Designing and construction structure of beam and plate structure underground garage comprehensive pipe rack

A technology of underground garage and comprehensive pipe gallery, which is applied in infrastructure engineering, underwater structures, artificial islands, etc., to achieve the effect of reducing the excavation depth of the foundation pit and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

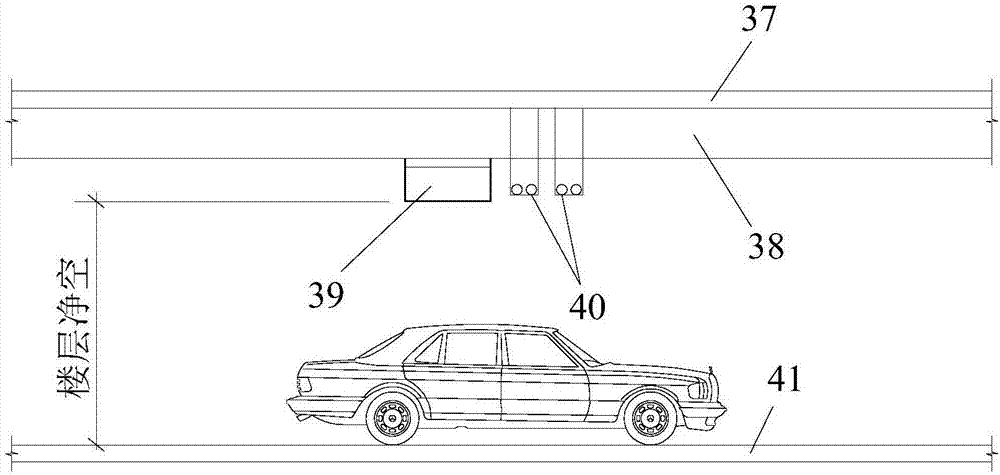

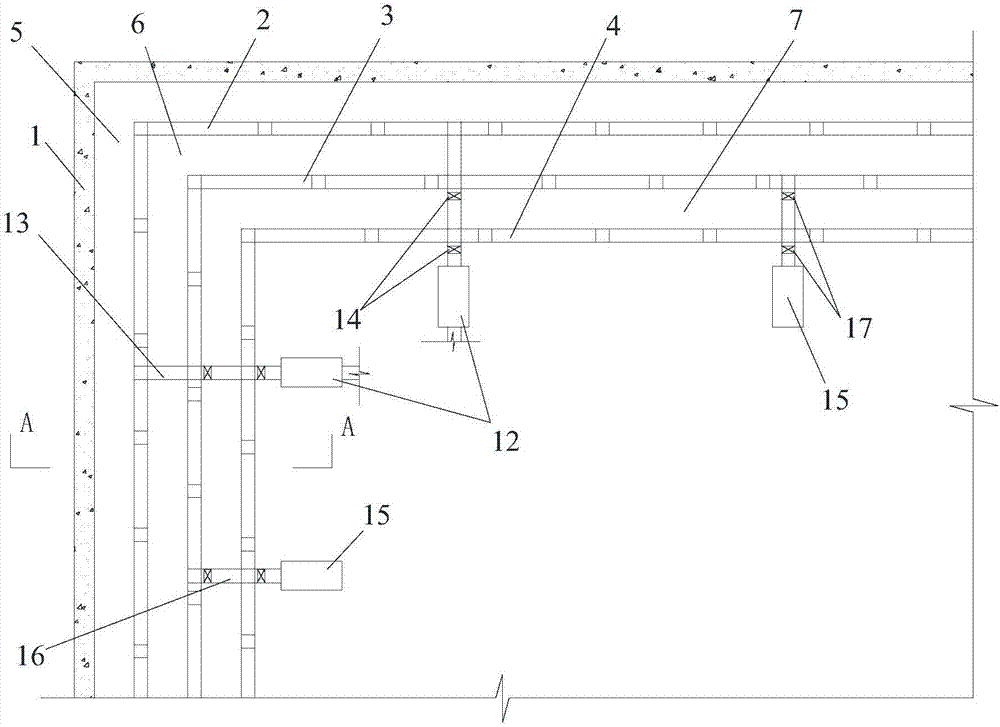

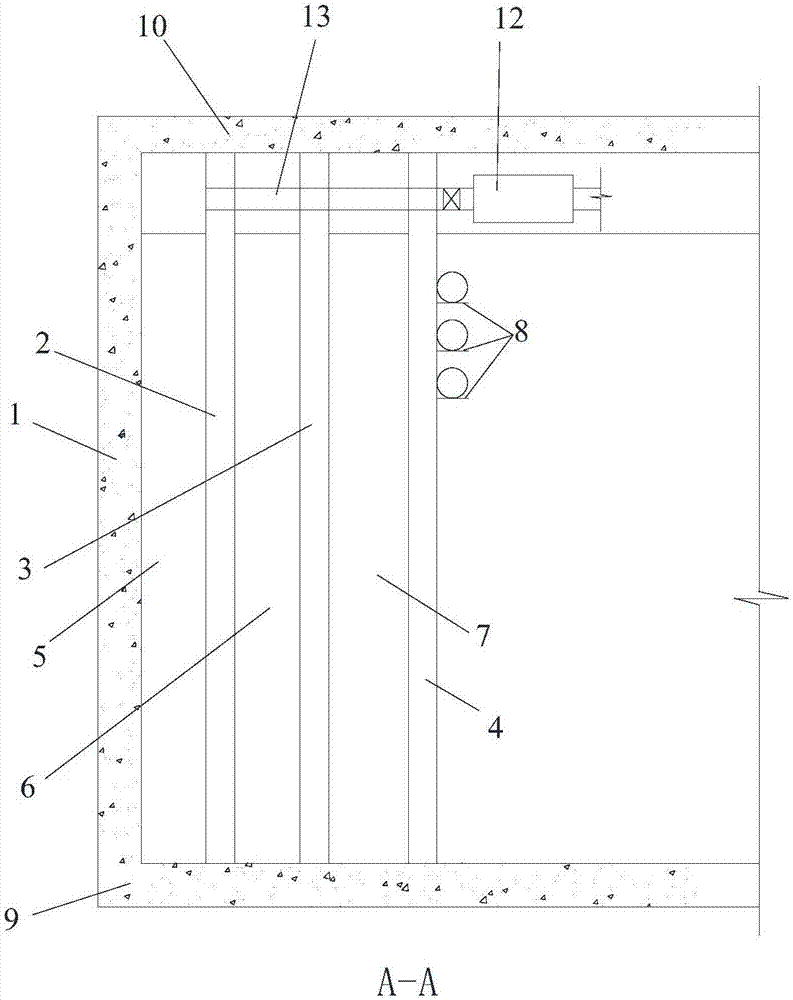

[0064] In this embodiment, the structure of a one-story basement is taken as an example to describe the following.

[0065] Such as Figure 1 to Figure 11 As shown, the design and construction structure of the comprehensive pipe gallery of the beam-slab structure underground garage of the present invention includes a basement layer, and a partition wall 1 2, a partition wall 2 3 and a partition wall 3 4 are sequentially arranged along the outer wall 1 of the basement to the interior of the basement. The basement is also provided with an exhaust duct 5 and an air intake duct 6 for ventilation and air conditioning equipment, a strong and weak electric pipe gallery 7 for installing electrical pipelines, and a bracket 8 for installing main water supply and drainage pipes and heating and ventilation pipes. Wherein, the exhaust duct 5 is a passage formed between the partition wall one 2 and the outer wall 1, and the air inlet duct 6 is a passage formed between the partition wall one...

Embodiment 2

[0078] In this embodiment, the structure of a two-story basement is taken as an example to describe the following.

