Apex preheating device and method

A preheating device and technology of apex rubber, applied in the field of rubber production, can solve the problems of poor preheating effect of apex rubber, large surface temperature difference of apex rubber, poor preheating effect, etc., and achieve reasonable preheating time setting, Save manpower and improve the effect of preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

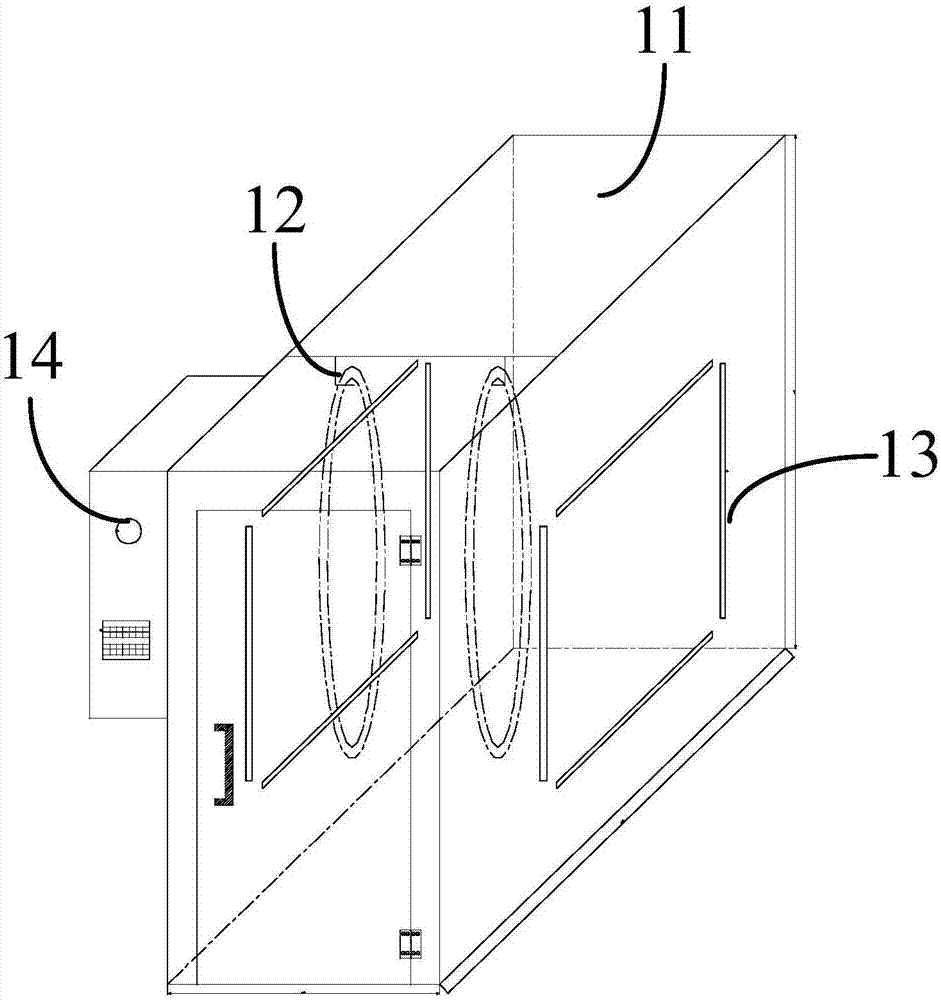

[0024] The purpose of this specific embodiment is to provide an apex preheating device, which can preheat the apex evenly, and can precisely control the timing of completing the apex preheating, and effectively improve the preheating effect of the apex. The purpose of this specific embodiment is also to provide a method for preheating apex rubber based on the above apex preheating device.

[0025] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

[0026] Please refer to figure 1 , the apex preheating device provided by the present embodiment includes a casing 11 and a controller (not shown), wherein the casing 11 has a door, and the casing 11 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com