Efficient horizontal type montmorillonite dryer

A montmorillonite and dryer technology, applied in dryers, drying solid materials, drying and other directions, can solve problems such as unfavorable finished product quality, affecting drying effect, etc., to achieve good drying effect, ensure drying performance, and improve drying. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

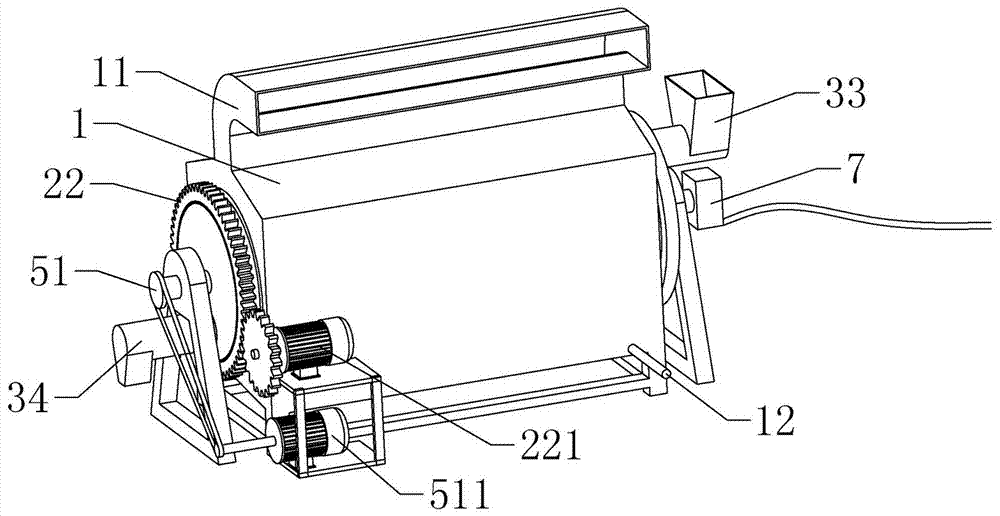

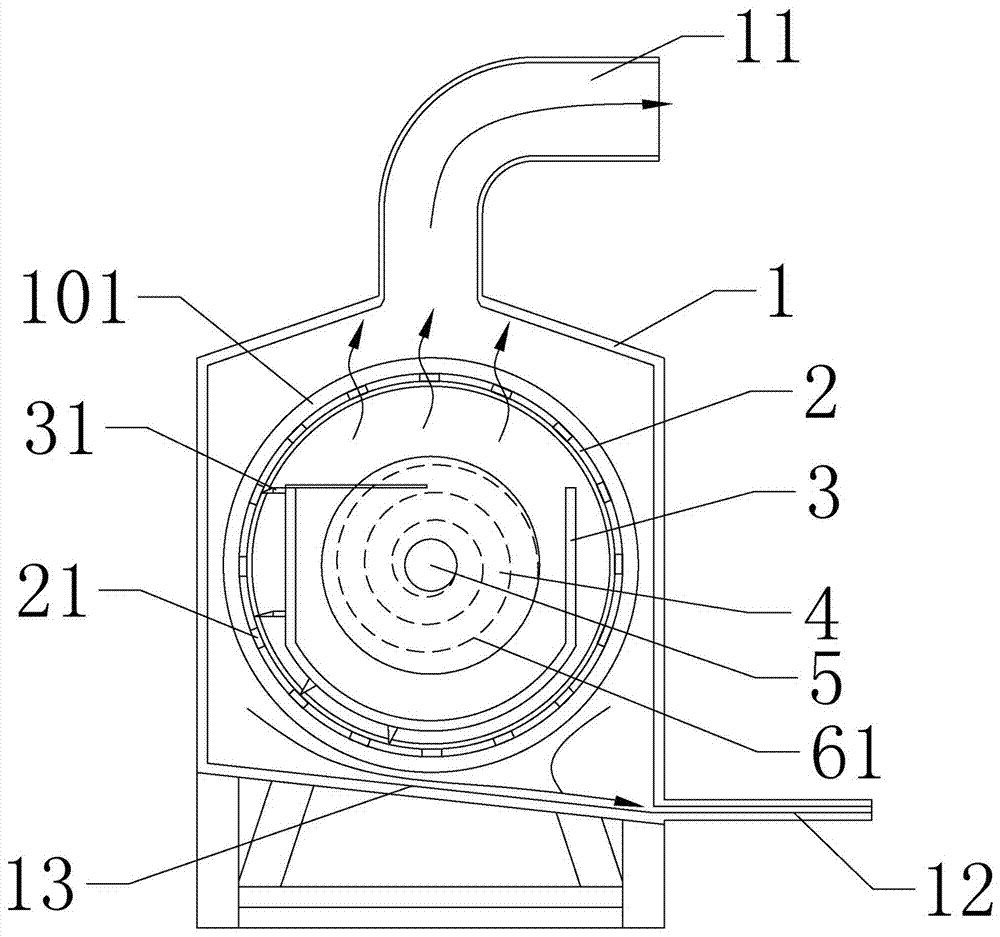

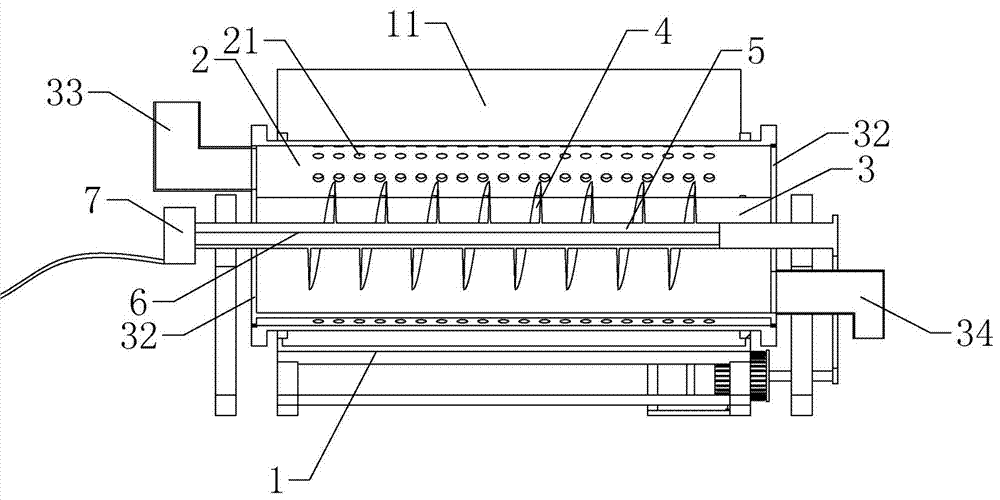

[0028] according to Figure 1 to Figure 6 As shown, a high-efficiency horizontal montmorillonite dryer includes: an air extraction shell 1, a rotating jacket 2, a material holding basket 3, a heating spiral disc 4 and an inner rotating shaft 5 arranged sequentially from the outside to the inside; the air extraction shell 1 The top is provided with an air extraction pipeline 11 , the bottom is provided with a drain pipe 12 , and the bottom of the air extraction shell 1 is provided with an inclined platform 13 , and the drain pipe 12 is connected to the lowest point of the inclined platform 13 . The rotating jacket 2 is hollow cylindrical, and its side wall is provided with an exhaust hole 21 , and the exhaust hole 21 penetrates the side wall of the rotating jacket 2 . The material holding basket 3 is set in the rotating jacket 2, the top is open, the bottom and the side are sealed, the bottom and the side facing the rotating jacket 2 are provided with a water vapor scraper 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com