Hot melt adhesive cutter body installation structure for towel cloth compounding

An installation structure and hot-melt adhesive technology, applied in lamination devices, layered products, lamination, etc., can solve the problems of not being able to apply glue, inconvenient movement, and affecting the movement of the knife body, so as to achieve convenient movement and rotation, and guarantee The effect of gluing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

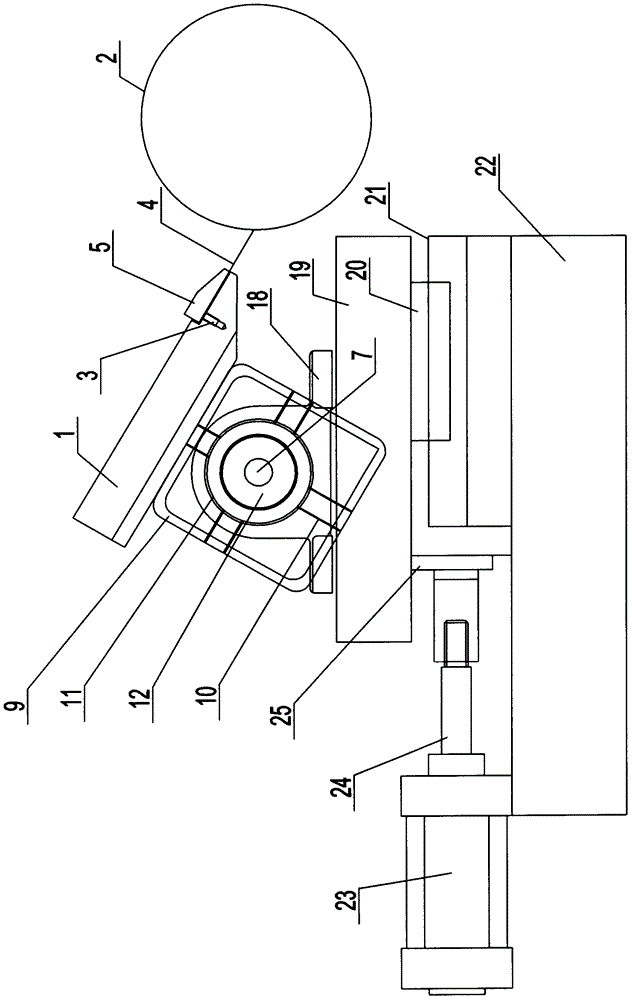

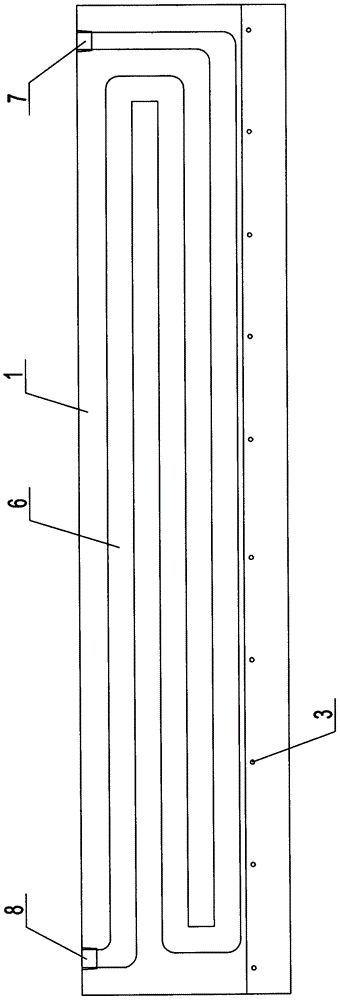

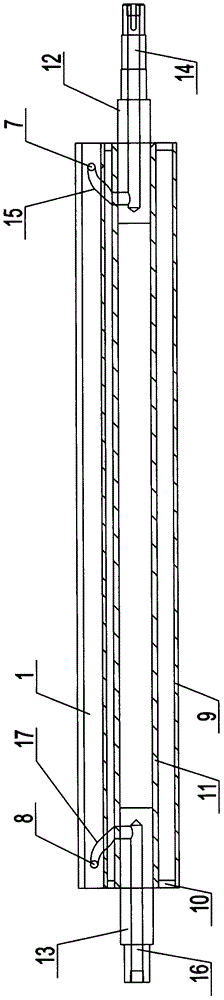

[0011] Such as figure 1 , figure 2 , image 3 As shown, the installation structure of the hot-melt adhesive knife body used for terry cloth compounding includes: a knife body 1 and an upper rubber roller 2, a number of scraper mounting holes 3 are evenly arranged on the knife body 1, and the scraper 4 passes through bolts, scraper blades, etc. The pressure plate 5 and the scraper installation hole 3 are fixed on the cutter body 1, and a labyrinth-type heat-conducting oil heating chamber 6 is arranged inside the cutter body 1, and a labyrinth-type heat-conducting oil heating chamber 6 is arranged on one side of the cutter body 1 The oil inlet 7 connected at one end is provided with the oil outlet 8 connected with the other end of the labyrinth heat transfer oil heating chamber 6 on the other side of the cutter body 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap