Vertical formwork production method for concrete ribbed flat plate

A production method and concrete technology, applied in the production field of precast concrete slabs and reinforced concrete slabs, can solve the problems of non-conformity, waste of land resources, amazing floor space, etc., to improve space utilization, save production costs, and shorten production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the invention.

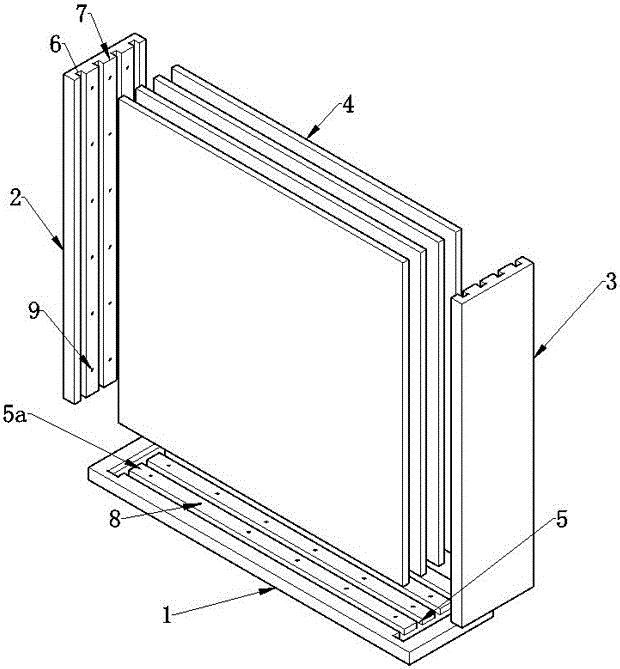

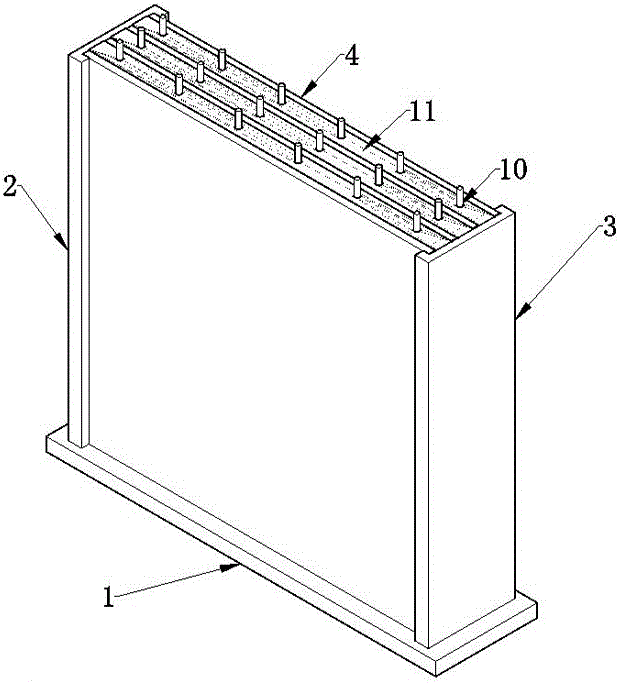

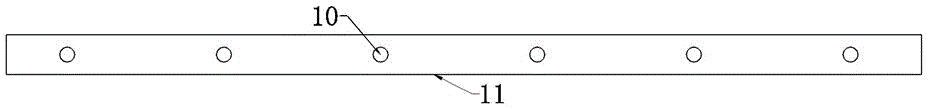

[0047] Such as figure 1 As shown, a ribbed flat casting mold is surrounded by a bottom mold 1, a left mold 2, a right mold 3 and at least two horizontal and vertical molds 4, and the upper surface of the bottom mold 1 is provided with at least two Horizontal through groove 5, form horizontal boss 5a between two horizontal through grooves 5, the inboard of described left side mold 2 and right side mold 3 are all provided with at least two vertical through grooves 6, two vertical through grooves 6 constitute a vertical boss 7, the thickness of the horizontal vertical formwork 4 is not greater than the width of the horizontal through groove 5 on the bottom mold 1 and the vertical through groove 6 inside the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com