Ultrasonic flaw detection device for steel rail base metal rail flange

A flaw detection device and ultrasonic technology, which are applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, and material analysis, etc., can solve the problems of not ensuring flaw detection quality, affecting rail flaw detection, affecting rail transportation safety, etc., and achieving flaw detection process. Smooth and reliable, convenient and quick to adjust, easy to install and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

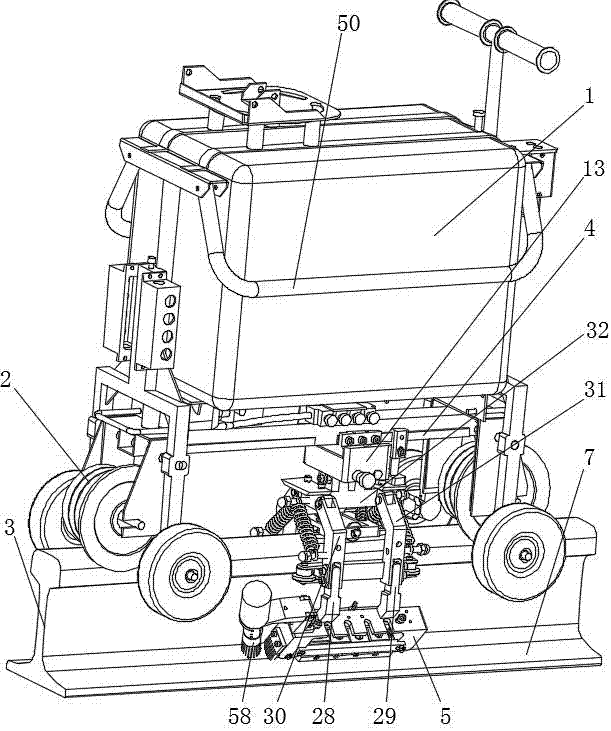

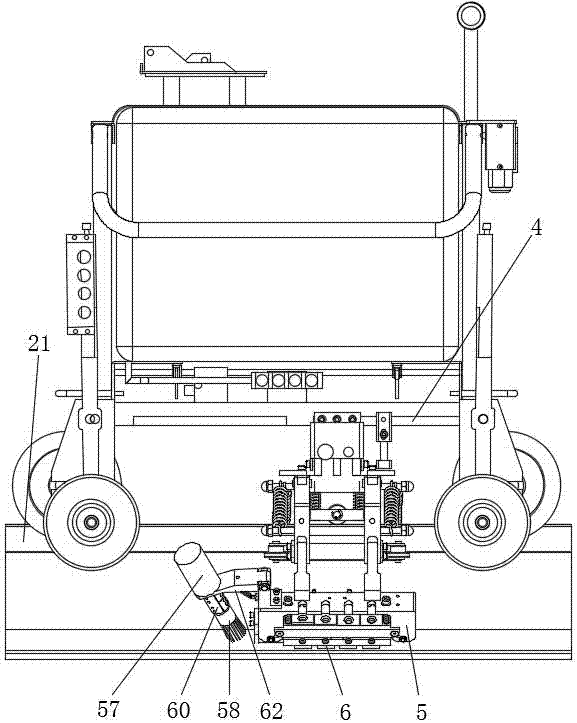

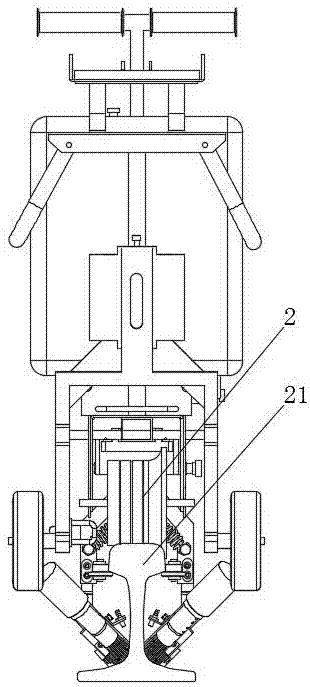

[0033] Such as Figures 1 to 5As shown in . and 9, an ultrasonic flaw detection device for rail bottom of a rail parent material, including a trolley 1 and a flaw detection structure, the front and rear ends of the bottom of the trolley 1 are provided with track wheels 2, and the track wheels 2 are supporting rolling wheels for the trolley 1 on the tread surface of the rail 3 , to support and guide the trolley 1 moving forward on the rail 3. The flaw detection device also includes a clamping mechanism. The clamping mechanism is arranged on the crossbeam 4 at the bottom of the trolley 1 and can be slid and adjusted longitudinally relative to the crossbeam 4. The flaw detection structure is connected to the clamping mechanism. the lower part of the institution;

[0034] The flaw detection structure includes two sets of probe racks 5 arranged on both sides of the rail 3 and probes 6 installed in the probe racks 5. When the flaw detection device is installed on the rail 3, the cor...

Embodiment 2

[0043] Such as Figures 1 to 9 As shown, on the basis of Embodiment 1, the flaw detection device also includes a landing mechanism. The landing mechanism includes a landing gear mounting seat 32, a front landing gear 30, and a rear landing gear 31. The landing gear mounting seat 32 is fixedly connected to the compensation rod 20. 1. One end of the rear landing gear 30,31 is rotatably connected to the front and rear ends of the landing gear mount 32 respectively. Symmetry, the other end of the front landing gear 30 is connected with the front connecting rod 28, the other end of the rear landing gear 31 is connected with the rear connecting rod 29, and the front and rear connecting rods 28, 29 are respectively on the front and rear landing gears 30, 31. The installation height is adjustable, and the flaw detection structure is fixedly connected with the front and rear connecting rods 28, 29, that is, the two sets of probe racks 5 are fixedly connected with the corresponding fron...

Embodiment 3

[0050] Such as Figures 1 to 3 , 9, in order to make the flaw detection effect better, on the basis of Embodiment 2, the front end of the probe frame 5 is provided with a rail 3 cleaning structure, and the rail 3 cleaning structure includes a motor 57, a steel brush head 58 and a motor fixing seat 59, and the motor 57 is set on the front end of the probe frame 5 through the motor fixing seat 59, and the steel brush head 58 is connected to the end of the motor 57 through the coupling 60. Downward automatic compensation adjustment; it also includes a brush 63 arranged on the front end of the probe frame 5, the brush 63 is located behind the steel brush head 58, and the brush 63 is closely attached to the area to be tested; specifically, the motor 57 passes through the motor mounting plate 64 is connected with motor mount 59, and motor 57 is fixedly mounted on the front end of motor mounting plate 64, and the rear end of motor mounting plate 64 is connected with motor mount 59 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com