Heddle preferably for processing strip-like warp material and method for producing a heddle

A technology for processing belts and warp yarns, applied in textiles, papermaking, weaving, looms, etc., can solve the problems of complicated and expensive manufacturing of weaving heddles, and achieve the effect of eliminating friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

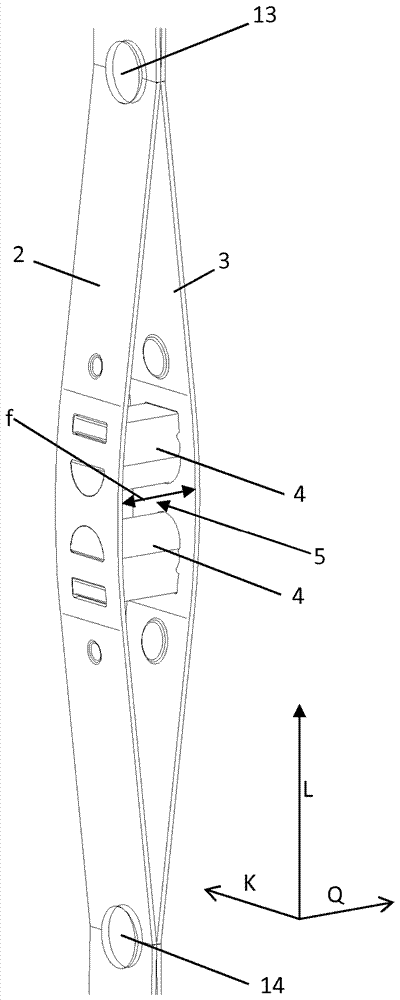

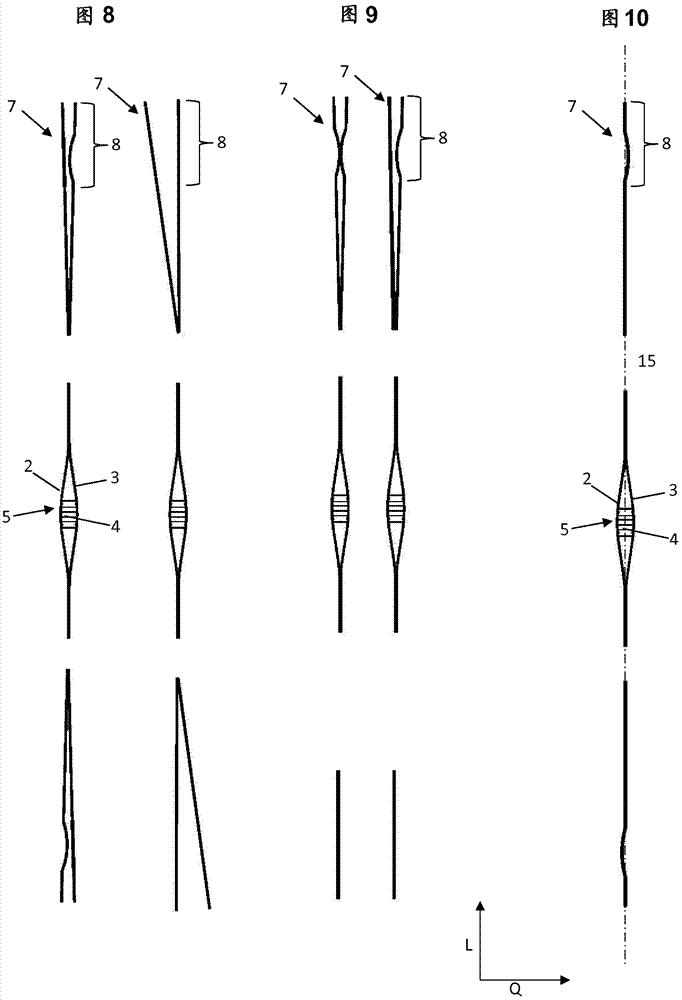

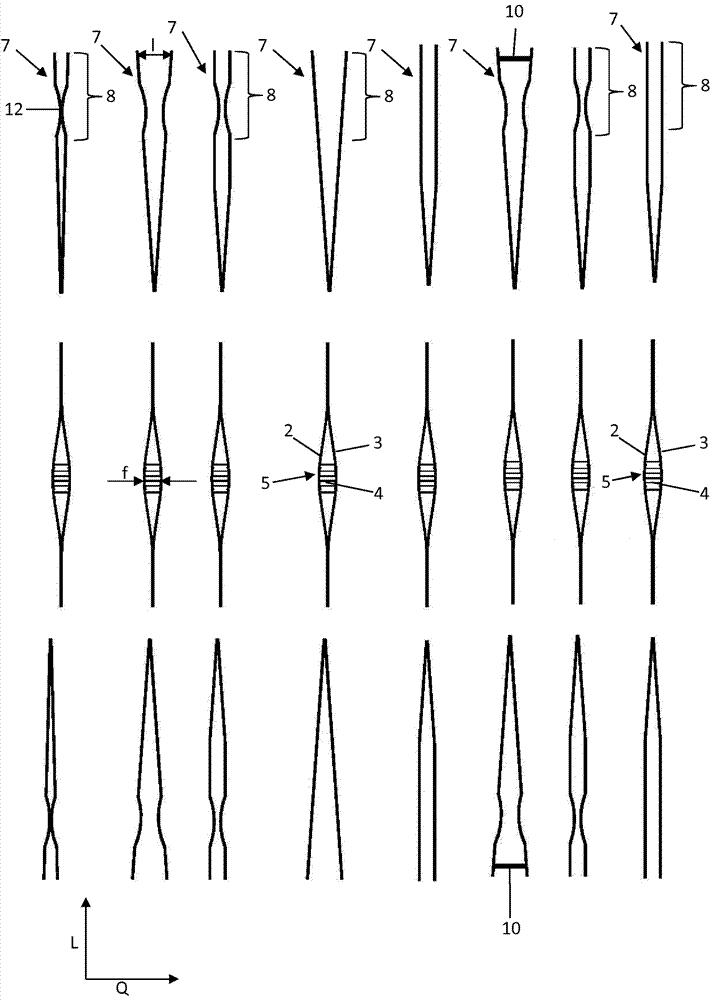

[0052] as by figure 1 As can be seen, the weaving heddle comprises a first strip 2, a second strip 3 and two structural elements 4, by means of which the two strips 2, 3 are aligned in the transverse direction Q in the region of the thread guide eye 5. on separated. Adjoining the eyelet area is a shank area 6 on both sides in the longitudinal direction L. The two strips 2 , 3 rest against each other over a wide distance in the shaft area. At the end of the shank region 6 there is correspondingly an end eye 7 . In the area of the end eyelets 8 (area of the end eyelets 7 ), the two strips are bent over one another in the transverse direction (up to the respective heddle end 9 ) by a length l which is greater than the width of the guide eyelet 5 f (in the transverse direction Q). Additionally, spacer elements (10; see Figure 7 ) is introduced into the end eyelet area 8 . The size of the length l is selected so that when the heddles are mounted on the support rails of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com