Treatment apparatus and process for in-kiln balling and firing ceramsite from industrial waste residue and sludge

A technology of industrial waste slag and ceramsite, applied in clay products, other household utensils, household utensils, etc., can solve the problems of high product cost, large ceramsite ball shape, high drying cost, etc., and achieve simplified production process and moisture content requirements Low, the effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

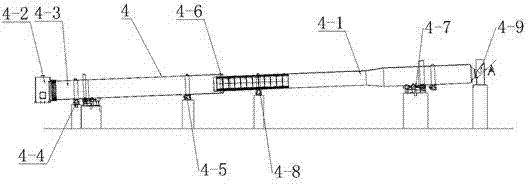

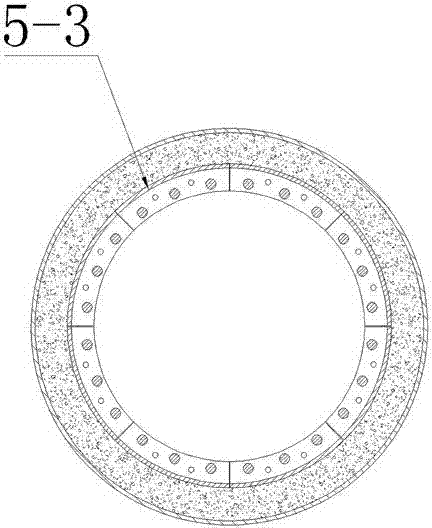

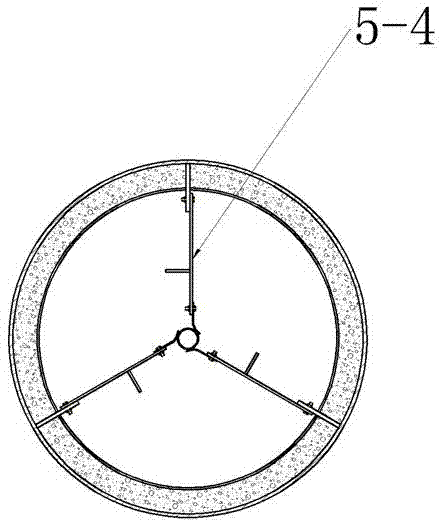

[0030] Such as Figure 1-Figure 7 Shown, the present invention a kind of kiln into ball industrial waste residue and sludge firing ceramsite disposal equipment, it comprises two-way shaft mixer 1, two-axis kneader 2, burning device 3, ceramsite rotary kiln 4 and ceramsite rotary kiln The kiln 4 feeds the mobile kiln screw machine, and the ceramsite rotary kiln 4 adopts the ball forming device 6 in the kiln. The combustion device is arranged in the ceramsite calcining kiln, and is connected with a fuel bin and a fuel metering screw machine through a fuel feeding device. The ceramsite rotary kiln 4 includes the ball forming and drying kiln 4-1 in the ceramsite kiln, the kiln head cover 4-2 equipped with a sealing device, the ceramsite calcining kiln 4-3, and the ceramsite calcining kiln 4-3. The two ends are respectively equipped with supporting wheel device 1-4 and supporting wheel device 4-5 with retaining wheel. The ball forming device in the kiln is set in the ball forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com