A press-fitting tooling and press-fitting process for steering knuckle needle roller bearings

A needle roller bearing and press-fit tooling technology, applied in the field of auto parts, can solve the problems of waste of equipment resources, high labor intensity, high output pressure of the press, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

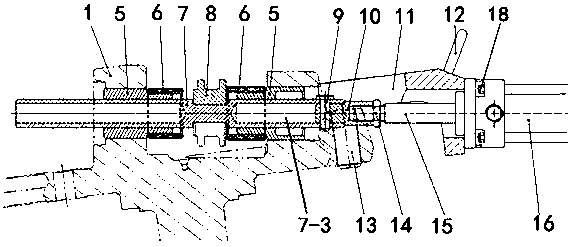

[0032] Specific embodiments: the present invention provides a steering knuckle needle roller bearing press-fitting tool, which includes a fixedly connected power component and a press-fit component, wherein the power component includes an oil cylinder 16 and a connecting plate 11, and one end of the connecting plate 11 is connected to the The steering knuckle 1 is fixedly connected, and the other end is fixedly connected with the oil cylinder 16 through bolts 18. The press-fit parts include a guide rod 7 and a guide sleeve 5 and a stopper 8 arranged on the guide rod 7. The guide sleeve 5 is respectively arranged on At the left and right ends of the guide rod 7 , the stopper 8 is arranged between the two guide sleeves 5 , and the telescopic rod 15 of the oil cylinder 16 passes through the connecting plate 11 and is detachably connected with the guide rod 7 .

[0033] In this embodiment, the center of one end of the guide rod 7 close to the oil cylinder 16 is provided with an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com