Montmorillonite drying device

A drying device and montmorillonite technology, applied in heating devices, drying solid materials, drying, etc., can solve the problems of unfavorable finished product quality and affecting drying effect, achieve good drying effect, ensure drying performance, and improve drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

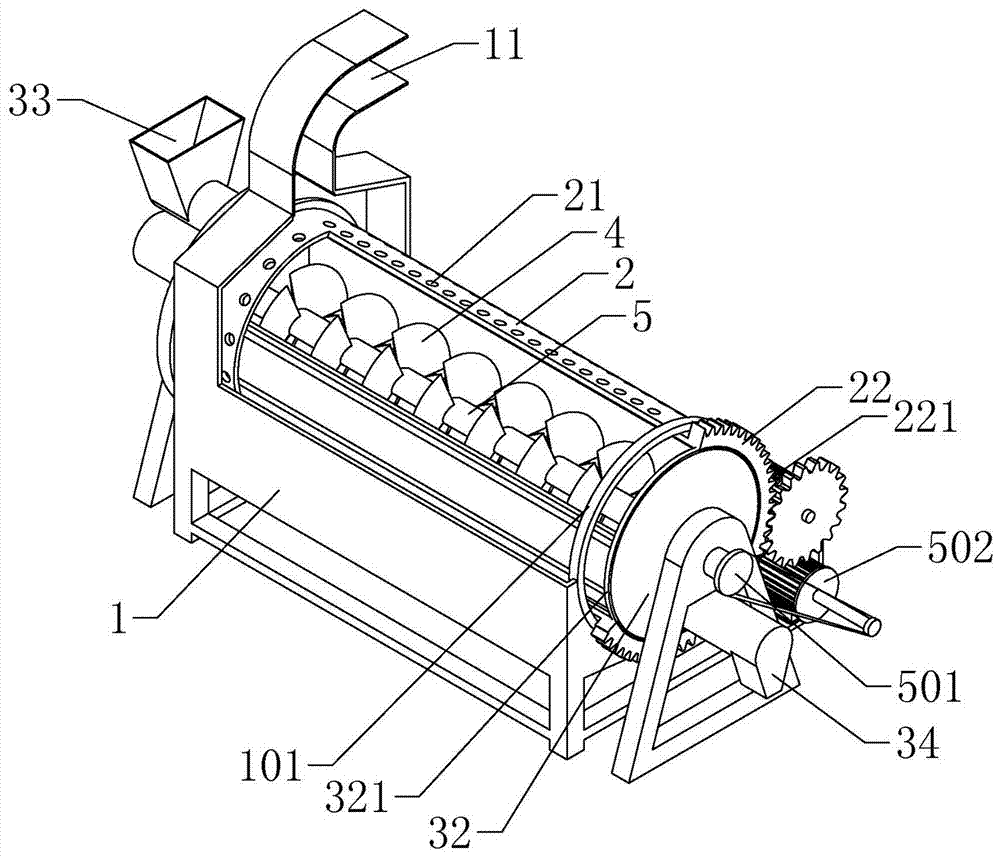

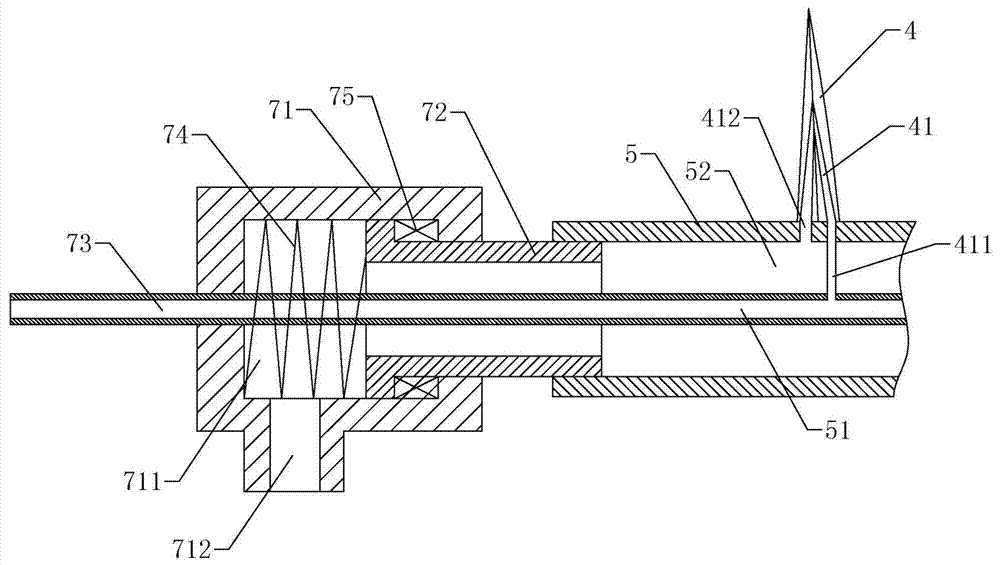

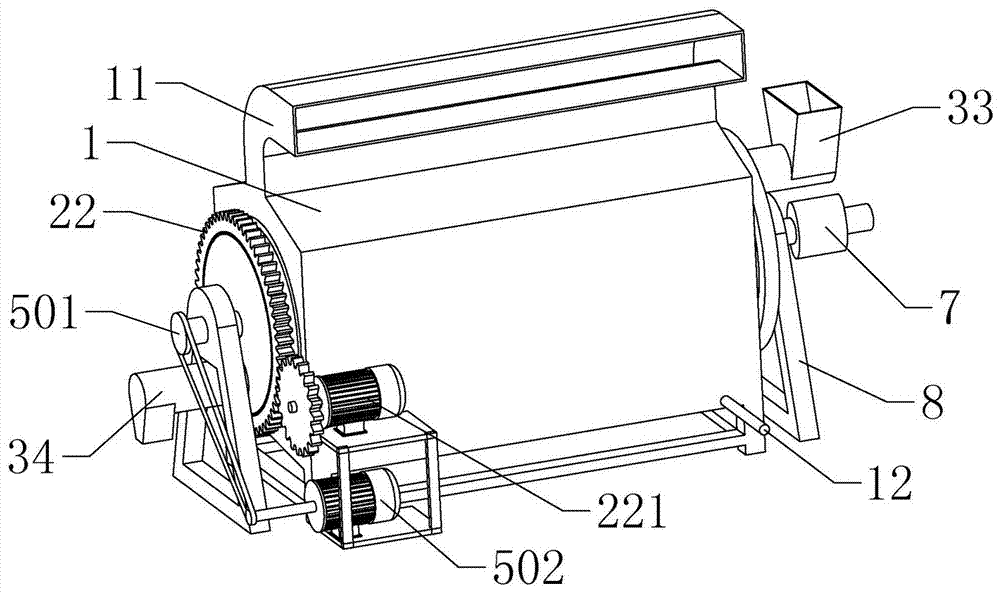

[0029] according to Figure 1 to Figure 5 As shown, a drying device for montmorillonite includes: an air extraction shell 1, a rotating jacket 2, a material holding basket 3 and an inner rotating shaft 5 arranged sequentially from the outside to the inside. The inner rotating shaft 5 is fixed with heating blades 4, and the rotating shaft A steam pipe 51 and a condensed water pipe 52 are arranged inside, the steam pipe 51 is sleeved in the condensed water pipe 52, and the heating blade 4 is provided with a heating pipe 41 communicating with the steam pipe 51 and the condensed water pipe 52; Pipeline 11 is provided with drainage pipe 12 at the bottom, and inclined platform 13 is provided at the bottom of air extraction shell 1 , and drainage pipe 12 is connected at the lowest point of inclined platform 13 .

[0030] The section thickness of the heating blade 4 gradually decreases from its root to its top, and the heating blades 4 are evenly distributed in groups of 3 in the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com