Bent Axis Assemblies for Shades and Bent Axis Shades

A technology of sunshade and bending shaft, applied in the field of sunshade, can solve the problems of poor fit, broken sleeve, weak strength, etc., and achieve the effects of reducing friction and running noise, reducing fit gap, and improving fit accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below with reference to examples. In the preferred embodiment of the present invention, the present invention is described by taking a bent-axis sunshade for a car sunroof as an example. However, those skilled in the art should understand that these exemplary embodiments are not meant to form any limitation to the present invention, for example, the bent axle assembly of the present invention can be used as a window for other vehicles such as trains, cruise ships, or sun rooms, etc. Sunshade for sunroof. In addition, the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

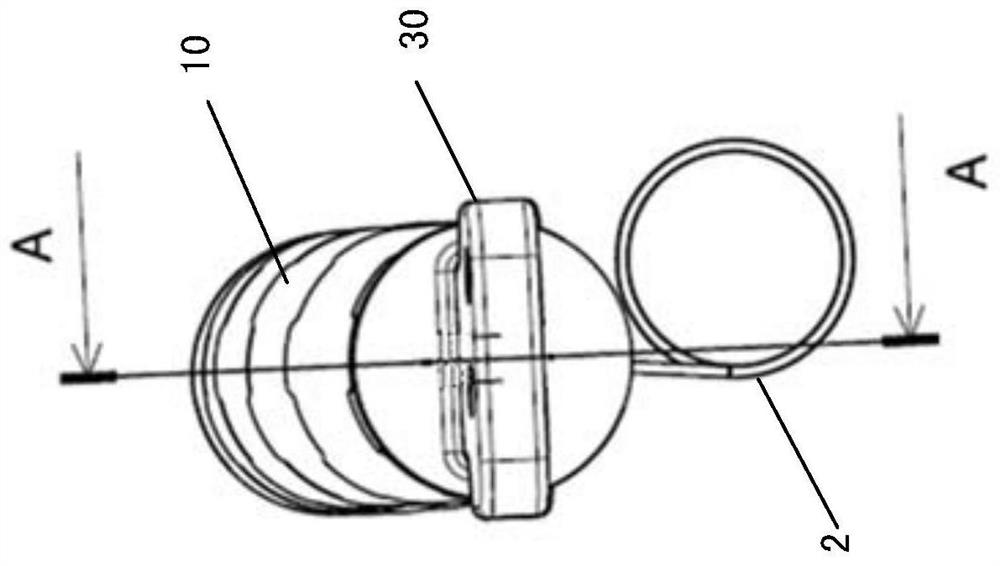

[0040] figure 1 is an isometric view of an assembled bent axle assembly according to an embodiment of the invention. figure 2 yes figure 1 Enlarged left view of the bent axle assembly shown. image 3 is along figure 2 A cross-sectional vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com