Cable shielding assembly and process of producing cable shielding assembly

A component and cable technology, applied in the field of cable shielding components, can solve the problems of heavy metal shields, reduced shielding effectiveness of braids, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Cable shield assemblies and methods of making cable shield assemblies are provided. For example, embodiments of the present invention allow for increased shielding of electronic components, for increased shielding effectiveness at higher frequency ranges, for flexibility, for reduced Manufacturing costs, allow weight reduction of articles including such shields rather than alternative shielding mechanisms, allow for fixing heat recoverable materials without the use of adhesives that adversely increase electrical resistivity, provide protection against electromagnetic interference Shielding, which allows termination and grounding without the use of metal braids, allows other suitable advantages and differences, and allows combinations of the above.

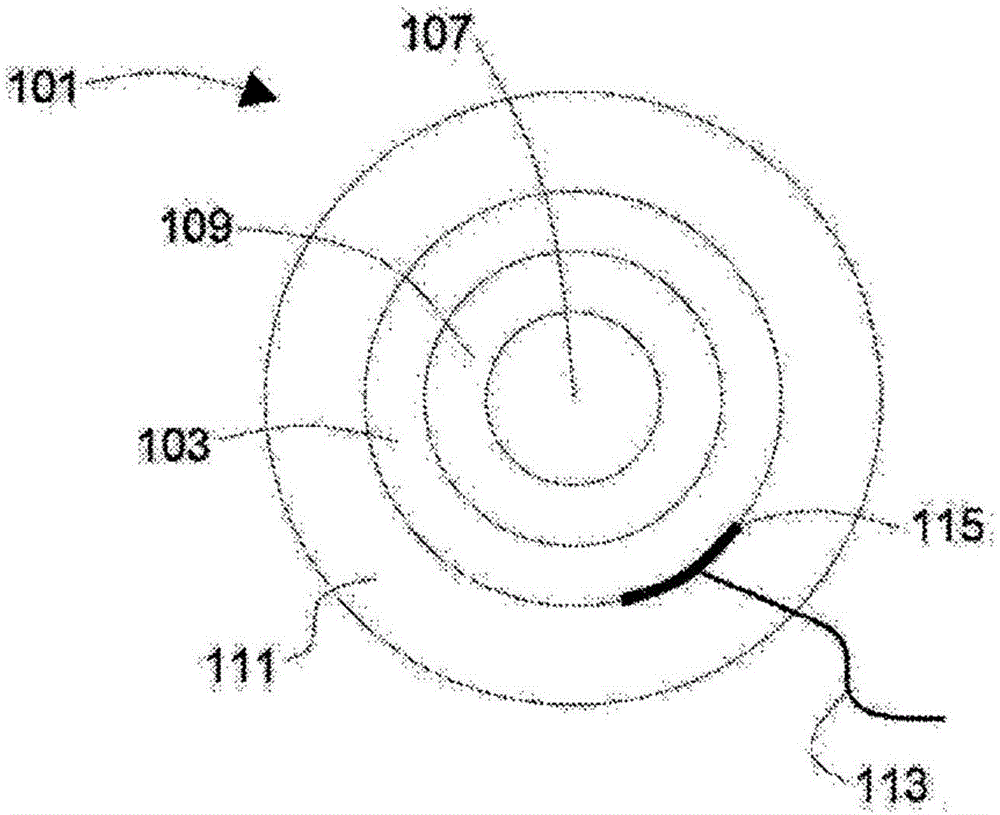

[0014] figure 1 A cable shield assembly 101 is shown that includes a conductor 107 and a conductive composite shield 103 extending around at least a portion of the conductor 107 . The conductive composite shield 103 has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com