Reflection efficiency detection device for reflection magnet for radiation

A technology of reflection efficiency and detection device, which is applied in the direction of measuring device, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc., can solve problems such as complex structure of equipment, armor deformation, huge equipment, etc., to ensure Effect of Irradiance Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

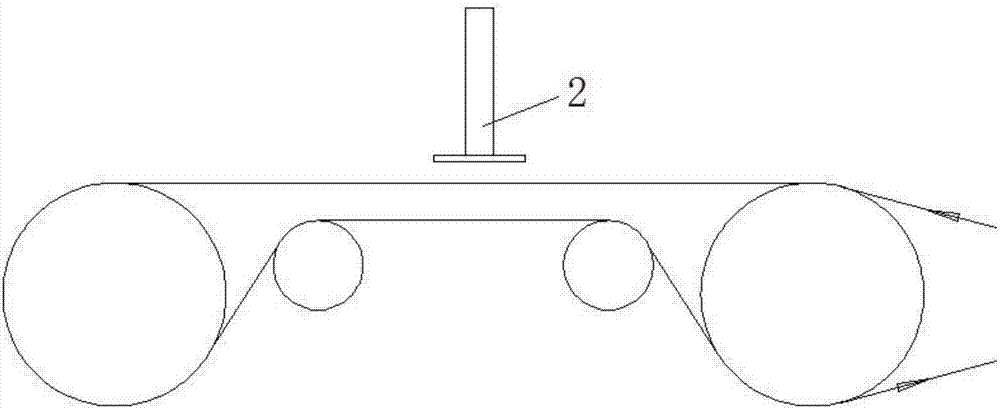

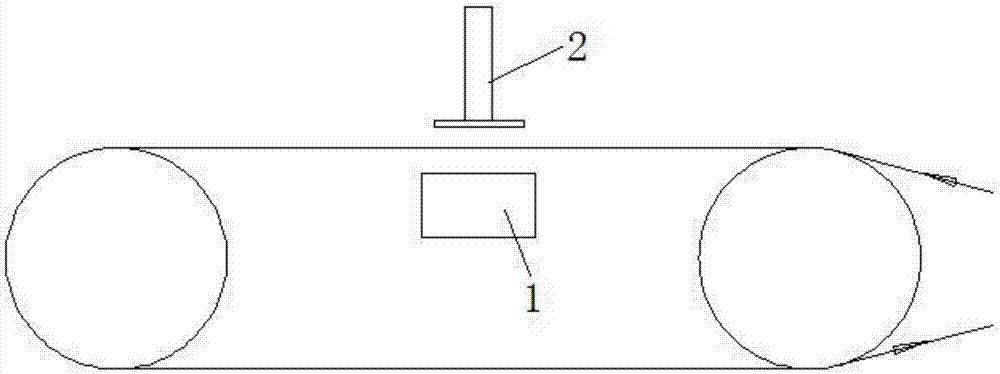

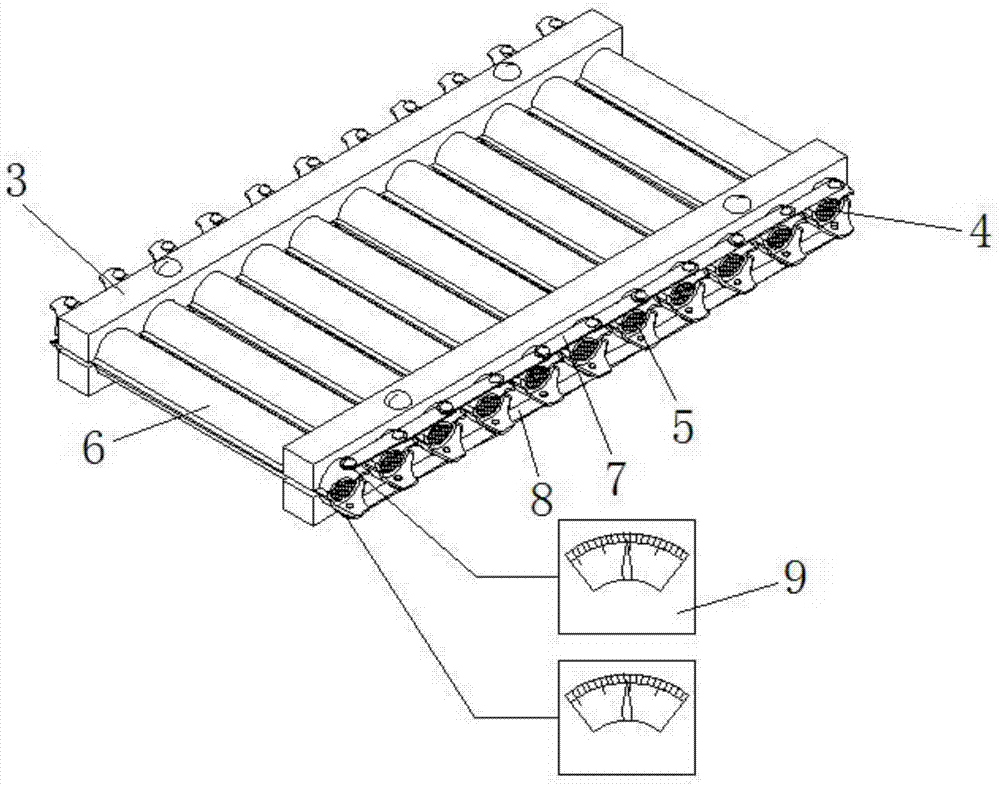

[0026] After irradiation with reflective magnets, the front and back of the cable are irradiated at the same time. As long as the reflection efficiency of the lower end electron beam is ensured, the uniformity of the front and back irradiation doses can be guaranteed, and the dose caused by the rotation of the cable during transmission is eliminated. Inhomogeneity. After the reflection magnet is installed in place, it is necessary to detect the reflection efficiency and adjust the parameters of the reflection magnet to achieve the highest reflection efficiency, so as to ensure the radiation quality of the cable. Aiming at detecting the reflection efficiency of a reflection magnet, the present invention provides a reflection efficiency detection device of a reflection magnet for irradiation to meet the detection requirements.

[0027] The technical solutions of the present invention will be clearly and completely described below through specific embodiments. Apparently, the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com