Precise overprinting and locating device and locating method thereof

A positioning device and positioning method technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of low registration accuracy, and achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

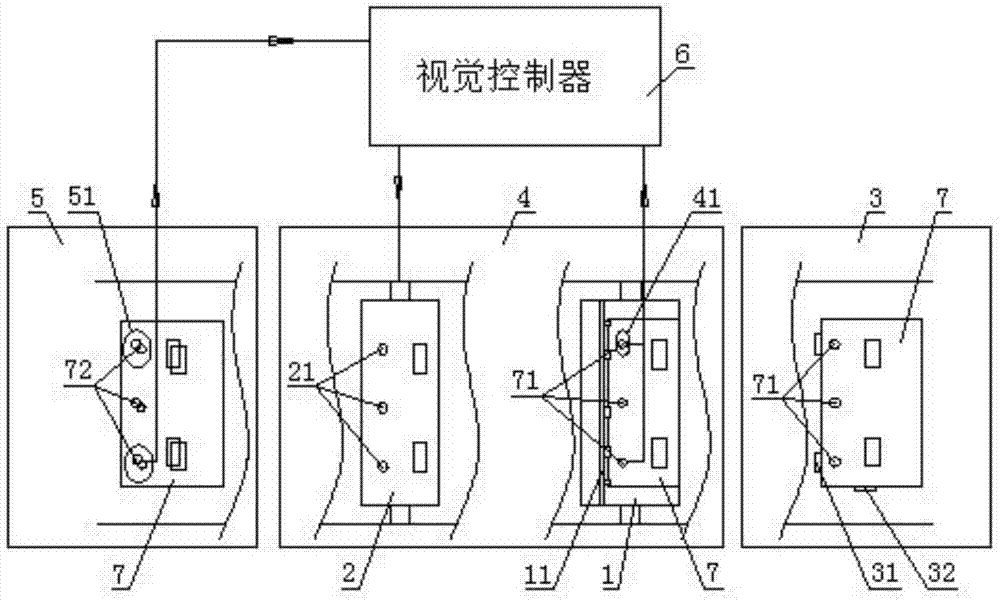

[0026] Such as figure 1 As shown, the present invention includes a longitudinal positioning mechanism 3 arranged before the impression cylinder 1 of the printing equipment, a transverse positioning mechanism 4 arranged at the impression roller 1, an analysis compensation mechanism 5 arranged after the plate cylinder 2 ; Also includes a visual recognition controller 6 connected to the lateral positioning mechanism 4, the analysis compensation mechanism 5, and the printing plate cylinder 2, respectively.

[0027] The invention realizes multiple positioning through the combination of mechanical positioning and automatic visual recognition positioning. The first positioning adopts a mechanical positioning method to achieve precise positioning in the vertical direction and preliminary positioning in the horizontal direction. The second positioning uses a high-definition visual recognition system to achieve precise positioning in the horizontal direction. With compensation and fine-...

Embodiment 2

[0029] The present invention includes a longitudinal positioning mechanism 3 arranged before the embossing cylinder 1 of the printing equipment, a transverse positioning mechanism 4 arranged at the embossing roller 1, an analysis compensation mechanism 5 arranged behind the printing plate cylinder 2; The visual recognition controller 6 connected with the lateral positioning mechanism 4, the analysis compensation mechanism 5, and the printing plate cylinder 2 respectively.

[0030] The invention realizes multiple positioning through the combination of mechanical positioning and automatic visual recognition positioning. The first positioning adopts a mechanical positioning method to achieve precise positioning in the vertical direction and preliminary positioning in the horizontal direction. The second positioning uses a high-definition visual recognition system to achieve precise positioning in the horizontal direction. With compensation and fine-tuning positioning, the position...

Embodiment 3

[0034] On the basis of Embodiment 1 or Embodiment 2, a registration positioning method includes the following steps:

[0035] 1) Mechanical positioning; 2) Visual recognition positioning; 3) Analysis compensation positioning.

[0036] The specific method of step 1) is: first adopt the longitudinal positioning mechanism 3 to carry out mechanical positioning, adjust the front stop gauge 31 of the longitudinal positioning, so that the longitudinal line of the printed sheet 7 printed with the identification mark 71 is in a vertical state with the printing plate cylinder 2; at the same time , adjust the lateral positioning side gauge 32, so that the lateral position of the printed sheet 7 is basically consistent with the position of the printing plate information 21 on the printing plate cylinder 2.

[0037] Through mechanical positioning, adjust the longitudinal positioning front gauge 31 and the lateral positioning side gauge 32, so that the longitudinal line of the printed sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com