Wire branching comb of thermal shrinkage slim tube irradiation device

A technology for irradiation devices and thin tubes, applied in irradiation devices, nuclear engineering, etc., can solve problems such as deterioration of tube irradiation quality, and achieve the effect of ensuring irradiation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

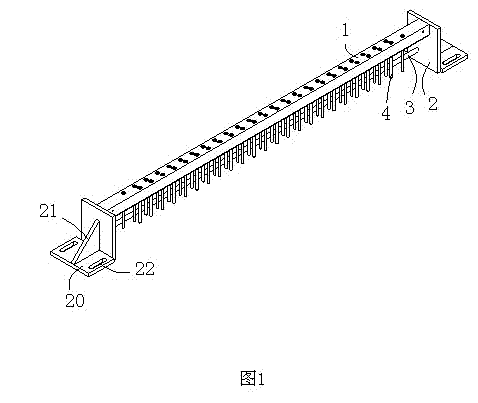

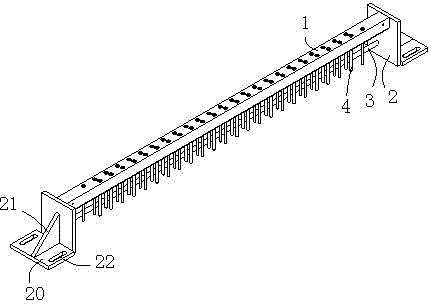

[0010] Such as figure 1 As shown, the heat-shrinkable tubing and electronic wire and tube irradiation device of the present invention has a sparse line, including a main body 1, and fixing seats 2 arranged at both ends of the main body 1, and arranged below the main body 1 to connect two The guide rod 3 of the fixed seat 2; the main body 1 is equipped with a flexible rotating vertical rod 4, the vertical rod 4 has at least two rows, and the vertical rods 4 in different rows have the same spacing. By installing the flexibly rotatable pole 4, it can effectively avoid a large number of scratches on the wire and tube due to friction during the irradiation process, and ensure the irradiation quality of the tube. In this embodiment, the main body 1 is equipped with two rows of flexibly rotating poles 4.

[0011] Wherein, the fixing base 2 includes an L-shaped support portion 20 and a reinforcing rib 21 provided on the support portion 20; the support portion 20 is provided with a screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com