Device convenient for steel pipe welding and welding method

A technology that facilitates steel pipes and steel pipes. It is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc. It can solve the problems that the truss segments or pieces cannot be placed in the designated positions, it is difficult to ensure the installation accuracy, and there are potential safety hazards. Effects of labor productivity, reduction of potential safety hazards, and saving of installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

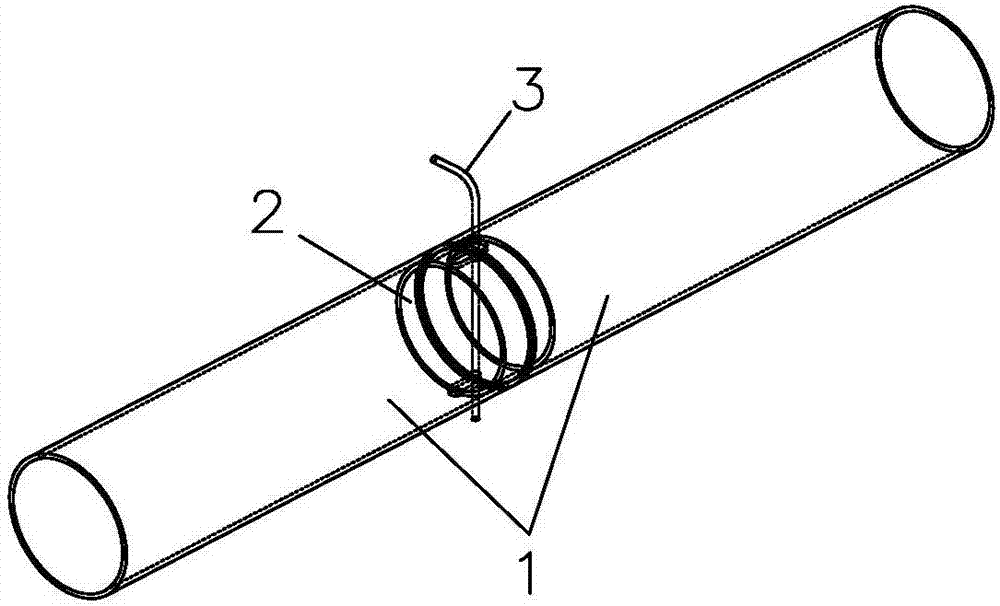

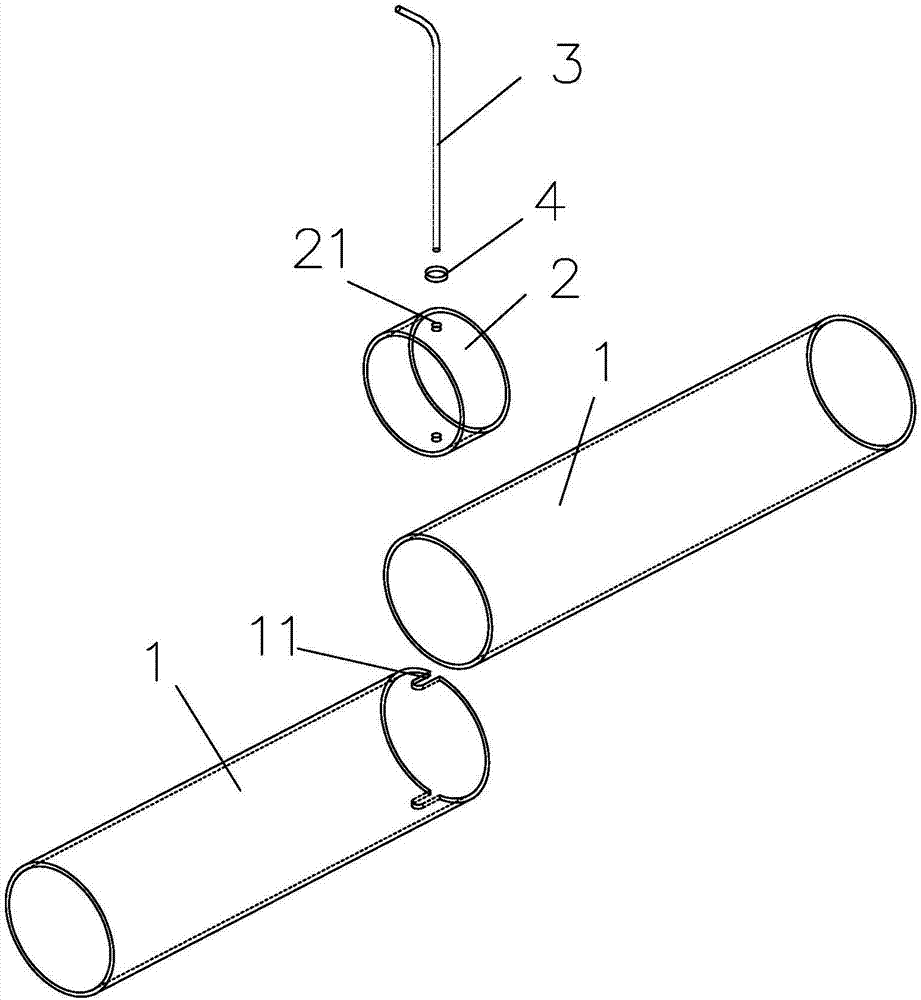

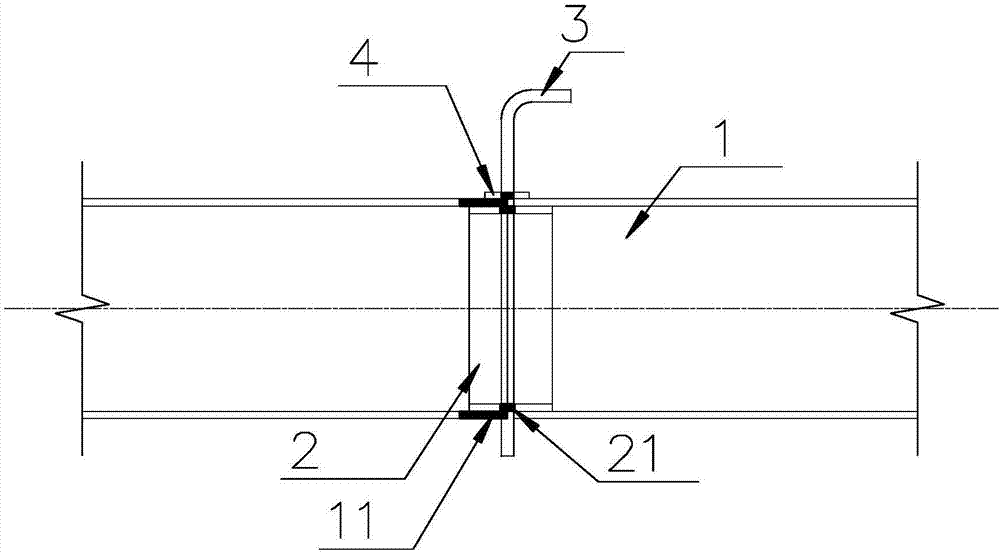

[0017] Such as Figure 1 to Figure 4 , a device for convenient welding of steel pipes, comprising a welding liner 2 and a steel pipe 1 to be welded, the steel pipe 1 to be welded is provided with two chute 11 on the welding end, one end of the chute 11 is open and arranged along the axial direction, The two chutes 11 are arranged symmetrically along the axis of the steel pipe. The outer diameter of the welded liner 2 matches the inner diameter of the steel pipe to be welded. There are two symmetrical sockets 21, the sockets 21 are inserted with pins 3, the pins 3 pass through the two sockets and both ends of the sockets 21 are exposed to form a slide bar, and the welding ends of the two steel pipes 1 to be welded pass through The welded liner 2 is connected, and the bolt 3 on the welded liner is clamped in the chute of the steel pipe to be welded. The plug is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap