A mechanically sealed high-pressure capillary gas circuit device

A mechanical seal, high-pressure hair technology, applied in mechanical equipment, hose connection devices, pipes/pipe joints/fittings, etc., to achieve the effect of less assembly time, high success rate, and easy bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The technical solution of the present invention will be further described below with reference to the drawings and embodiments.

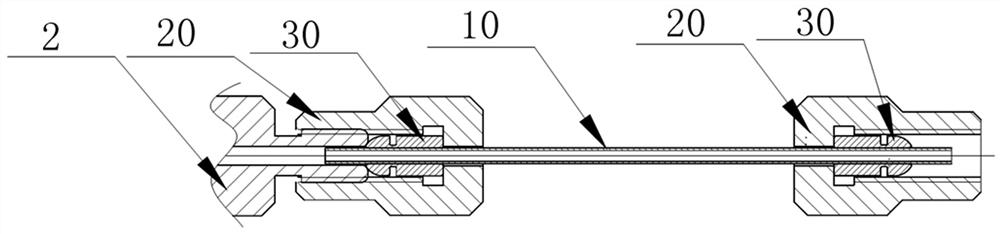

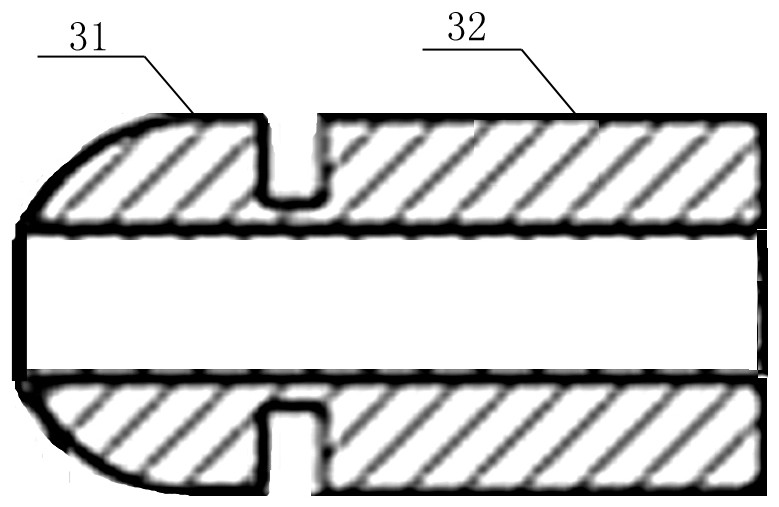

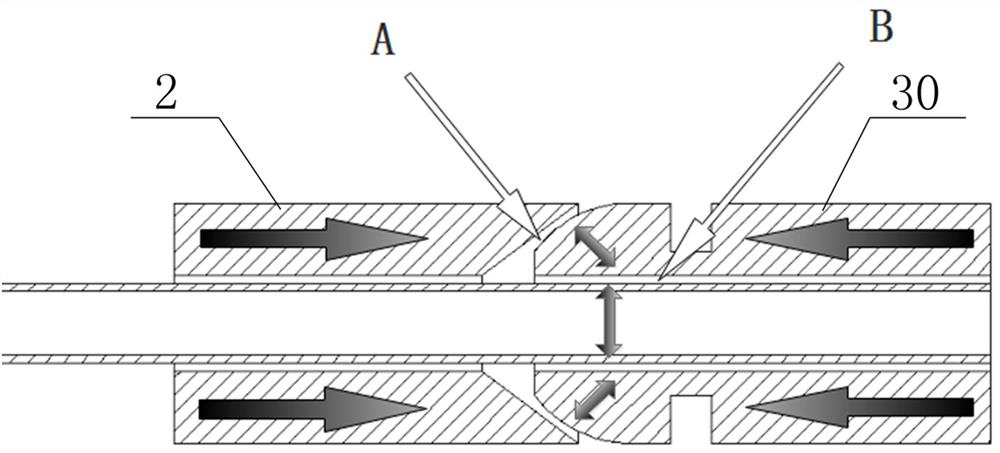

[0034]A mechanically sealed high-pressure capillary gas path device, such asfigure 1 Shown is a schematic structural diagram of the mechanically sealed high-pressure capillary gas path device of the present invention. The device is used to connect and seal the simulation test equipment and the high-pressure gas refrigeration device. The device includes: capillary high-pressure gas pipes 10, respectively passing through the capillary high-pressure Two jacket nuts 20 at both ends of the air pipe 10 and a ball seal 30 arranged in the jacket nut 20 and surrounding the outer wall of the capillary high-pressure air pipe 10.

[0035]Both ends of the capillary high-pressure air pipe 10 are arranged outside the ball seal 30. The device is connected with the simulation test equipment and the high-pressure gas refrigeration device through the jacket nut 20.

[0036]Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com