Valve for controlling a fluid flow

A technology of fluid communication and fluid inlet, which is applied in the field of gas injection valves and can solve the problems of complex manufacturing and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

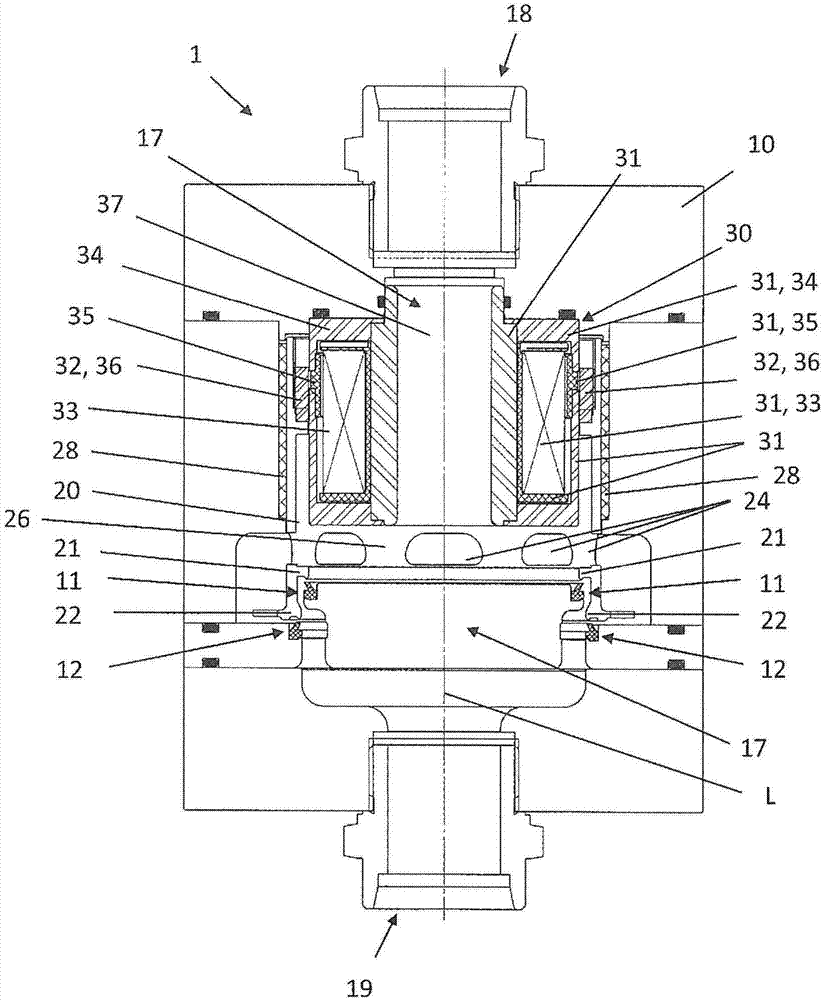

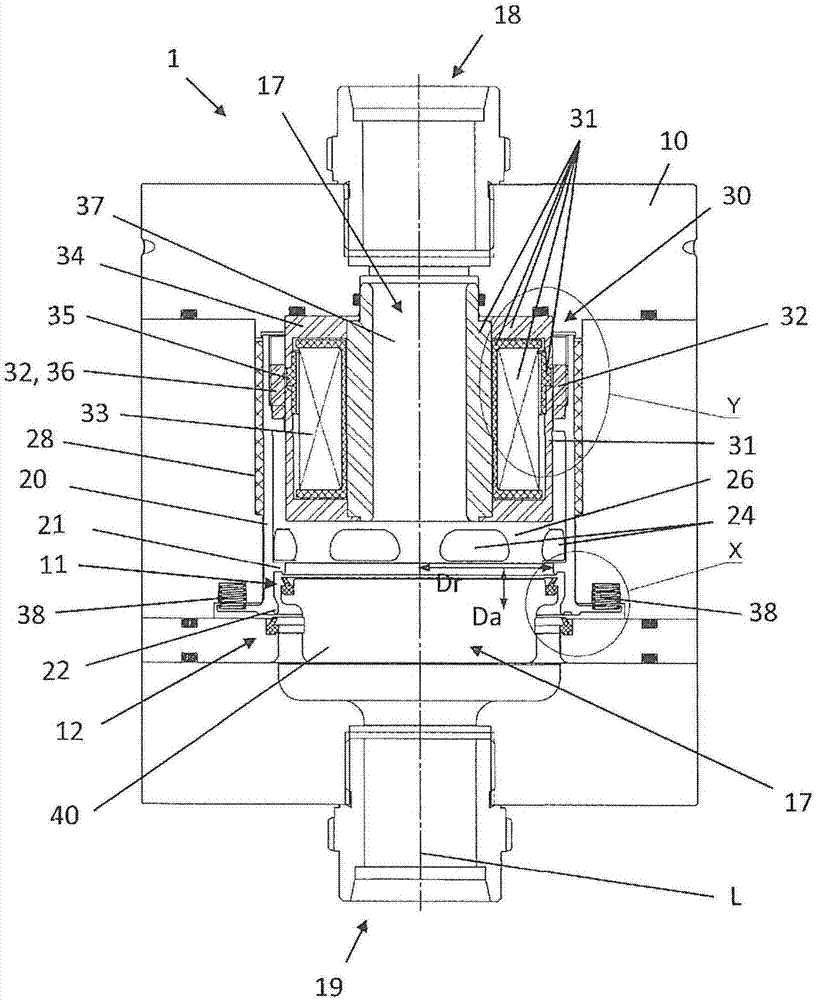

[0045] Figures 1 to 4 One possible embodiment of the valve 1 according to the invention is shown. The valve 1 has a valve housing 10 in which a sleeve section 23 and further The substantially hollow-cylindrical closure element 20 of the sleeve section 26 is arranged displaceably along the sleeve longitudinal axis L on a slide bearing 28 . An actuator 30 is used to move