Compound microbial agent for treating manure by ectopic fermentation

A technology of composite microbial agent and manure, applied in the direction of microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of excessive consumption of litter and low decomposition efficiency of manure, and achieve a large amount of water volatilization , Improve the effect of low decomposition efficiency and fast decomposition of manure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Bacteria are mixed and added to the fermenter according to the mass ratio content, composting Bacillus 25%, Geobacillus stearothermophilus 25%, Aerobacillus paleus 25%, Psychrobacter faecalis 10%, Geobacillus thermodenitrophilus Bacillus 15%. Proportioned into a compound microbial agent. Mix the compound microbial agent according to 1kg strain / 3m 3 If the litter volume ratio is added to the ectopic fermentation bed, the amount of bacterial agent added to a single tank is 69kg, and the volume of manure added to each tank is about 4m3 per day. Among them, the construction scale of the fermenter for this test is 45m in length, 3.85m in width, 1.7m in wall height, 40m in length, 1.4m in litter height, and 3.85m in width. 207m3.

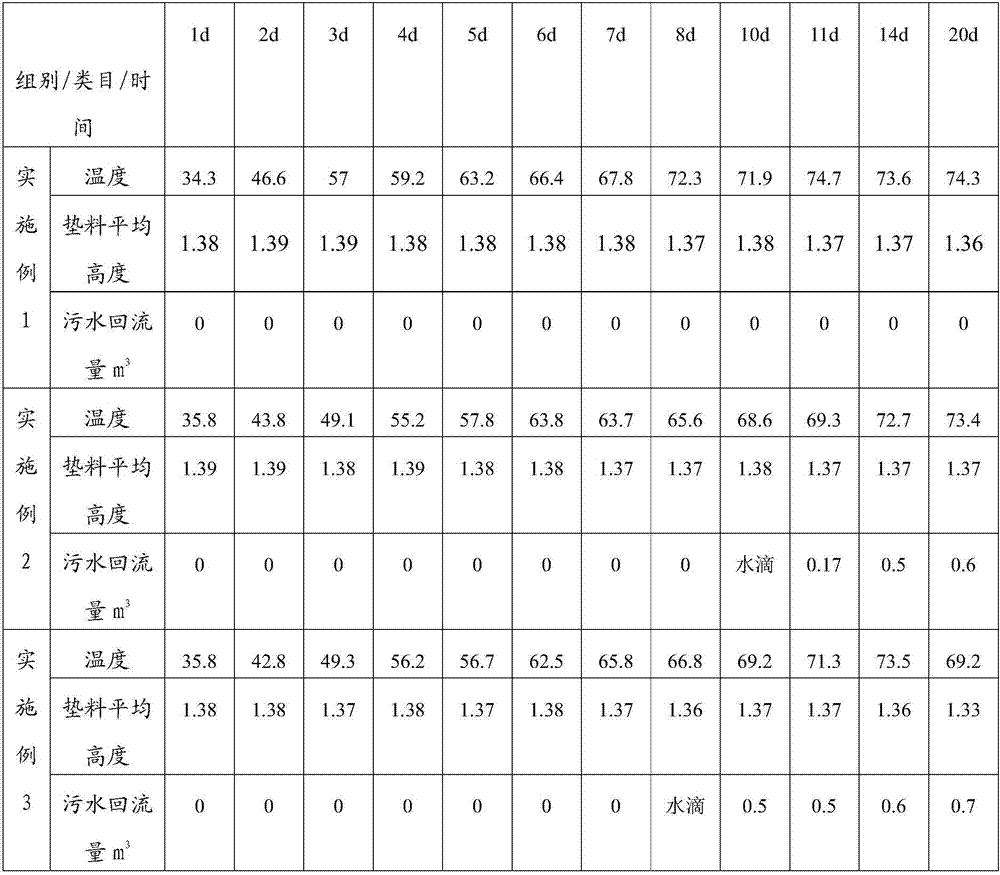

[0042] Measuring results: refer to Table 1 to observe the temperature of the fermentation tank within 20 days. The results show that after adding the compound microbial bacterial agent and adding manure to the litter in Example 1, the amount of ...

Embodiment 2

[0044] Repeat Example 1, and Example 2 has the following differences, which are mainly reflected in the differences in the composition of the compound bacterial agent: 25% of composting bacillus in situ, 25% of Geobacillus stearothermophilus, 20% of Aerobacillus pallor, 20% of feces 10% Psychrophilic Bacillus, 20% Thermodenitrophilic Geobacillus.

[0045] Measuring results: refer to Table 1 to observe the temperature of the fermenter within 20 days. The results show that the temperature in the fermenter in Example 2 can rise to the start-up temperature (55°C) on the fourth to fifth day, and measure 55.2°C on the fourth day. Example 1 Add about 4m3 of feces every day under the same operating conditions. During the observation period of 20 days, there is no obvious irritating smell in the ectopic fermentation house. On the 10th day, droplet sewage began to seep out of the backflow tank until 14 days The first measurement of the return flow of sewage in the reflux tank was 0.5m3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com