[0079] Such as Figure 12 to Figure 15 As shown, the design and construction structure of the comprehensive pipe gallery of the beam-slab structure underground garage of the present invention includes two basements. From the first basement to the second basement, the top of the second basement is provided with partitions for respectively supporting the first basement. Structural beam 1 29 and structural beam 2 30 of wall 1 2 and partition wall 2 3 . Partition wall one 2 of the first floor basement is built from the bottom plate 9 top surface of this floor basement to the structural beam one 29 of this floor basement, and partition wall two 3 of the first floor basement is built by laying bricks or stones from the bottom plate 9 top surface of this floor basement To the structural beam two 30 of the basement of this floor. The cross-section of structural beam 1...

Embodiment 3

[0086] In this embodiment, the structure of a three-story basement is taken as an example to describe the following.

[0087] Such as Figure 16 As shown, the design and construction structure of the comprehensive pipe gallery of the beam-slab structure underground garage of the present invention includes three basements. From the first basement to the second basement, each layer is followed by the outer wall 1 of the basement to the inside of the basement. Partition wall one 2 and partition wall two 3 are provided, and each floor basement is also provided with an exhaust duct 5 and an air intake duct 6 for ventilation and air conditioning equipment; wherein, each floor exhaust duct 5 is formed by the partition wall one 2 The channel formed between the outer wall 1 of this layer, the air inlet channel 6 of each layer is the channel formed between the partition wall one 2 of this layer and the partition wall two 3 of this layer, the partition wall one 2 of each layer is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com