the closure element 20 between the open position and the closed position of the valve 1, which actuator moves the closure element 20 into the closed position against the force of a plurality of return springs 38 distributed around the circumference. middle. Figures 1 to 4 Valve 1 is shown in an open position.

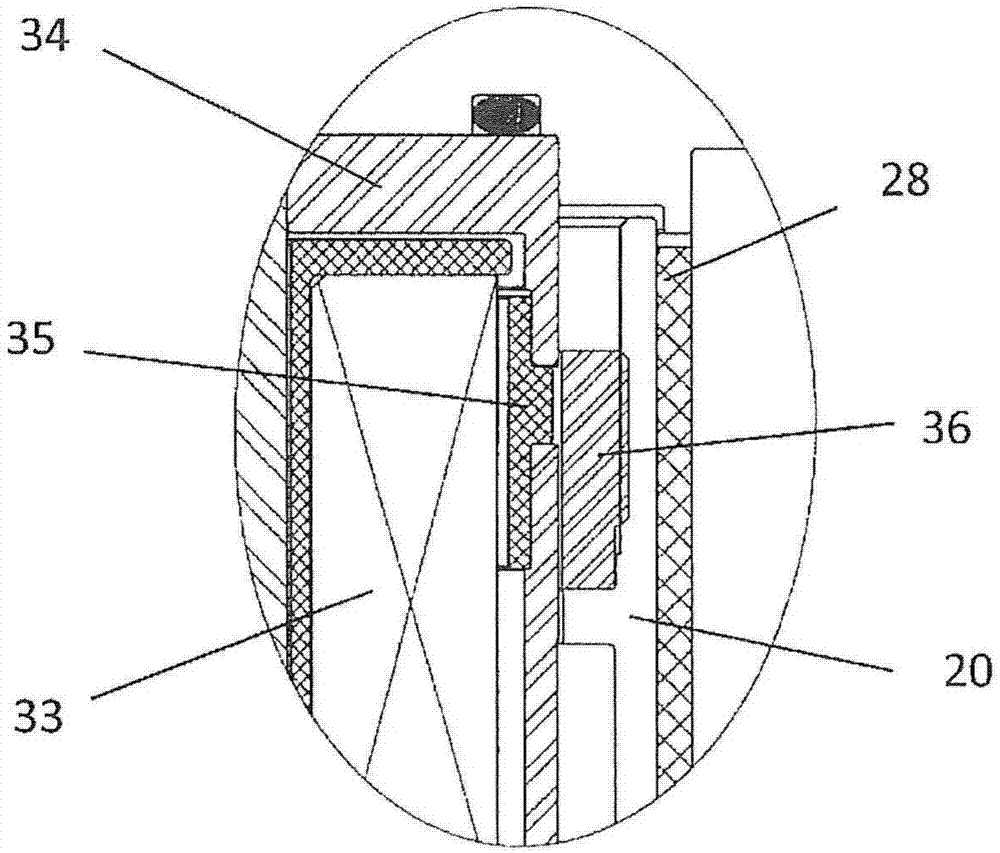

[0046] In the present exemplary embodiment, the actuator 30 is designed as an electromagnetic reluctance actuator having a magnetic field coil 33 , a magnet conductor 34 with an air gap 35 and a magnet armature 36 . In this case, the field coil 33 and the magnet conductor 34 with the air gap 35 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com