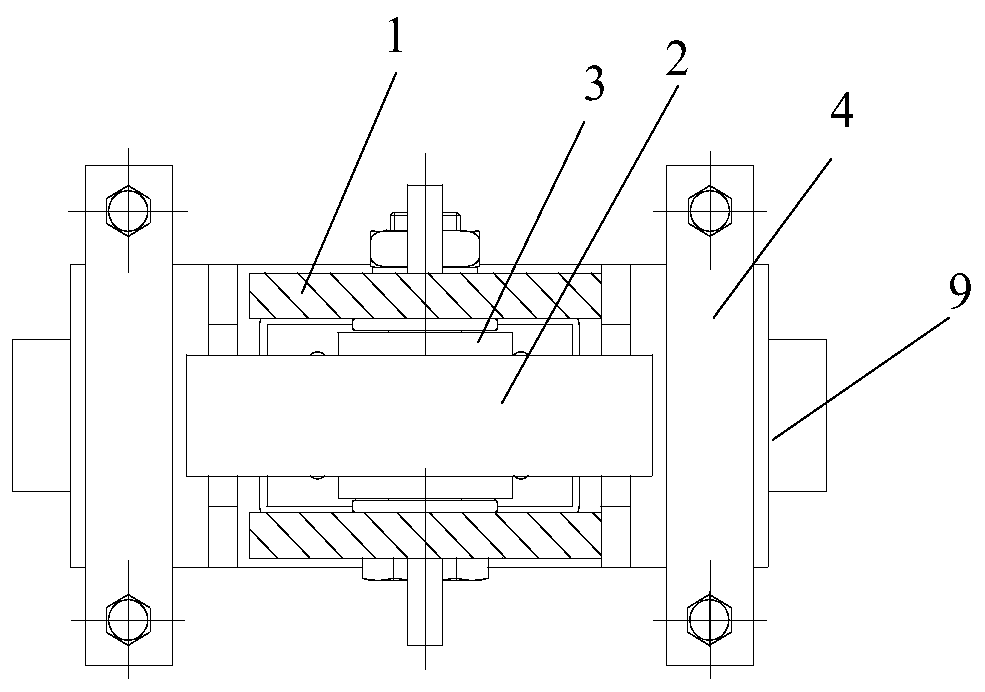

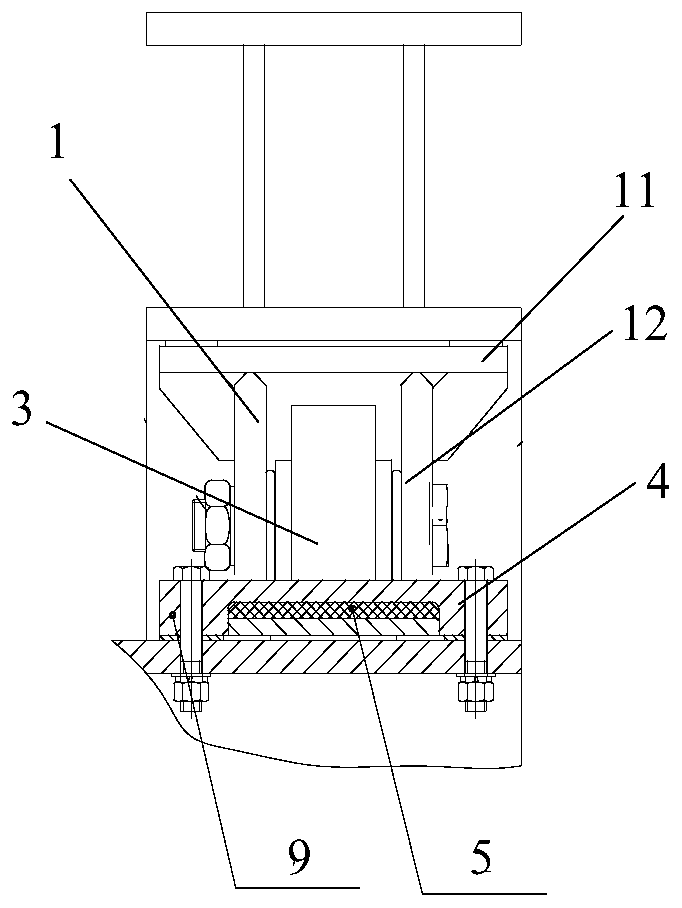

[0024] figure 1 Schematically shows the front view cross-sectional structure of the support device 10 of the embodiment of the present invention. figure 2 A top view cross-sectional structure of the support device 10 according to the embodiment of the present invention is schematically shown. image 3 Schematically shows the cross-sectional structure of the support device 10 in the embodiment of the present invention as viewed from the left. Such as Figure 1 to Figure 3 As shown, the support device 10 according to the embodiment of the present invention includes an upper support 1 connected to the upper turnout beam 8 and a lower support 2 connected to the lower turnout beam 9, and is connected to the upper support 1 in a detachable manner. slider 3. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com