Goods collection caching system and feed box storage and sorting system

A cache system and material box technology, applied in storage devices, conveyors, transportation and packaging, etc., can solve problems such as low picking efficiency, and achieve the effect of improving completion efficiency, high storage density, and improving picking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 of the present invention provides a collection buffer system, which is applied to a storage and picking system. The collection buffer system includes at least one modular buffer unit, and the modular buffer unit includes at least one group of order box access shelves, at least one Hoist, at least one shuttle and power station.

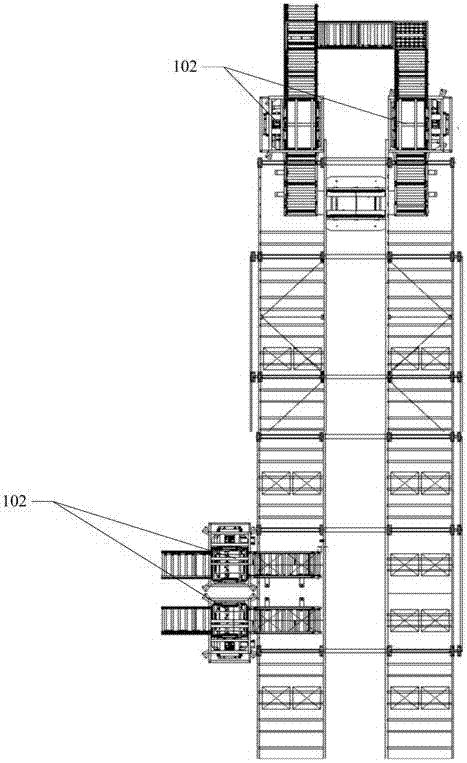

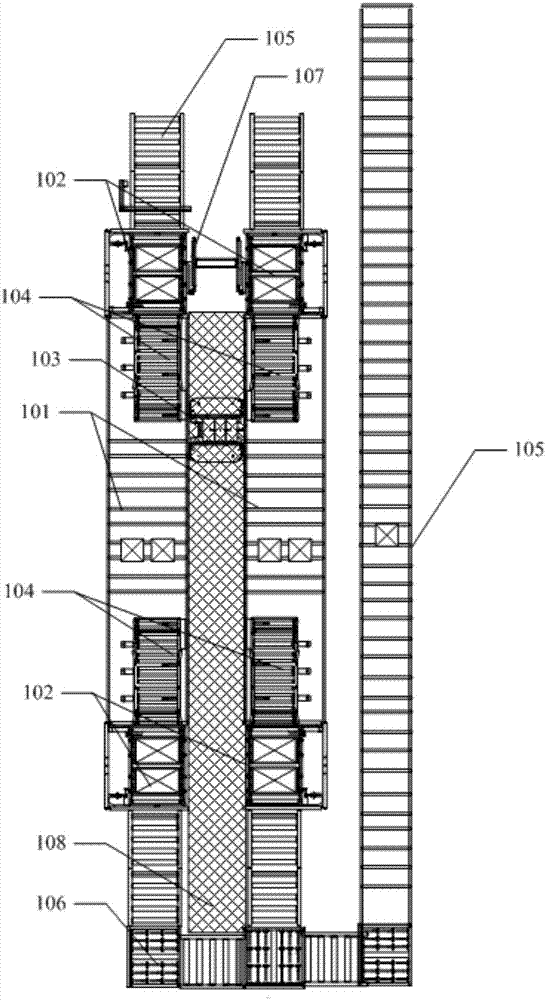

[0037] Among them, the order box access shelf is a dense multi-layer shuttle car shelf, and each shelf includes multiple storage positions; a group of order box access shelves are parallel to each other to form a roadway, and the shuttle car runs in the roadway. see figure 1 The schematic diagram of the structure of the cargo-collecting cache system shown includes one modular cache unit as an example. It can be understood that more modular cache units can be flexibly set up in order to increase the cache space.

[0038] Wherein the modular cache unit includes a group of order box access shelves 101, four elevators 102, a shuttle ca...

Embodiment 2

[0056] Embodiment 2 of the present invention provides a bin storage and picking system, including the collection buffer system provided in Embodiment 1, see Figure 12 The structural block diagram of the shown bin storage and picking system shows that the bin storage and picking system at least includes: Management module 500.

[0057] Specifically, the material box storage module 100 is used for accessing material boxes. Among them, the material box is used for storing goods. What needs to be explained here is that the material box storage module also meets the operating requirements of shuttle vehicles, power platforms, hoists, and maintenance devices.

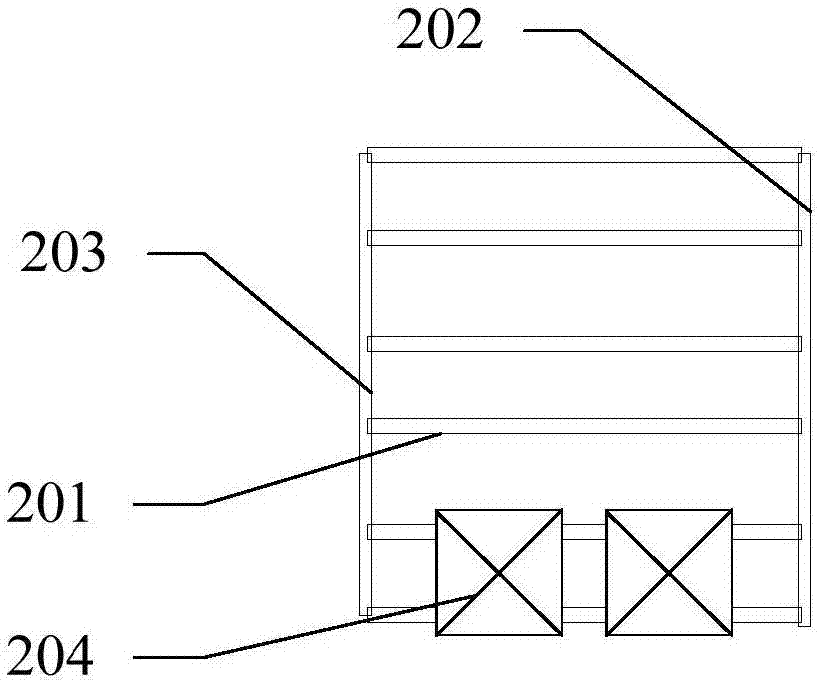

[0058] The batch order picking module 200 is used for parallel picking of batch orders, so as to pick the goods in the material box to the order box. Among them, the batch order is a batch order composed of multiple user orders, and the orders included in the batch order are picked in parallel, that is, the goods informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com