A precise visual inspection system and method for concave-convex defect of flexible IC substrate

A visual detection and flexible technology, applied in the field of defect detection, can solve problems such as insufficient distinguishability and insufficient accuracy of classification and recognition results, and achieve the effect of good recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

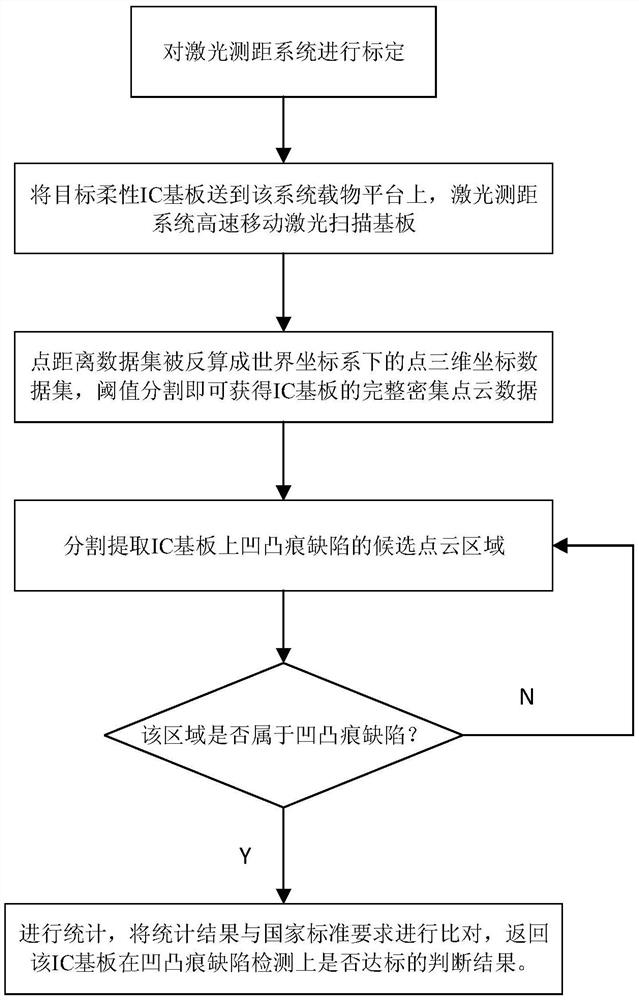

[0052] Such as figure 1 As shown, the precise visual detection method of the flexible IC substrate concave-convex defect of the present embodiment includes the following steps:

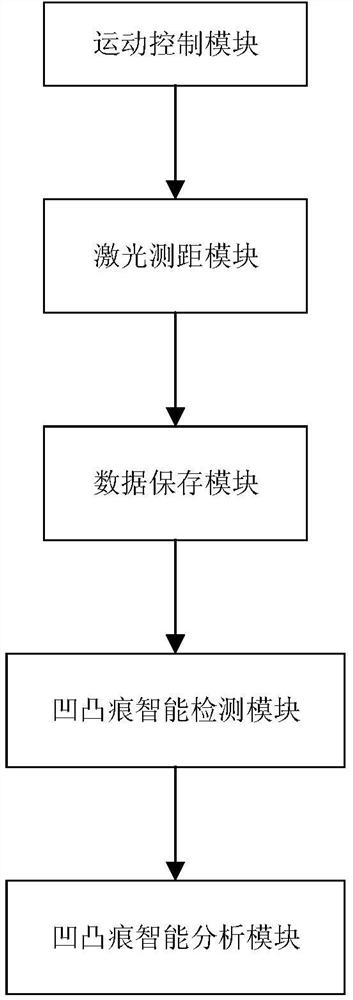

[0053]S1. Calibrate the laser ranging system (which can be composed of a motion control module, a laser ranging module and a data storage module) to adjust the final installation angle of the point laser generator;

[0054] S2. Send the target flexible IC substrate to the loading platform of the system, the laser ranging system moves the laser to scan the substrate at high speed, and finally returns the point distance data set within the measurement range including the substrate;

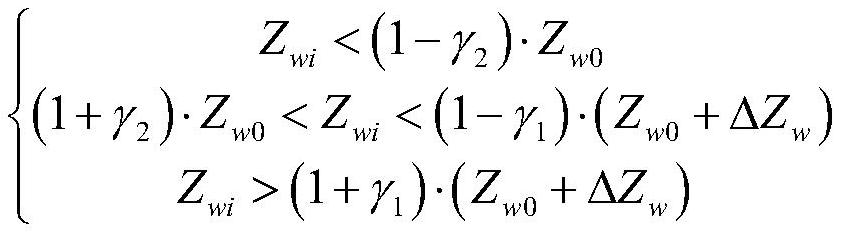

[0055] S3. The point distance data set is back-calculated into a point three-dimensional coordinate data set in the world coordinate system through the concave-convex mark intelligent detection module, and the complete dense point cloud data of the IC substrate can be obtained by threshold segmentation;

[0056] S4. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com