Open Fixture System for Aeronautical Complicated Parts and Its Application Method

A technology of complex parts and fixture systems, applied in metal processing machinery parts, clamping, manufacturing tools, etc., can solve problems such as long time-consuming locking and positioning, interference between tools and fixtures, complicated tooling process, etc., to reduce time and increase Effect of Machinable Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

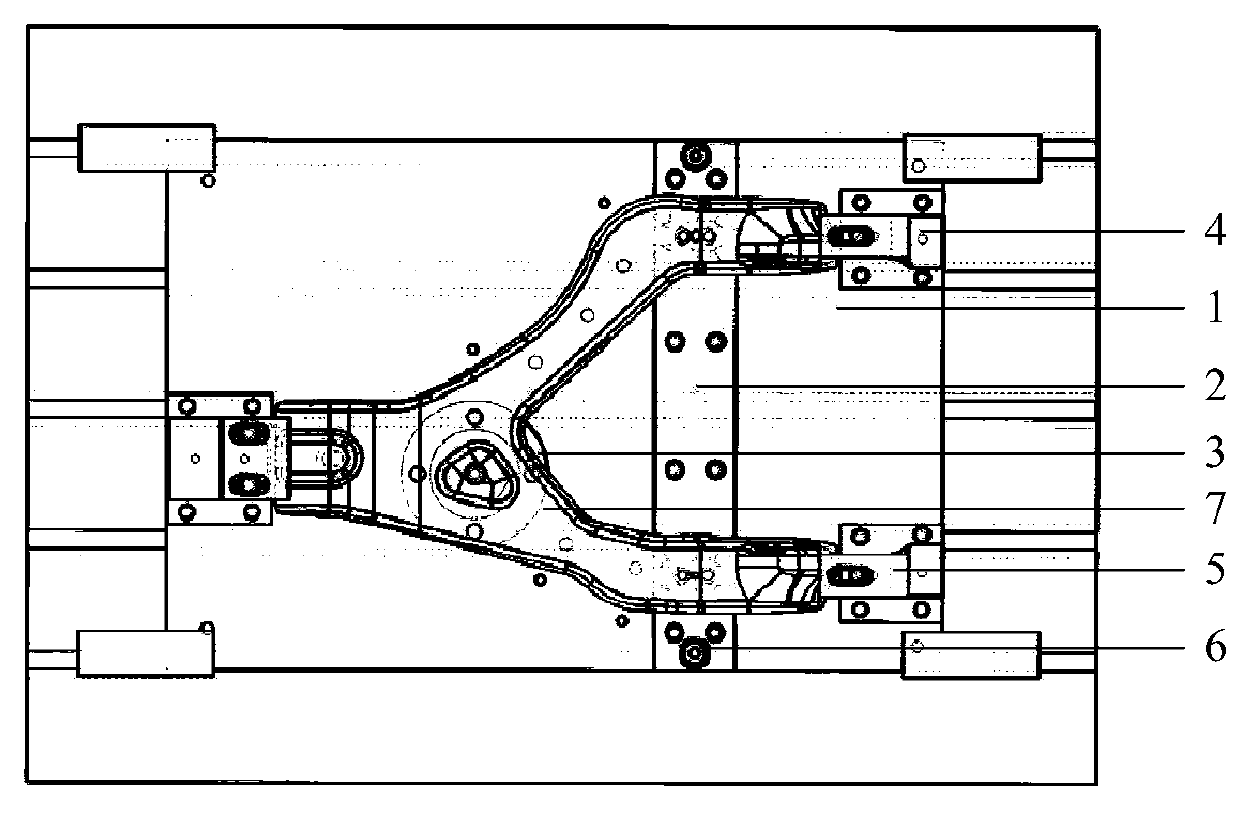

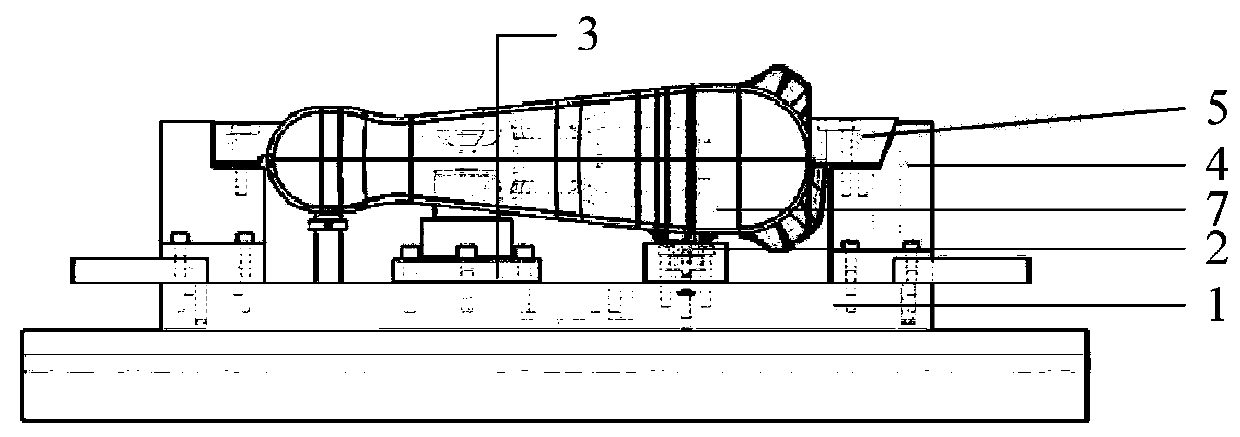

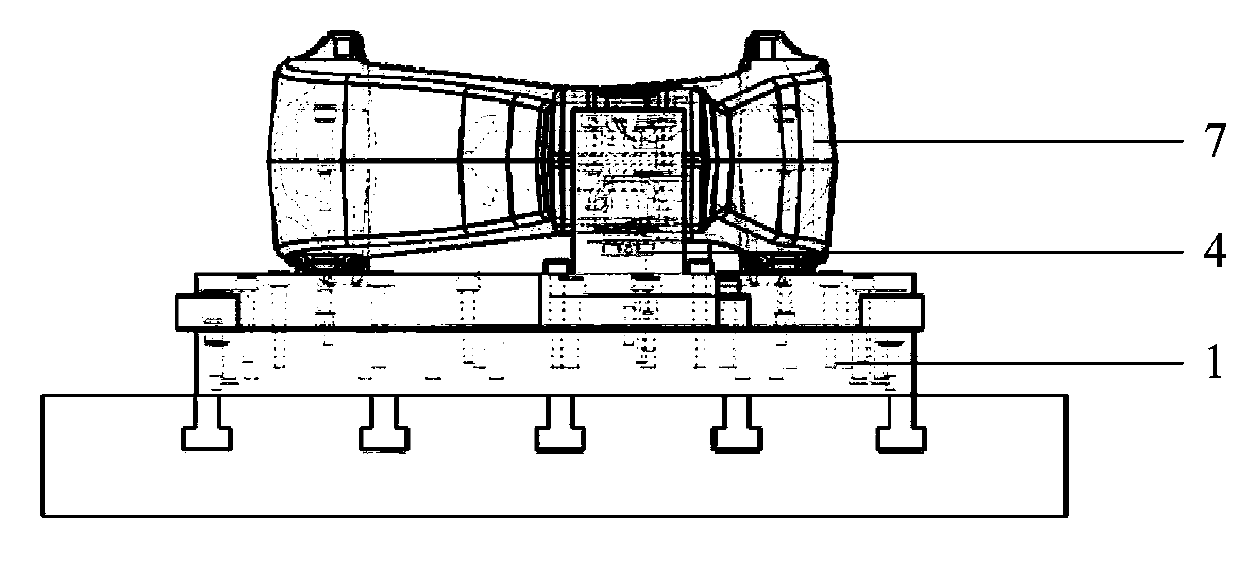

[0033] Such as Figure 1 to Figure 6 As shown, the present invention provides an open fixture system for aviation complex parts, including a base plate 1, a process boss, and a plurality of pressing blocks. The base plate 1 is fixed on the machine tool table, and the process boss and the pressing blocks are both It is fixed on the base plate, and the aviation complex part 7 is positioned and pressed on the base plate 1 through the process boss and the pressing block.

[0034] Wherein, the process boss includes a strip boss 2 and a cylindrical boss 3, and the strip boss 2 is fixed on the base plate 1 by pins;

[0035] Aviation complex parts 7 are positioned through two pins on the elongated boss 2, and the upper surfaces of the elongated boss 2 and the cylindrical boss 3, and through the screws on the cylindrical boss 3 and the pins on the elongated boss 2. Fasten the screws on it.

[0036] Wherein, a pin hole 6 is provided at both ends of the strip boss 2, and the aviation c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap