Freight carrying platform

A cargo platform and roof technology, which is applied in the field of storage and transportation tools, can solve the problems of unfavorable promotion and application of stackers in the storage market, affecting the working efficiency of cargo platforms and stackers, and inaccurate parking of cargo platforms. , to achieve the effect of shortening the delivery time, shortening the stacking time, and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

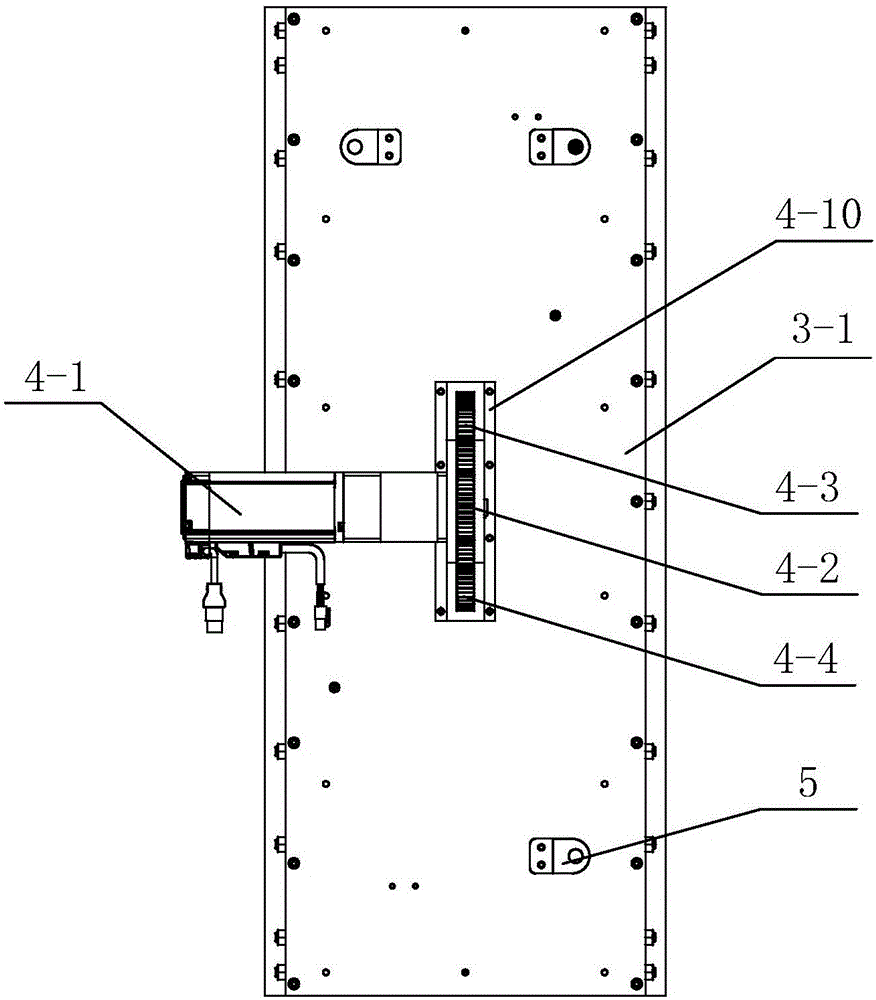

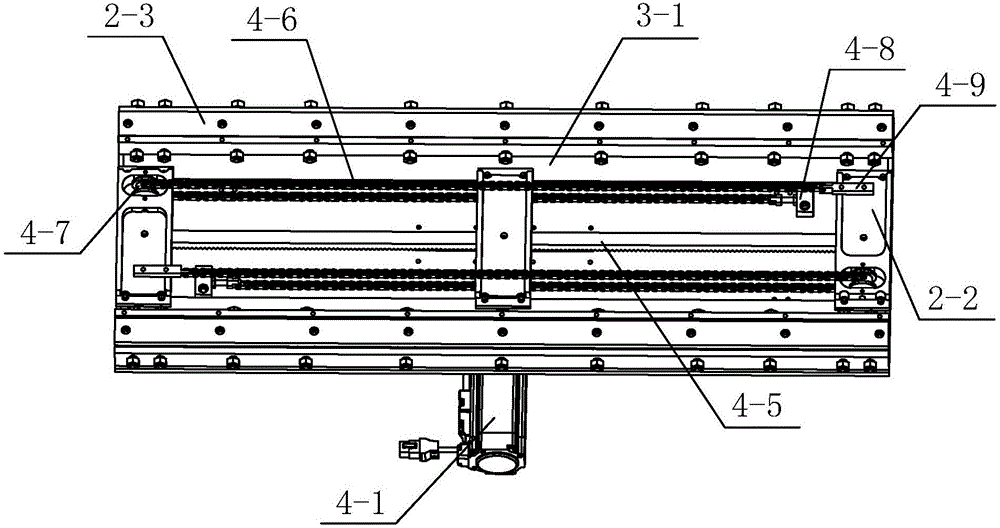

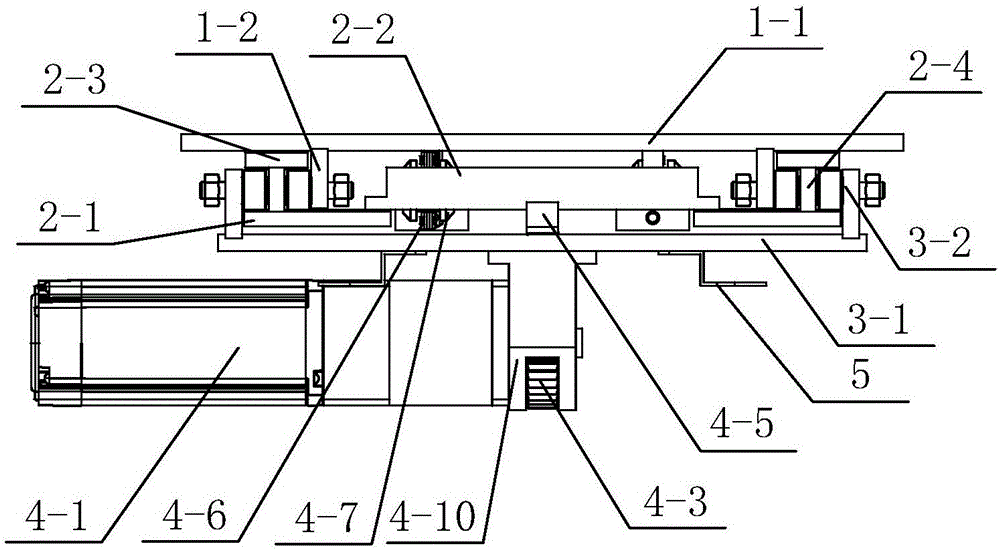

[0032] Example: such as Figures 1 to 9 As shown, a loading platform includes a top plate 1-1 installed on the upper end, a top plate support plate 1-2 that moves in the same direction following the top plate 1-1, a bottom plate 3-1 installed on the lower end, and a driving mechanism. The above-mentioned top plate The support plate 1-2 is installed under the top plate 1-1 to support the above-mentioned top plate 1-1, the driving mechanism is installed between the top plate 1-1 and the bottom plate 3-1, and the bottom plate 3-1 is fixedly installed on the stacker. The driving mechanism includes a driving assembly and a transmission assembly. The above-mentioned driving assembly is connected with the transmission assembly and drives the transmission assembly to move through the driving assembly, thereby driving the top plate 1-1 to move, so as to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com